- The Other Glass Machinery

- Aluminum Window Machine

- UPVC PVC Window Machine

- CNC Non-Metal Cutting Machine

- CNC Glass Working Center

- Glass Drilling Machine

- Glass Sandblasting Machine

- Glass Laminating Machine

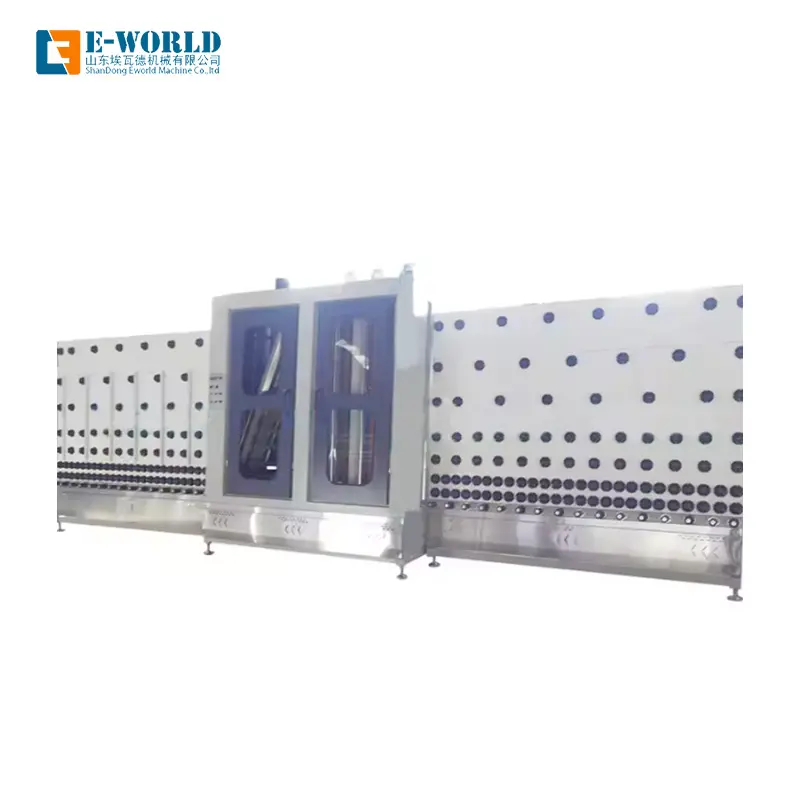

- Glass Washing Machine

- Glass lifting machine

- Insulating Glass Machine

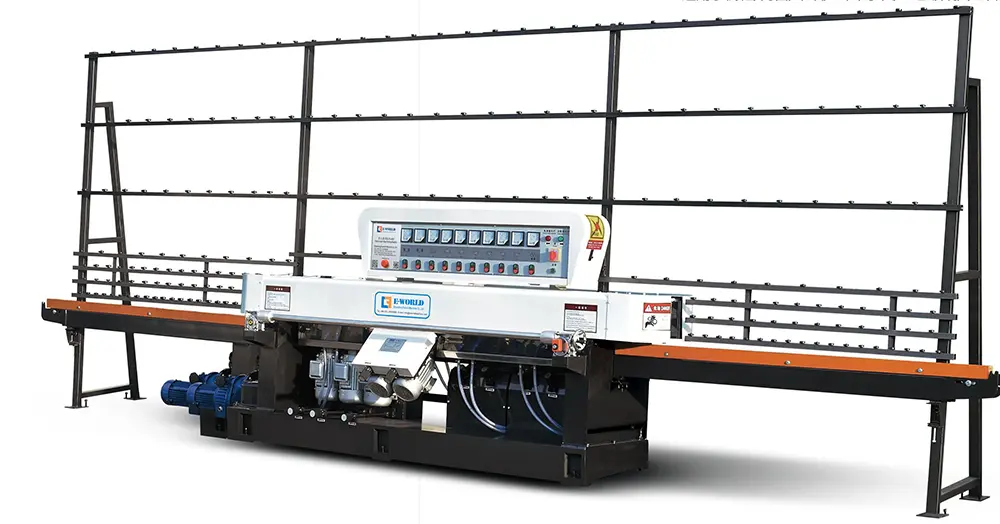

- Glass Edging Machine

- Glass Cutting Machine

0102030405

E-LD9325-45 Glass straight edging machine

Video

Basic Info

|

Model NO.: |

E-LD9325-45 |

|

Price |

|

|

Certification: |

CE |

|

Type: |

|

|

Export Markets: |

North America, South America, Eastern Europe, Southeast Asia, Africa, Mid East, Western Europe |

Additional Info

|

Trademark: |

EWORLD |

|

Packing: |

Packed in Wooden Case, Seaworthy Package |

|

HS Code: |

8464201000 |

|

Production Capacity: |

10 Sets/ Month |

E-LD9325-45 glass straight edging machine

Basic Info

|

Model NO.: |

E-LD9325-45 |

|

Type: |

Glass Edging and Polishing Machine |

|

Export Markets: |

North America, South America, Southeast Asia, Africa, Mid East, Eastern Asia, Western Europe |

|

Packing: |

Packed in Wooden Case, Seaworthy Package |

|

HS Code: |

8464201000 |

Product Description

1. ISO standard.

2. 9 spindles.

3. Excellent grinding and polishing effect.

4. Easy to operate and maintain

5.E-LD9325-45 Glass Straight line Edging Machine, is suitable for processing straight-line edging of glasses.

6. Sturdy structure enables 24 hours running without stop.

7. Hundreds of edging machines have been made and our experience on edging would be shared with you without any reservation.

Functions

Processes rectilinear glass plates in various sizes and thicknesses;

The grinding (roughing), finishing resin and fillets can be performed simultaneously;

The same thickness as the glass sheet can be continuously processed, so that the machine allows having a larger volume of production lines hardening processes, rolling processes and other processing.

Glass type: Float glass for furniture, building, door, windows, home appliances etc

1. Brief introduction

1.1 Complete the coarse grinding, accurate grinding, and polishing of straight-line hemline and corner angle, at a time with different size and thickness of flat glass.

1.2 When adjusting the thickness of the different processing, the pre-chamfering grinding head can be moved synchronously as fore beam.

1.3 Simple to operate and maintain.

1.4 An ideal for the complete processing of glass.

1.5 With 9 spindles, PLC controller if needed.

1.6 Got CE approval, and are strictly according to the CE standard.

2. Technical parameter

Quantity of motors: 9 sets

Feeding speed: 0.5-7m/min

Minimum grinding size: 50mm * 50mm

Thickness of the processed glass: 3mm-25mm

Power: 19.75 kw

Voltage (can be customized-made): 380V/50Hz or customized

Exteanal dimension(L * W * H): 7.0m * 1.0m * 2.5m

Packing size: 3.8m * 1.3m * 1.8m

Weight: 2600kg.

MACHINE PARTS