- The Other Glass Machinery

- Aluminum Window Machine

- UPVC PVC Window Machine

- CNC Non-Metal Cutting Machine

- CNC Glass Working Center

- Glass Drilling Machine

- Glass Sandblasting Machine

- Glass Laminating Machine

- Glass Washing Machine

- Glass lifting machine

- Insulating Glass Machine

- Glass Edging Machine

- Glass Cutting Machine

0102030405

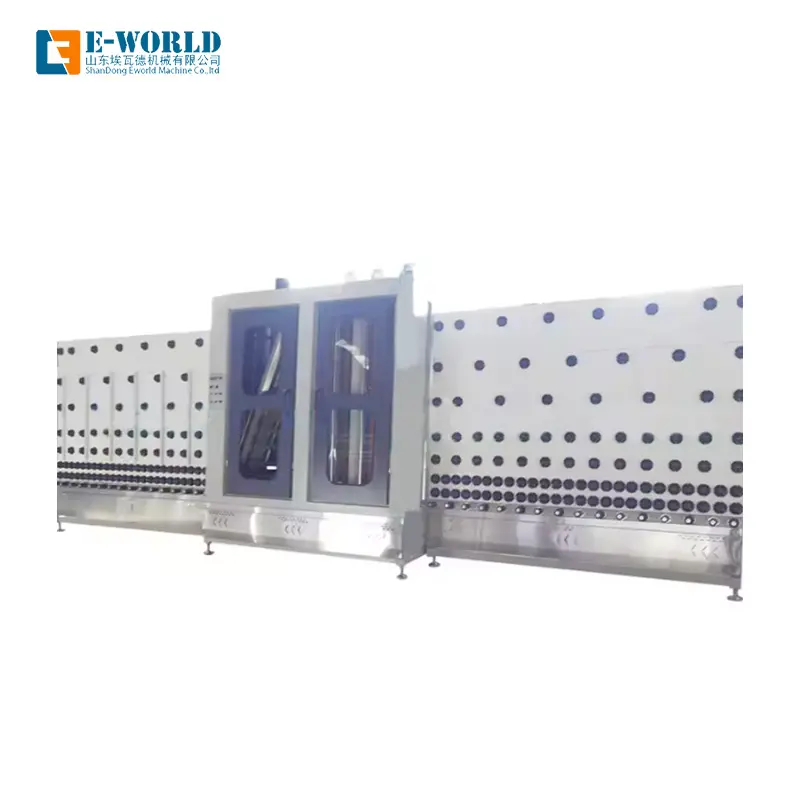

CNC 3726 Conveyor Belt Fully Automatic Glass Cutting Machine

video

Introduction

1) Work flow: After starting the inputting machine, arms automatically suck glass from the shelf. Under sensor controlled, glass automatically find glass edge in the X and Y directions. After moving glass sheets to designated location, transport glass to the automatic cutting table.Cutter will move to coordinate origin, and automatically start to cut according to the preinstall graph.

2)The operator can edit the glass size for cutting with computer. The computer can optimize the cutting size, and give out the data for processing.

Feature

1.Bed using thick wall pipe welding and become, the high temperature tempering treatment, ensure that the deformation is small, rigid good, the intensity is big.

2.The X,Y axis adopt reliable motor drive, selected pairing, ensure the smooth movement.

3.Using high precision level gear rack drive, high precision, speed and strength.

4.Adopts imported linear guide square, high precision, long life.

5.Mechanical and electrical full excellent design, selection of all kinds of electrical accessories, the failure rate drop

6.Software compatibility: compatible type3 / Artcam/Castmate/wentai and so on.Many kinds of CAD/CAM design software.

7.Performance worry about: a breakpoint renewal carving, power off recovery, processing time prediction, and other functions, the real human nature design.

Equipment

1.Equipped with imported cutter wheels and a set of setting tool.

2.A set of stability voltage power supply.

3.A set of best optimized software.

4.A set of computer operating system (including a set of computer and cutting software)

Technical Parameters

1.The cutting thickness: 2-19mm

2.The cutting accuracy: Parallelism:≤±0.15mm/m

3.The cutting speed: 150m/minute(can be adjustable)

4.The outline size:4200*3800*900mm;

5.The max cutting size:3660*2440mm

6.Transmission system: The X、Y、Z Axis are equipped with YASKAWA JAPAN servo motor.

7.The cutter block: It adopt pneumatic and spring at the same time. the cutter holder can rotate by 360°degree, and cut the glass up and down.(It can cut any shape)

8.The oiling supply method: Auto oiling.

9.The transportation device: It adopt Flotation device which makes it convenient to move the sheet glass.

Mechanical

1.The material of the tabletop: Metal tabletop(deformation will not happen)(The smoothness≤±0.2mm/m)

2.Rack/Guides: Imported from Japan and switzerland.

3.Transmission belt/Transmission belt wheels: Italy.

4.Cutter wheels/cutter holder: BOHLE GEMANY.

5.The tabletop: Industrial blankets imported from Korea (color in black).

6.Turret: It use the pneumatic pressure and the spring pressure at the same time to

make the cutting best.

Electrical

1.It’s operated directly by pc and adopt Microsoft Windows.

2.Voltage: 380v/50Hz. It’s equipped with stability voltage device.

3.Motor: Yaskawa servo motor made in Japan(3 sets) and operating card imported from America.

Software

1.Special cutting soft(It can be used under Windows System).

2.There is a graphic library with hundreds of shapes which is convenient for drawing and operating.

3.There is also a set of Auto CAD drawing software.

4.The optimized software can be selected(Enter the size of the sheet glass directly, then it can cut the glass automatically and it’s not necessary to cut by using CAD drawing).

5.There is a function of auto correcting which can make the cutting accuracy high.

6.There is also a selecting function of cutting path.

7.There is also a function of origin point correcting.

8.Operating Entering: Key board and mouse.

Mechanical parts list

|

Name |

Brand |

|

Table surface panel |

High-density waterproof panel, roughness≤±0.20mm/m (Imported material) |

|

Rack and rail |

ALTANTA GEMERGY |

|

Belt/band pulley |

KONYEAR |

|

Cutter wheels and holder |

BOHLE GEMANY |

Electric parts list

|

Name |

Brand |

|

Relay |

OMRON JAPAN |

|

Terminal |

WAGO GERMANY |

|

Air-break switch/low-voltage apparatus/button |

MOELLER GERMANY |

|

Servo motor |

YASKAWA JAPAN |

|

Proportioning solenoid valve |

SMC JAPAN |

|

A.C. contactor |

SCHNERDER |

|

Laser Sensor |

PANASONIC |

|

Position switch |

OMRON |

|

Control card |

GALIL(USA) |

|

Frequency converter |

DELTA |

|

Pneumatic components |

AIRTAC |

|

Optimize Software |

OPTIMA |

Notice

1.It can cut the glass of various thickness and shapes.

2.The seller should supply the services of installation, commissioning and training(in china).

3.Two years guarantee(Not including the artificial damage), long maintenance

Our Corporation

Shandong Eworld Machine Co., Ltd. founded in 2002,has been a high and new technology enterprise specializing in developing, empoldering and selling a series of automatic glass machines, laser engraving machine, Curved Toughened Glass Bending Machine ,window machines and door machines for many years.

Main products: Automatic Laminated glass (various shapes and low-E) production lines, automatic insulating glass production line, glass washing and drying machines, Automatic glass cutting machines, glass engraving machines, laser engraving machine,CNC router machine,CNC Woodworking machine,CNC Advertising machine,PVC window machine,PVC door machine,PVC window and door machine,PVC bending machines,PVC and Aluminum welding machine,PVC and Aluminum cutting saw,corner cleaning machine and other related products.

Advanced products, exquisite techniques, solid working and cordial services all give birth to the unique culture of EWORLD today. EWORLD always keeps step on the latest technology and is committed to providing the most advanced products for our customers. Moreover,EWORLD always emphasizes the training and quality of our staff.

During recent years, our company has taken "customer the highest, technique the first, service following" as our notion, "to be the most customer-oriented and service aware" as our task and "let customer fully know and select the Curved Toughened Glass Bending Machine they need, provide customer the best solutions they need" as our responsibility. Constantly, our company provides high quality services and products for customers. That's why our company receives unanimous trust and good comments from our clients.

Shandong Eworld Machine co.,Ltd ,hopes to set up resplendence with wise people by superior qualitative Curved Toughened Glass Bending Machine and high efficient services.

Working Process