7 Unbeatable Reasons to Invest in the Best Glass Edge Polishing Machine

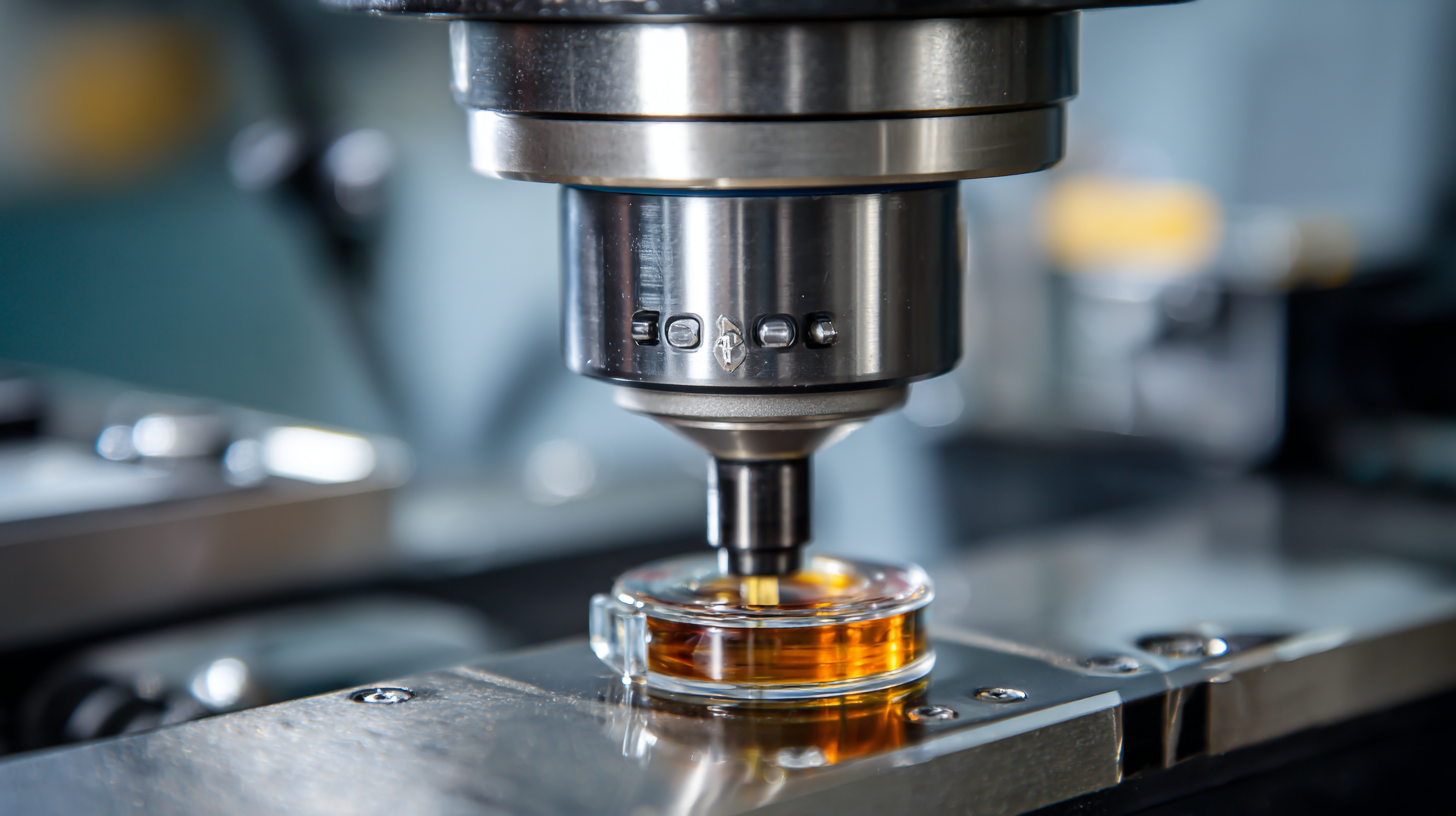

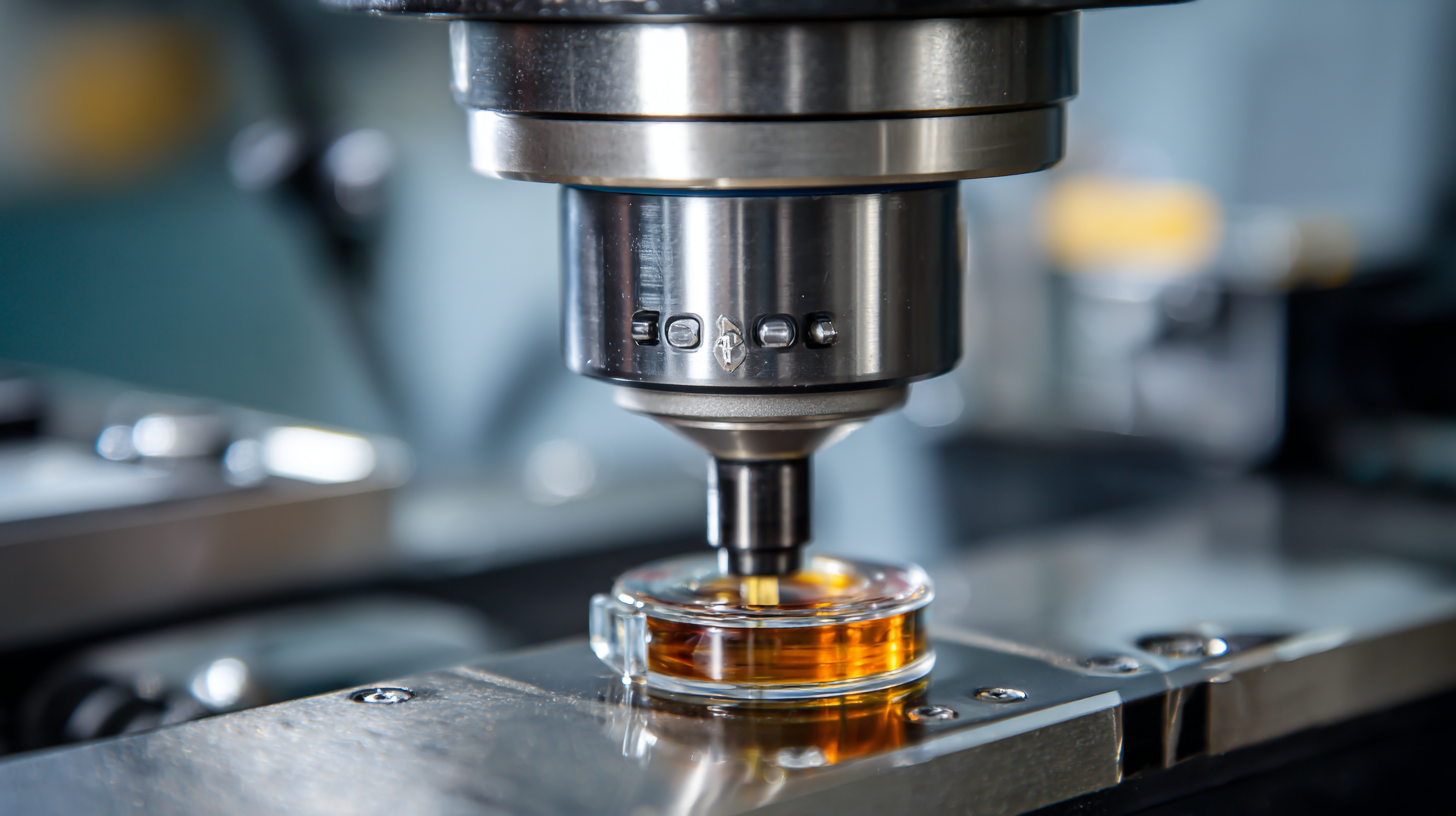

As the global demand for high-quality glass products continues to surge, the significance of advanced manufacturing technologies like the

Glass Edge Polishing Machine cannot be overstated. According to a recent report by

ResearchAndMarkets, the glass processing equipment market is expected to grow at a CAGR of 6.5% from

2021 to 2026, driven by the booming construction and automotive industries. This compelling growth underscores the necessity for manufacturers to invest in

cutting-edge machinery that not only enhances productivity but also ensures superior product quality.

The right Glass Edge Polishing Machine can dramatically improve the finishing processes, leading to superior aesthetics and functionality,

ultimately positioning businesses to capture a more significant share of the increasingly competitive global market.

As the saying goes, “Quality is the best business plan,” emphasizing that the path from China to the world relies heavily on exceptional product standards

and technological advancements.

Key Features to Look for in a Top-Notch Glass Edge Polishing Machine

When investing in a glass edge polishing machine, it is crucial to identify key features that ensure high-quality performance and efficiency. One of the most significant aspects is the machine's speed and versatility. According to a report by the Glass Industry Institute, machines that can perform multiple polishing operations at varying speeds can enhance productivity by up to 30%. This adaptability allows manufacturers to cater to diverse client requirements, ranging from thick glass panels to intricately designed edges.

Another essential feature to consider is the machine's

automation capabilities. Modern glass edge polishing machines increasingly leverage advanced technology, including

CNC (Computer Numerical Control) systems, to optimize precision and reduce manual intervention. Research from the International Glass Association indicates that automation can decrease labor costs by as much as

25% while improving the consistency of the finished product. Additionally, machines equipped with robust dust and waste management systems help maintain a clean working environment and comply with safety regulations, further boosting operational efficiency.

Lastly, the

durability and build quality of a glass edge polishing machine are paramount. Machines constructed with high-quality materials can last significantly longer, often exceeding

10 years of reliable service, leading to lower total cost of ownership. Investing in a quality machine not only enhances production capabilities but also provides the longevity needed to withstand the demands of the glass processing industry.

Understanding the Different Types of Glass Edge Polishing Machines Available

When considering an investment in glass edge polishing machines, it's essential to understand the various types available on the market. The primary categories include manual, semi-automatic, and fully automatic machines. According to a recent industry report by Grand View Research, the glass processing equipment market is expected to grow at a CAGR of 5.8% from 2023 to 2030, reflecting a rising demand for efficient and high-quality glass finishing solutions.

Manual machines are often suitable for smaller operations that require precision on a limited scale. They offer flexibility but can be labor-intensive. Semi-automatic machines provide a middle ground, enhancing productivity while still allowing for some operator control. In contrast, fully automatic models are designed for high-volume production environments, significantly improving speed and reducing labor costs.

Tips: When selecting a glass edge polishing machine, consider the specific needs of your operation. Look for machines that offer versatile polishing capabilities and have a reputation for durability. Additionally, evaluate the total cost of ownership, including maintenance and operational costs, to ensure you are making a sound investment that will enhance your production efficiency.

How to Evaluate Potential Suppliers for Quality and Reliability

When investing in a glass edge polishing machine, evaluating potential suppliers is crucial for ensuring quality and reliability. A recent industry report from Smithers states that 68% of manufacturers identify supplier reliability as a top concern affecting production efficiency. Therefore, take time to assess the supplier's track record, including their customer reviews and warranty policies.

One effective way to gauge a supplier's reliability is through direct communication. Ask questions regarding their manufacturing processes, delivery timelines, and after-sales support. Transparency in these areas often indicates a commitment to customer satisfaction. Consider manufacturers that have ISO certifications, as it demonstrates adherence to international quality standards.

When comparing potential suppliers, don’t forget to request samples of their machines. This hands-on experience allows you to evaluate the machine's actual performance and build quality. Implementing a thorough assessment can lead to a more informed purchasing decision, ultimately helping you invest confidently in the best glass edge polishing machine tailored to your needs.

Investment Benefits of Glass Edge Polishing Machines

This bar chart presents the various benefits of investing in the best glass edge polishing machines. The importance level is rated on a scale from 0 to 100, reflecting how each factor contributes to the overall value of the investment.

The Importance of After-Sales Support When Choosing a Glass Polishing Machine

When selecting a glass polishing machine, after-sales support is a critical factor that should not be overlooked. According to a recent industry report by MarketsandMarkets, 70% of manufacturers indicate that effective after-sales service is essential for maintaining operational efficiency and prolonging equipment lifespan. In the glass processing industry where precision matters, the availability of timely support and resources can mitigate downtime, ultimately impacting production schedules and profitability.

Moreover, a study by Technavio highlights that companies willing to invest in robust after-sales support can see a 20% increase in customer satisfaction and loyalty. This is particularly relevant in the competitive landscape of glass manufacturing, where businesses strive not only for quality products but also for dependable operational processes. Access to trained technicians, readily available spare parts, and comprehensive maintenance programs can prevent small issues from escalating into costly disruptions. As manufacturers explore options for glass edge polishing machines, prioritizing after-sales support can significantly enhance both the machine's performance and the overall return on investment.

Practical Tips for Maintaining Your Glass Edge Polishing Equipment

When it comes to maintaining your glass edge polishing equipment, regular upkeep is crucial for ensuring optimal performance and longevity. One practical tip is to establish a routine cleaning schedule. After each use, make it a habit to remove any glass particles, dust, or polish residue from the machine. This not only improves the machine's efficiency but also prevents build-up that could cause wear over time. A clean machine operates better and requires fewer repairs, saving you time and money in the long run.

Another essential aspect of maintenance is regularly checking the machine's components for wear and tear. Inspect the polishing pads and belts closely, as they can significantly affect the quality of the finished product. Look for signs of damage or irregular wear, and replace them as necessary. Additionally, ensuring that the machine is properly lubricated can prevent friction and overheating, ultimately extending the life of your glass edge polishing equipment. By adhering to these practical tips, you'll ensure consistent results and maximize your investment in a high-quality polishing machine.

7 Unbeatable Reasons to Invest in the Best Glass Edge Polishing Machine - Practical Tips for Maintaining Your Glass Edge Polishing Equipment

| Reason |

Benefit |

Maintenance Tips |

| High Efficiency |

Increases production speed, saving time and labor costs. |

Regularly clean the machine to ensure optimal performance. |

| Consistent Quality |

Delivers uniform finishes on glass edges, improving product quality. |

Check and replace worn pads or belts frequently. |

| User-Friendly |

Simple controls that minimize training time for operators. |

Provide user manuals and regular training sessions for staff. |

| Durability |

Built from high-quality materials, ensuring long lifespan and reliability. |

Conduct periodic inspections for wear and tear on components. |

| Cost-Effective |

Reduces waste and energy consumption, lowering overall production costs. |

Monitor energy usage and seek to optimize efficiency. |

| Enhances Safety |

Systems designed with safety features to protect operators. |

Ensure safety guards are in place and functional. |

| Versatility |

Can handle various glass types and thicknesses. |

Regularly test different glass types to identify best settings. |

Home

About Us

Products

UPVC PVC Window Machine

Aluminum Window Machine

Glass Cutting Machine

Glass Edging Machine

Insulating Glass Machine

Glass lifting machine

Glass Washing Machine

Glass Laminating Machine

Glass Sandblasting Machine

Glass Drilling Machine

CNC Glass Working Center

CNC Non-Metal Cutting Machine

The Other Glass Machinery

Application

Download

News

Contact Us