Ultimate Guide to Mastering Cnc Glass Cutting Machine Techniques

In today's fast-paced manufacturing landscape, the CNC Glass Cutting Machine has emerged as an essential tool for businesses seeking precision and efficiency in their operations. This ultimate guide aims to delve into mastering the techniques of CNC glass cutting, showcasing a variety of industry applications where this technology has transformed production processes. From architectural glass installations to intricate decorative pieces, we will explore real-world case studies that demonstrate the machine's versatility and effectiveness. Additionally, we will provide insightful data and key reasons why investing in a CNC Glass Cutting Machine can significantly enhance productivity, reduce waste, and ultimately lead to greater profitability. Whether you are a seasoned professional or a newcomer to the industry, this guide will equip you with the knowledge and skills needed to excel in the realm of CNC glass cutting.

Understanding CNC Glass Cutting: Basics and Importance in Modern Manufacturing

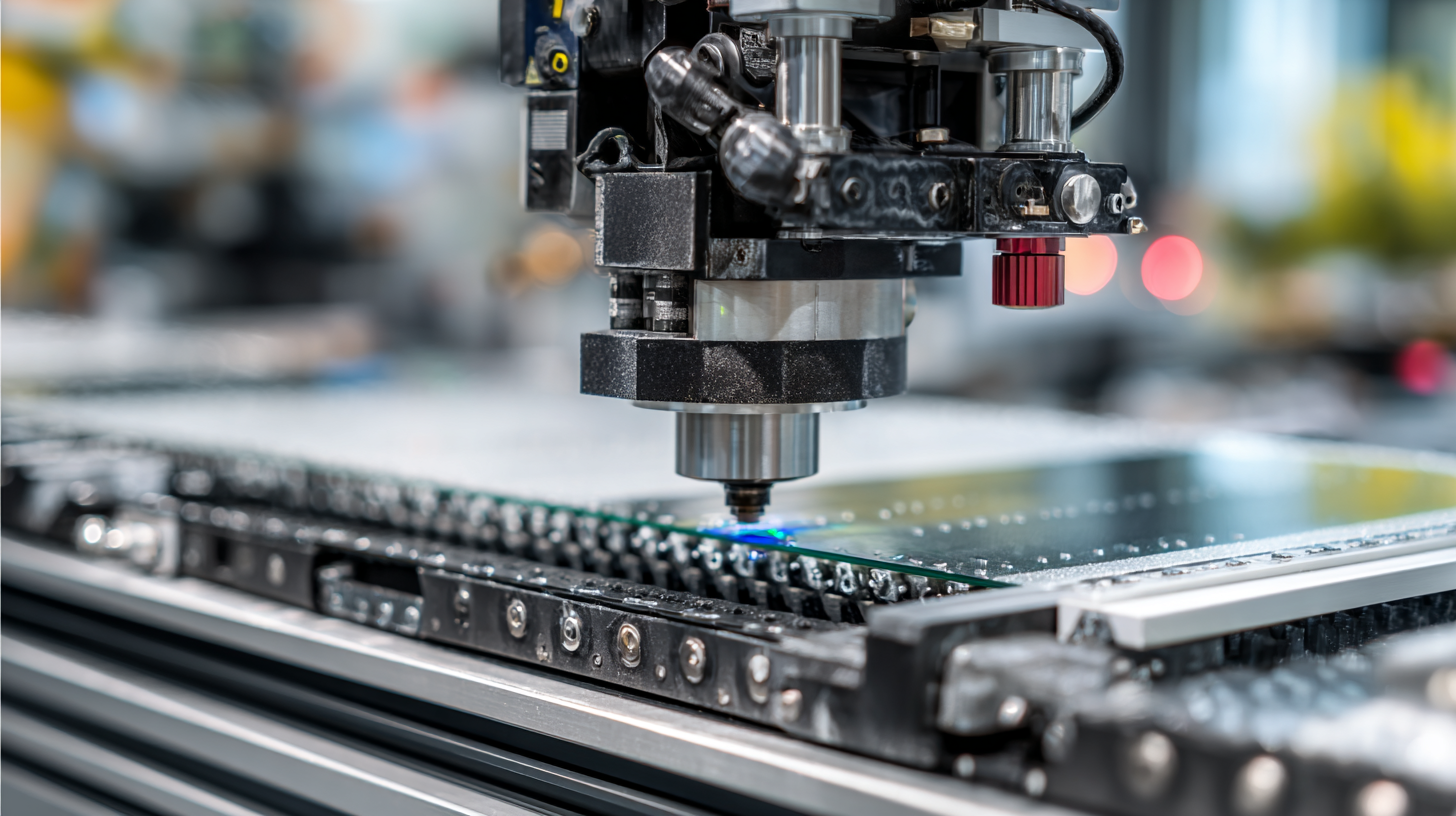

CNC glass cutting technology has revolutionized modern manufacturing, providing precision and efficiency that manual methods simply cannot match. Understanding the basics of CNC glass cutting is essential for businesses looking to enhance their production capabilities. This technique allows for intricate designs and shapes to be achieved with minimal waste, making it a vital tool in industries ranging from architecture to automotive design.

To master CNC glass cutting, it's crucial to familiarize yourself with the machinery and software involved. One valuable tip is to invest time in learning the specific requirements of different glass types, as each kind behaves differently during the cutting process. Additionally, regularly maintaining your CNC machine can significantly improve its performance and longevity. Keeping blades sharp and calibrating the equipment ensures clean cuts and reduces the risk of breakage.

Another important aspect is understanding the importance of programming. Utilize advanced software features for designing layouts that minimize excess material. This not only boosts efficiency but also saves costs in the long run. Lastly, consider training your team on the best practices for operating CNC machines, as skilled operators are key to maximizing the potential of this powerful technology.

Ultimate Guide to Mastering CNC Glass Cutting Machine Techniques

| Technique |

Description |

Applications |

Benefits |

| Water Jet Cutting |

Utilizes high-pressure water mixed with abrasives to cut glass. |

Architectural glass, automotive glass. |

Precision cutting with minimal edge chipping. |

| Laser Cutting |

Uses focused laser beams for extreme precision in cutting glass. |

Decorative glass, custom designs. |

High speed and excellent edge quality. |

| Diamond Blade Cutting |

Employs diamond-coated blades for cutting various thicknesses of glass. |

Flat glass trimming, glass tiles. |

Durability and prolonged tool life. |

| CNC Etching |

Involves engraving detailed designs onto glass surfaces using CNC technology. |

Personalized gifts, awards, and signage. |

Creates intricate designs with precision. |

Key Techniques for Precision Cutting with CNC Glass Machines

CNC glass cutting machines have revolutionized the glass fabrication industry, offering unparalleled precision and efficiency. According to a report by Research and Markets, the global CNC machine market is expected to grow at a CAGR of 7.5% from 2021 to 2026, driven by advancements in automation and system integration technologies. Mastering key techniques in CNC glass cutting not only enhances accuracy but also boosts production capabilities, making it essential for operators and businesses alike.

One of the most critical techniques for precision cutting is the calibration of the CNC machine. Regular calibration ensures that the machine maintains its accuracy, which can significantly reduce waste and errors. Reports from the Glass Industry Association indicate that companies that implement strict calibration protocols can decrease their production costs by up to 15%. Another vital technique is the choice of cutting tools; utilizing diamond-tipped bits tailored for glass can dramatically enhance cutting quality and longevity, resulting in smoother finishes and reduced chipping during the cutting process. These techniques collectively contribute to achieving the highest standards of precision and efficiency in glass cutting operations.

Exploring Industry 2025 Trends and Innovations in CNC Glass Cutting

As we look towards 2025, the CNC glass cutting industry is on the brink of significant transformation driven by innovative technologies and an ever-evolving market landscape. Industry leaders are increasingly integrating automation and artificial intelligence into their CNC systems, enhancing precision and efficiency. These advancements allow for more complex designs to be executed with ease, catering to a growing demand for personalized glass products in sectors ranging from architecture to automotive.

Moreover, sustainability is rapidly becoming a cornerstone of the glass manufacturing process. Innovations in CNC technology are not only focused on improving production capabilities but also on minimizing waste and energy consumption. Manufacturers are adopting eco-friendly materials and recycling practices, positioning themselves as responsible players in the industry. As we approach 2025, staying abreast of these trends will be crucial for companies aiming to thrive in a competitive environment while also appealing to environmentally conscious consumers.

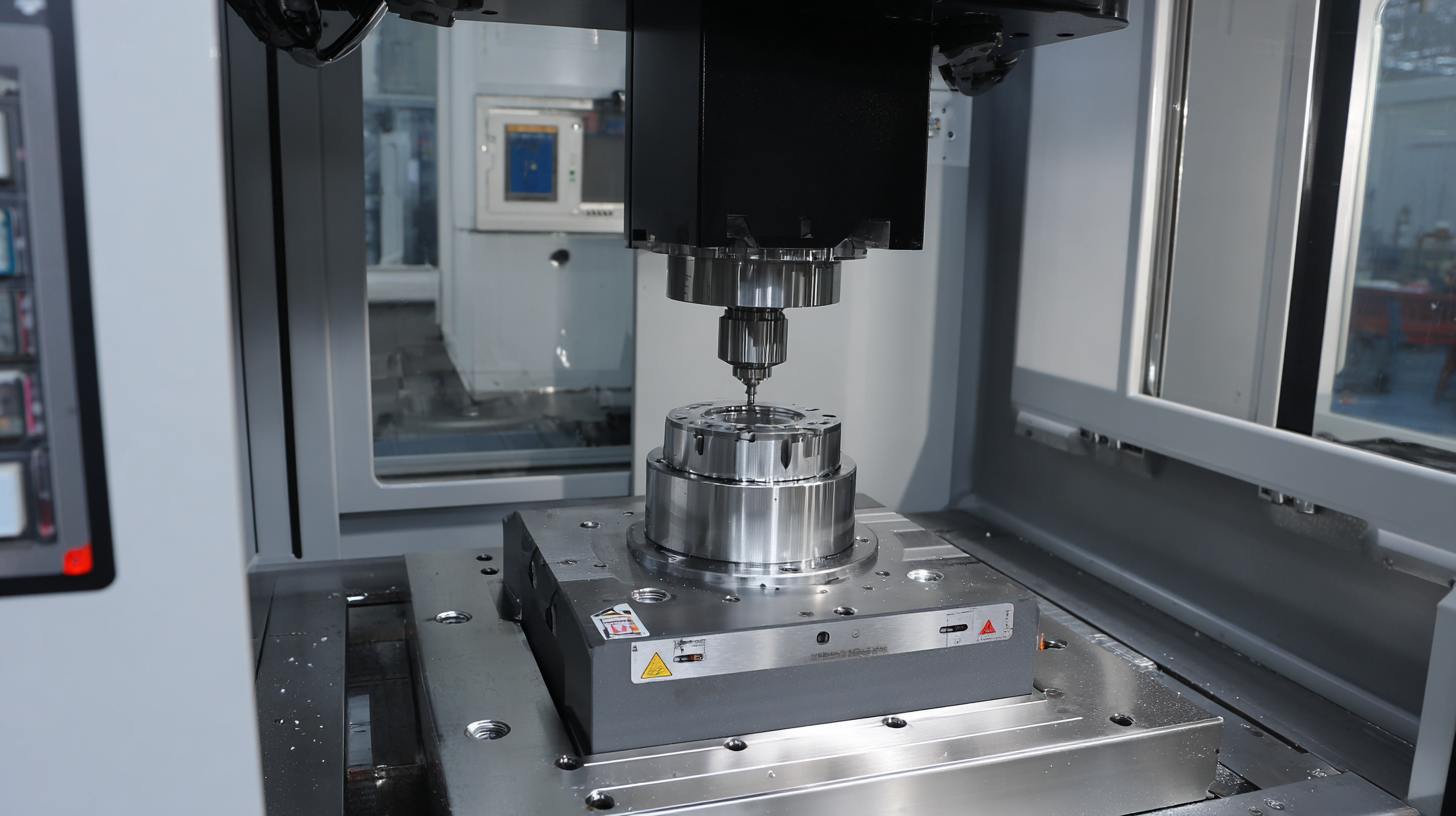

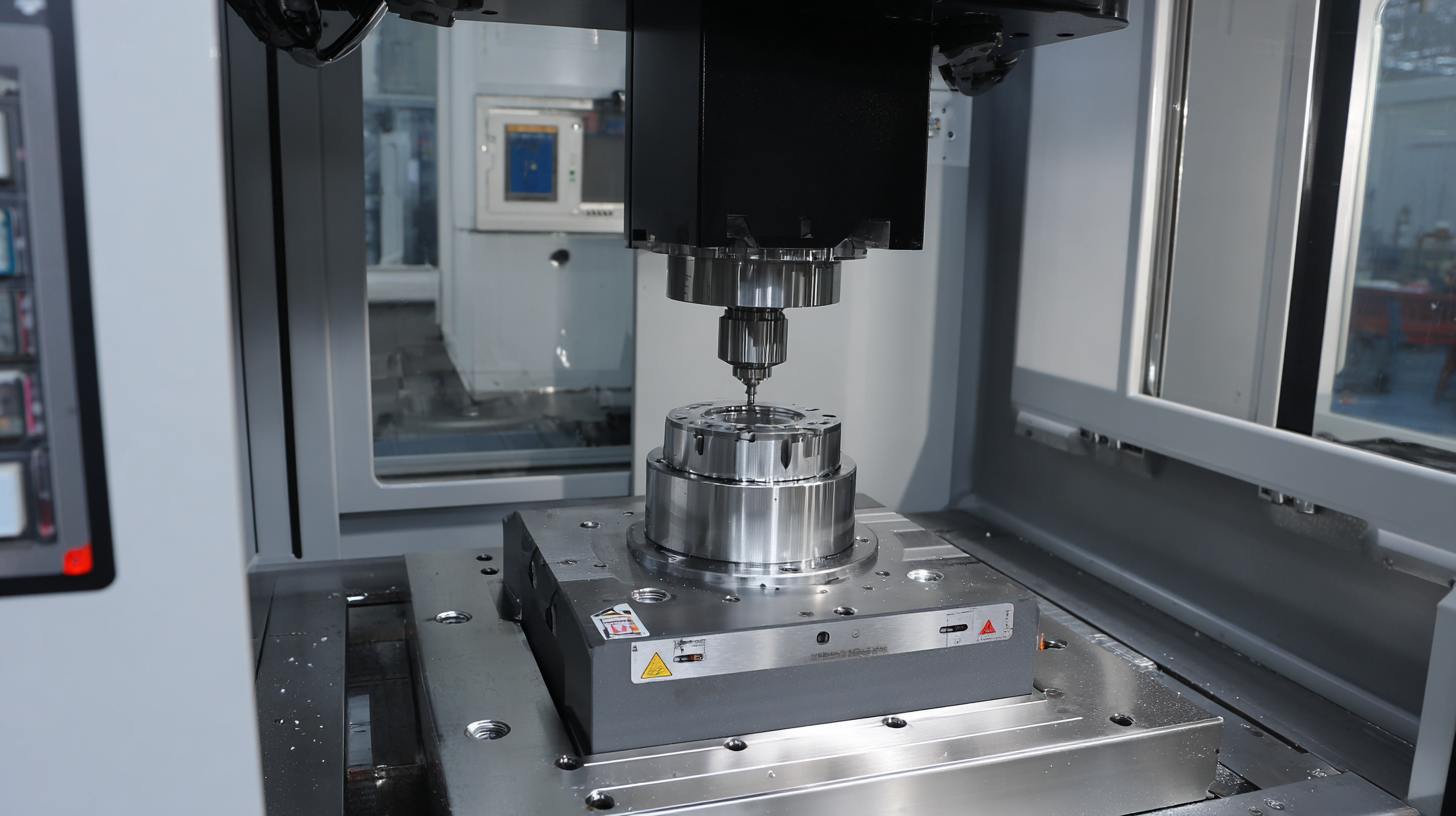

Expert Tips for Optimizing CNC Machine Settings for Different Glass Types

When it comes to optimizing CNC machine settings for different glass types, understanding the specific attributes of each glass variant is essential. For example, float glass, which is one of the most commonly used types, requires lower cutting speeds and higher feed rates to prevent thermal stress and chipping. Proper spindle speed settings also play a crucial role; too high a speed can lead to overheating, while too low can increase cutting time, hindering productivity.

In contrast, when working with more delicate materials like laminated glass, adjustments are necessary to ensure precision. Lowering the feed rates and carefully managing the cutting depth can help maintain the integrity of the layers within the glass. Using appropriate bit types and coating can significantly influence the quality of the cut and the longevity of the tools. Additionally, incorporating cooling systems to dissipate heat during the cutting process can further enhance the performance and durability of the CNC machine, ensuring optimal results across various glass types.

Common Challenges in CNC Glass Cutting and How to Overcome Them

CNC glass cutting can present a range of challenges, especially when dealing with complex materials like glass-fiber-reinforced plastics. One of the primary difficulties is managing the inherent brittleness of glass, which can lead to chipping or cracking during cutting. To tackle this issue, operators can optimize cutting speeds and feeds, ensuring that they employ the right tools and technology suitable for the material. Additionally, utilizing proper coolant and lubrication not only helps to reduce friction but also minimizes residual thermal stress, promoting a cleaner cut.

Another common challenge is achieving precision in intricate designs. The intricacies involved in CNC glass cutting necessitate advanced programming and machine calibration. Operators should invest time in simulation software to visualize the cutting path before executing on the actual material. Moreover, consistently maintaining the CNC machine and keeping tools sharp are crucial for preserving accuracy. With strategic planning and care, shops can effectively overcome these obstacles, ensuring high-quality results in their CNC glass cutting projects.

Home

About Us

Products

UPVC PVC Window Machine

Aluminum Window Machine

Glass Cutting Machine

Glass Edging Machine

Insulating Glass Machine

Glass lifting machine

Glass Washing Machine

Glass Laminating Machine

Glass Sandblasting Machine

Glass Drilling Machine

CNC Glass Working Center

CNC Non-Metal Cutting Machine

The Other Glass Machinery

Application

Download

News

Contact Us