Unlocking Precision: The Ultimate Guide to Manual Glass Cutting Machines and Their Applications

The demand for precision in glass cutting has reached unprecedented heights, highlighting the significance of the Manual Glass Cutting Machine in various industries. According to a recent report by the Global Glass Industry Analysis, the market is anticipated to grow at a CAGR of 4.6% from 2021 to 2026, driven by advancements in fabrication technologies and increasing applications in construction and automotive sectors. Manual glass cutting machines, known for their ability to deliver intricate cuts with minimal waste, become indispensable tools in this evolving landscape. Their adaptability to various glass types, including tempered and laminated glass, showcases their versatility and reliability, catering to diverse customer needs. As the industry continues to embrace automation, understanding the unique advantages of manual systems is essential for ensuring optimal outcomes in precision glass cutting.

Understanding Manual Glass Cutting Machines: Types and Features

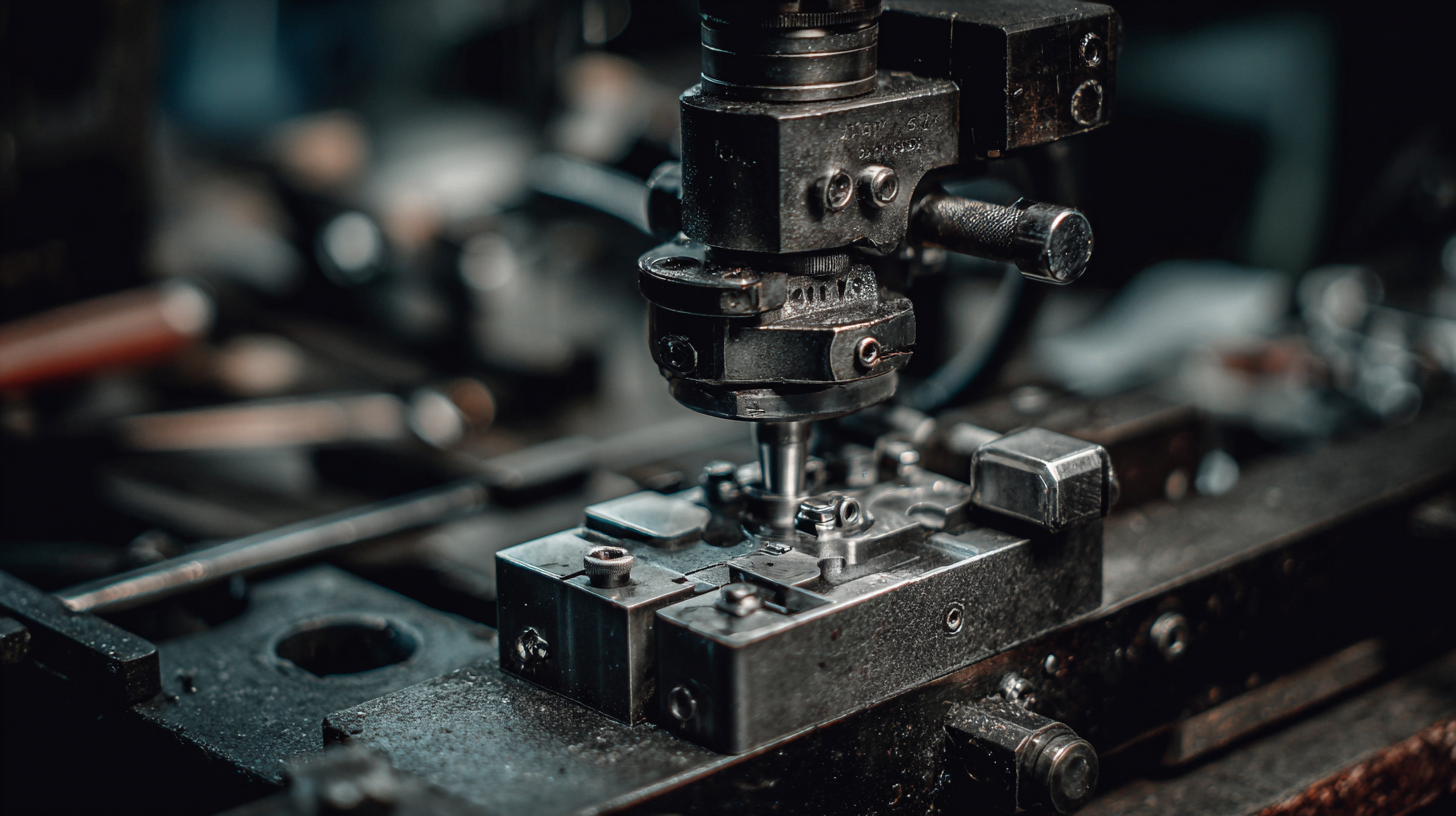

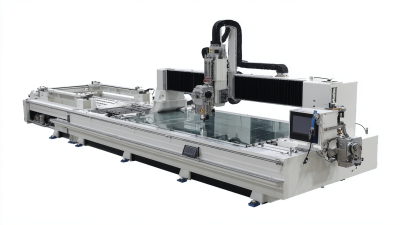

Manual glass cutting machines are essential tools in the glass fabrication industry, enabling precise and efficient cutting for a variety of applications. These machines come in various types, including handheld cutters, straight-line cutters, and score-and-break models, each designed to meet specific cutting needs. According to a report by Market Research Future, the global glass processing market is anticipated to reach USD 60 billion by 2027, further highlighting the increasing demand for effective glass cutting solutions.

Handheld cutters are favored for their portability and versatility, perfect for small-scale projects and custom cuts. On the other hand, straight-line cutters are designed for larger sheets of glass, providing straight, even cuts that are crucial in large-scale fabrication settings. Features such as adjustable cutting depths and specialized wheels enhance precision, allowing manufacturers to achieve clean edges that meet industry standards. The integration of advanced materials and ergonomic designs in these machines has been shown to improve user efficiency by up to 30%, according to industry reports, making them invaluable in modern glass production processes.

Key Applications of Manual Glass Cutting Machines in Different Industries

Manual glass cutting machines are versatile tools widely used across various industries, including construction, automotive, and art. In the construction sector, these machines allow for precise cutting of glass panels, ensuring a perfect fit in windows and facades. Their portability makes them ideal for on-site applications, where quick modifications or custom cuts are often needed. Similarly, in the automotive industry, glass cutting machines are crucial for reshaping windshields and side windows, providing a perfect replacement that adheres to safety standards.

In the art world, manual glass cutting machines facilitate the creation of intricate designs and stained glass projects. Artists can explore their creativity while maintaining control over the dimensions and angles of the glass pieces. The ability to make customized cuts opens up new possibilities for unique artwork, sculptures, and decorative items.

Tips: Always ensure to wear protective gear when operating manual glass cutting machines, as safety should be a priority. Additionally, using a quality cutting tool can significantly improve accuracy and reduce the chances of glass breakage. Regular maintenance of the machine will also prolong its lifespan and enhance its cutting performance.

Comparative Analysis of Manual vs. Automated Glass Cutting Techniques

Manual glass cutting techniques have long been a staple in industries ranging from construction to art. According to a report by IBISWorld, the glass manufacturing industry is projected to grow by 4.5% annually between 2021 and 2026, partially driven by the craftsmanship and precision offered by manual cutting methods. These machines allow skilled operators to make intricate cuts and adjustments, catering to bespoke projects where customization is key. Such precision is especially crucial in high-end applications, where the quality of the cut can significantly affect the final product's aesthetics and structural integrity.

On the other hand, automated glass cutting machines bring speed and consistency to the production process. Data from the Glass Association indicates that automated cutting can increase production rates by up to 30% while minimizing material waste due to precise measurements and repeatability. However, the initial investment in automation technology can be substantial, which may deter small businesses from making the switch. Ultimately, the choice between manual and automated techniques hinges on project specifications, company size, and budget, making the comparative analysis a vital consideration for industry players seeking to optimize their operations.

Safety Standards and Best Practices for Using Manual Glass Cutting Machines

When using manual glass cutting machines, adhering to safety standards is paramount to prevent accidents and injuries. Proper personal protective equipment (PPE) is essential; this includes safety goggles, gloves, and steel-toed boots. Ensuring a clean and organized workspace minimizes the risk of slips and falls, while also keeping tools and materials within easy reach. Familiarity with the equipment is crucial, so operators should read the manufacturer’s instructions thoroughly before use.

Best practices involve not only personal safety but also proper technique when handling glass. It’s important to score the glass correctly using steady pressure to avoid shattering. Operators should always cut away from their bodies and maintain a firm grip on the glass piece. Regular maintenance of the cutting tools, including replacing dull blades, can improve both performance and safety. Furthermore, using a suitable cutting surface aids in stabilizing the glass, contributing to both precision and safety during the cutting process. By following these guidelines, operators can enhance their productivity while ensuring a safer working environment.

Market Trends and Future Developments in Manual Glass Cutting Technology

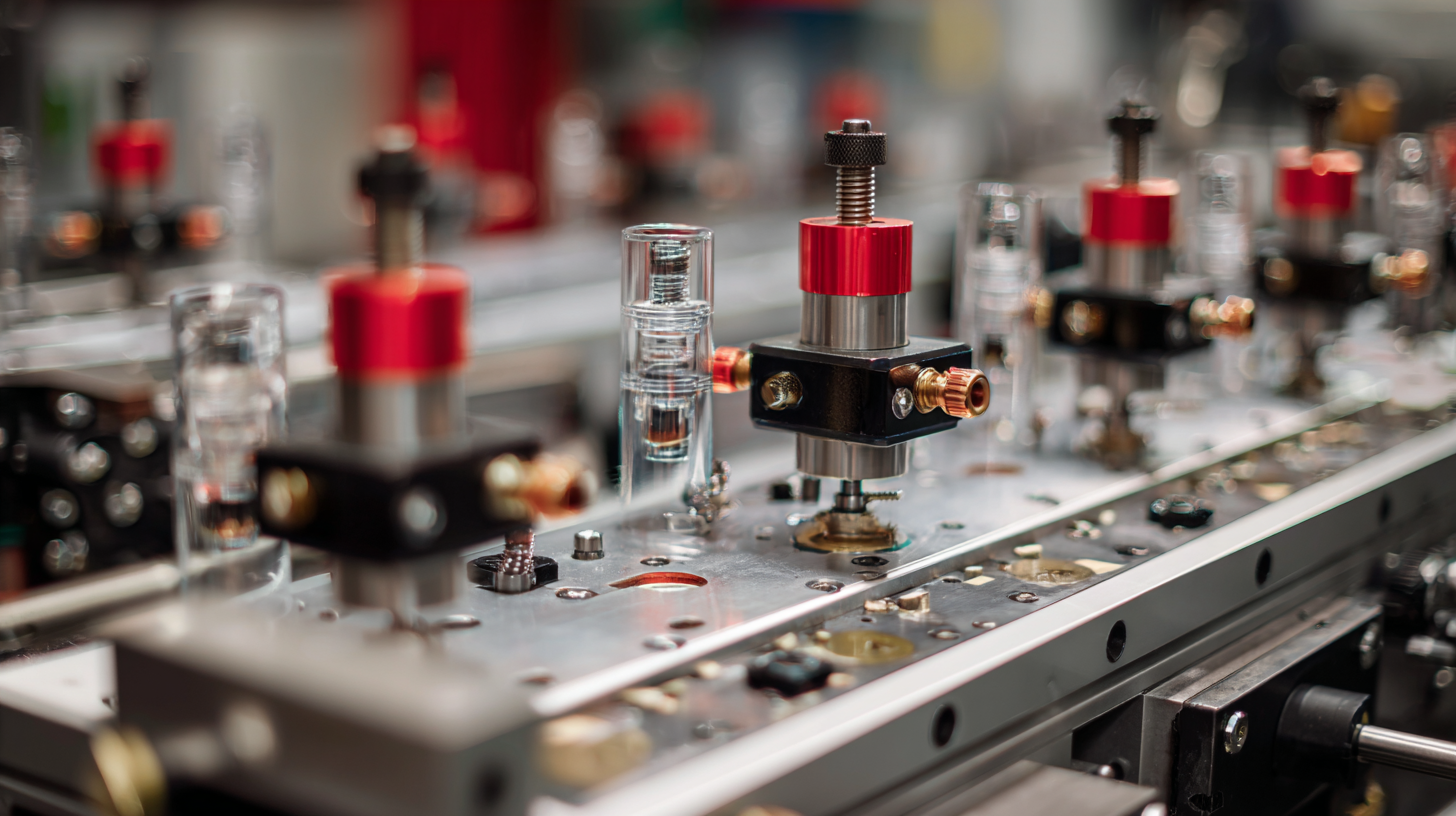

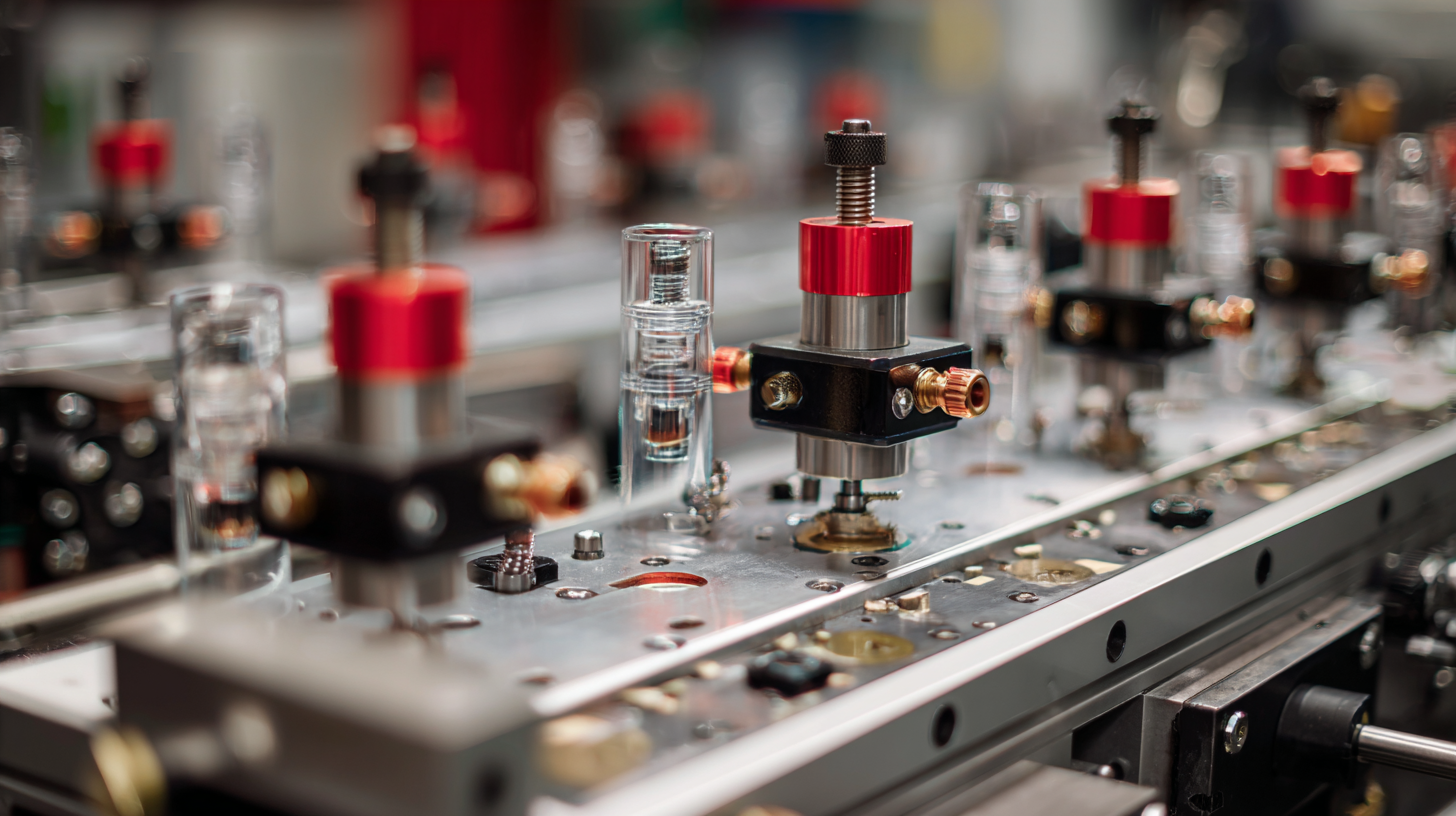

The manual glass cutting machine market has seen significant advancements driven by innovation and evolving consumer needs. According to a report by Market Research Future, the global manual glass cutting machines market is projected to grow at a CAGR of 4.5% over the next five years, fueled by increased demand in the construction and automotive sectors. As industries shift towards more sustainable practices, the introduction of energy-efficient cutting technologies is becoming a top priority. Companies are investing in R&D to enhance precision and reduce waste, which is key for both operational efficiency and environmental responsibility.

Furthermore, smart technology integration in manual glass cutting machines plays a crucial role in this evolving landscape. A report from Grand View Research highlights that by 2025, the adoption of automated features in manual glass cutting will rise, driven by the need for better accuracy and productivity. This shift not only allows for improved performance but also caters to the growing trend of customization, where manufacturers can offer tailored solutions to meet diverse customer demands. The adoption of advanced materials and smart fabrication techniques will undoubtedly shape the future of manual glass cutting technology, paving the way for more innovative applications across various industries.

Unlocking Precision: The Ultimate Guide to Manual Glass Cutting Machines and Their Applications

| Feature |

Specification |

Application |

Market Trends |

Future Developments |

| Cutting Mechanism |

Manual scoring and snapping |

Artisan glassworks |

Increasing demand in DIY renovations |

Integration with advanced materials |

| Blade Material |

Diamond or tungsten carbide |

Glass arts and crafts |

Growth in custom glass products |

Development of more durable blades |

| Portability |

Lightweight and compact |

On-site installations |

Rise of mobile glass-cutting services |

Adoption of smart technology in tools |

| Cutting Thickness |

Up to 10mm |

Home improvement projects |

Increased usage in architecture and design |

Research on thinner glass cutting capabilities |

Home

About Us

Products

UPVC PVC Window Machine

Aluminum Window Machine

Glass Cutting Machine

Glass Edging Machine

Insulating Glass Machine

Glass lifting machine

Glass Washing Machine

Glass Laminating Machine

Glass Sandblasting Machine

Glass Drilling Machine

CNC Glass Working Center

CNC Non-Metal Cutting Machine

The Other Glass Machinery

Application

Download

News

Contact Us