Exploring Types of Glass Shape Edging Machines Features Applications and How to Choose the Best One

In the rapidly evolving world of glass processing technology, the Glass Shape Edging Machine has emerged as a critical tool for manufacturers and artisans alike. As we approach 2025, understanding the various types of these machines, their unique features, and diverse applications becomes essential for anyone in the industry. This blog will delve into the significant advancements and trends expected in the field of glass shape edging, providing readers with a comprehensive guide on how to select the best machine tailored to their specific needs. Whether you are looking to enhance precision in your production or explore innovative designs, this exploration will equip you with the necessary insights to make informed decisions in the selection of a Glass Shape Edging Machine.

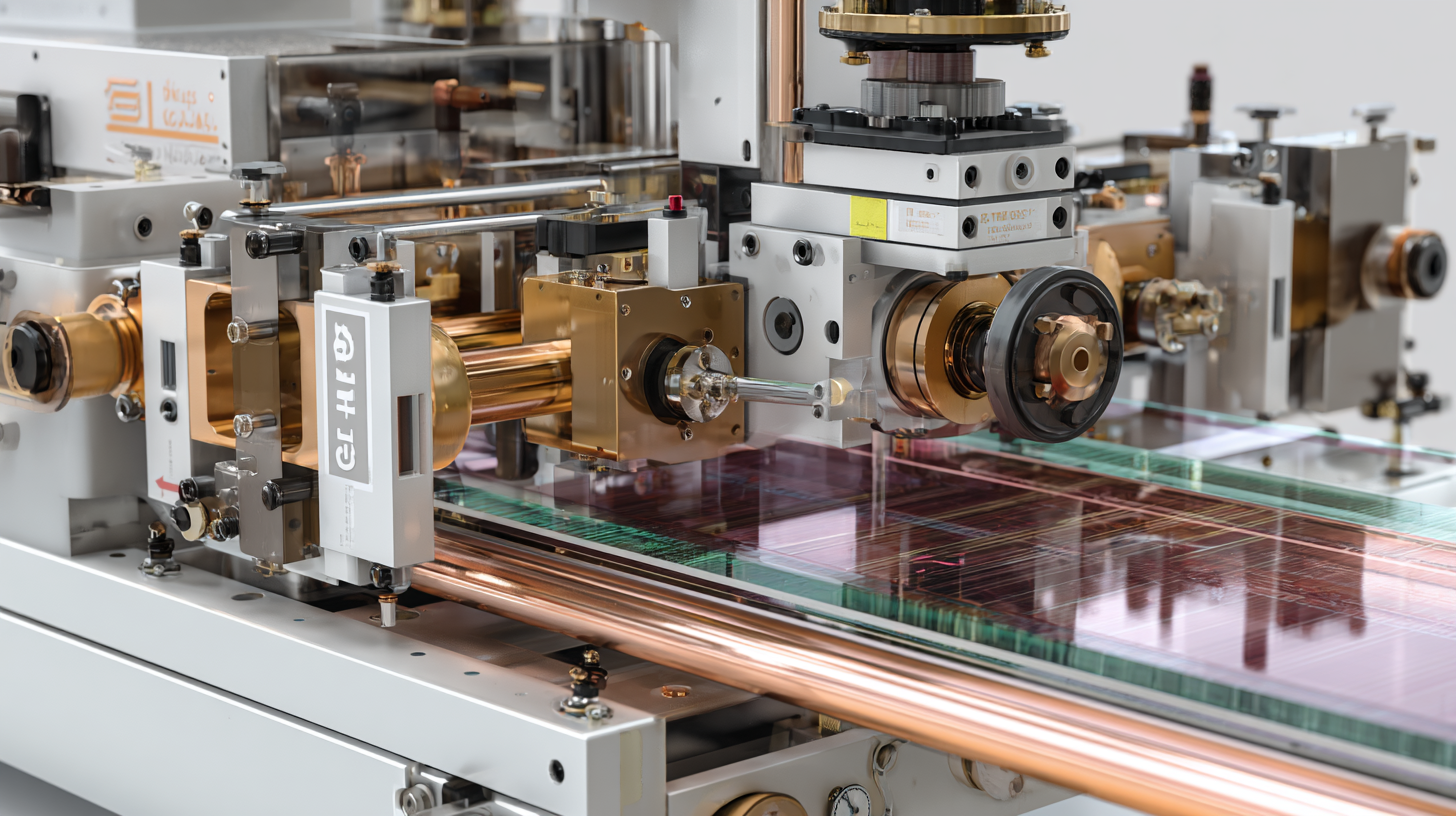

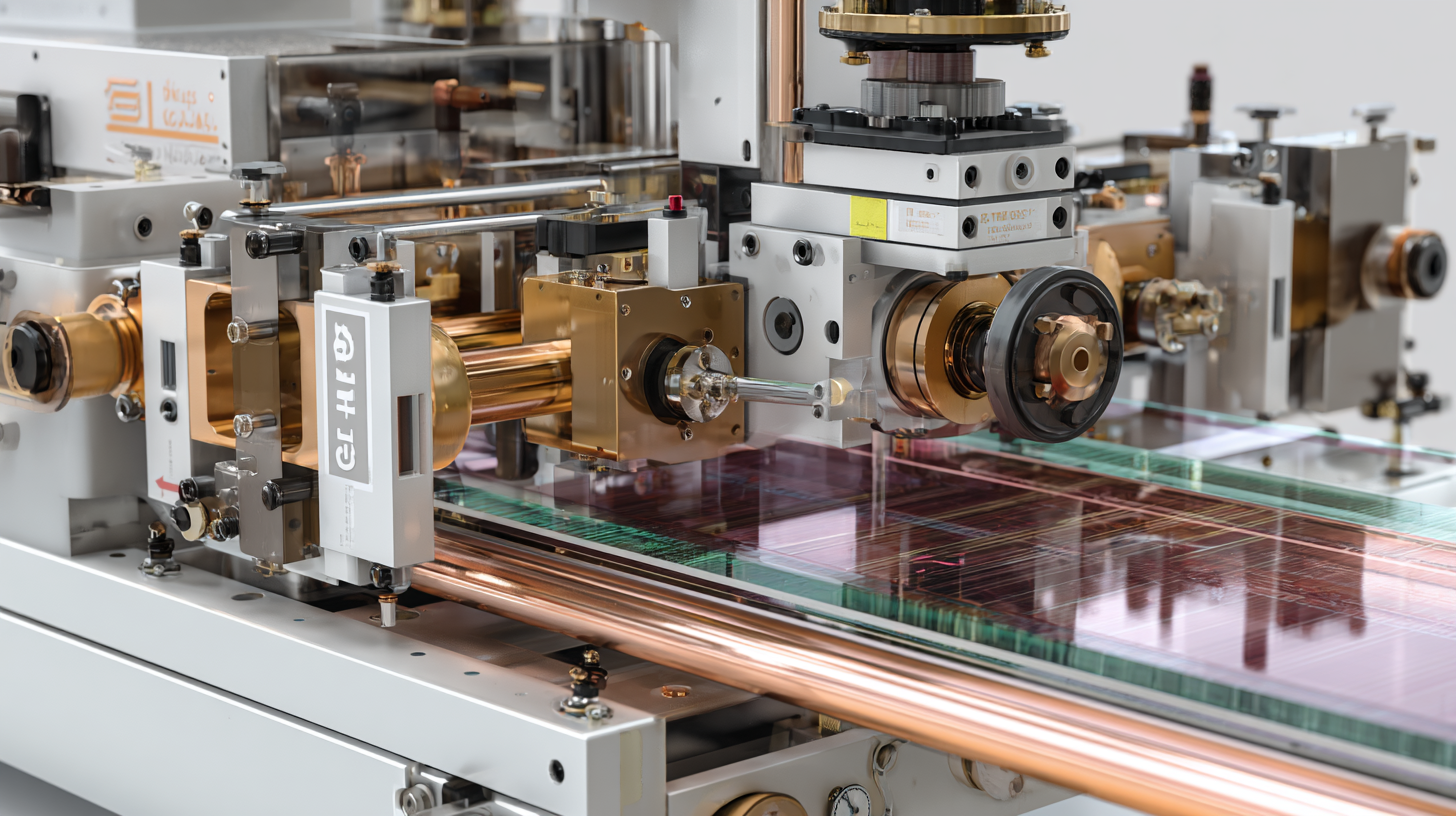

Types of Glass Shape Edging Machines and Their Unique Features

When exploring the various types of glass shape edging machines, it's essential to understand their unique features and applications. These machines are designed to improve the optical quality and strength of glass edges significantly, especially after grinding and polishing processes. Recent studies highlight the importance of using specific grinding and polishing cup wheels to achieve higher precision. For instance, the right wheel can enhance surface smoothness, which is crucial for avoiding defects that may arise during the cutting phase. The advancements in polishing technology can lead to a reduction in edge chipping, thus ensuring the longevity of glass products in various applications.

Another innovative development in the realm of glass shaping is the integration of machine learning to predict the geometric characteristics of highly bent glass. This methodology aids manufacturers in understanding how glass reacts to stress and the bending process. The application of machine learning not only optimizes the shape prediction of panels but also aligns with the industry's increasing emphasis on stronger, more resilient glass products. Additionally, research indicates that conventional edge-finishing techniques for annealed glass might not adequately meet the demands of the building industry, advocating for advanced finishing methods to improve safety and structural integrity. These findings underscore the necessity of choosing the right glass edging machine that can handle the evolving needs of construction and design.

Key Applications for Glass Shape Edging Machines in Various Industries

Glass shape edging machines play a crucial role across various industries by providing precision and quality finishes to glass products. In the architecture and construction sector, these machines are essential for creating aesthetically pleasing glass panels and facades. They offer the capability to produce unique shapes and edge styles that enhance both functionality and visual appeal, meeting the demands of modern design trends. Moreover, with the growing emphasis on energy efficiency, customized glass edges can improve the performance of energy-efficient windows, making these machines indispensable in the construction process.

Glass shape edging machines play a crucial role across various industries by providing precision and quality finishes to glass products. In the architecture and construction sector, these machines are essential for creating aesthetically pleasing glass panels and facades. They offer the capability to produce unique shapes and edge styles that enhance both functionality and visual appeal, meeting the demands of modern design trends. Moreover, with the growing emphasis on energy efficiency, customized glass edges can improve the performance of energy-efficient windows, making these machines indispensable in the construction process.

In the furniture and interior design industries, glass shape edging machines are utilized for crafting elegant table tops, cabinets, and decorative elements. The ability to create intricate designs and smooth edges adds a sophisticated touch to furniture pieces, as well as ensuring safety and durability. Additionally, the automotive industry benefits from these machines by producing glass components like windshields and windows, which require precise edging for strength and clarity. By understanding the specific applications within these sectors, businesses can select the right glass shape edging machine that meets their production needs, ultimately enhancing their product quality and market competitiveness.

Factors to Consider When Choosing a Glass Shape Edging Machine

When selecting a glass shape edging machine, there are several critical factors to consider to ensure optimal performance and application.

First and foremost, the type of glass being processed plays a pivotal role. For instance, reports from the Glass Association state that different glass materials, such as tempered or laminated glass, may require specialized edging techniques, impacting the choice of machine. Additionally, understanding the thickness range of the glass is crucial, as this can affect the options available.

Machines designed for thicker glass, for example, tend to be more robust and may come equipped with advanced features to handle the increased workload effectively.

Another significant factor is the machine's technological capabilities. According to a recent industry survey, approximately 65% of glass manufacturers reported that automation features enhance productivity and reduce labor costs. Machines with advanced CNC (Computer Numerical Control) systems offer precision and consistency, allowing for intricate designs with minimal human intervention. Furthermore, consider the machine's maintenance and support services, as ongoing service and spare parts availability can greatly affect long-term operational efficiency.

In conclusion, choosing the right glass shape edging machine involves evaluating the type of glass, technological features, and reliable support to ensure that the investment meets the specific needs of your production line.

Common Problems Faced with Different Types of Glass Edging Machines

When it comes to glass edging machines, users often encounter specific challenges that vary across different types. One common issue is inconsistent edge quality, which can result from variations in speed or pressure settings. Manual machines, while cost-effective, may struggle with precision, leading to rough or uneven edges. On the other hand, automatic machines, though more expensive, can provide a more consistent result if properly calibrated. Neglecting proper maintenance can exacerbate these issues, resulting in decreased efficiency and increased downtime.

Another frequent problem is the machine's adaptability to different glass shapes and thicknesses. Many machines are designed for a specific range, and attempting to work outside of these parameters can lead to poor performance or even damage to the glass. Users should pay close attention to machine specifications and features when selecting a model. Depending on the intended application, it may be beneficial to invest in machines that offer adjustable settings to accommodate various glass types, ensuring versatility in production without sacrificing quality.

Exploring Types of Glass Shape Edging Machines Features Applications and How to Choose the Best One - Common Problems Faced with Different Types of Glass Edging Machines

| Type of Machine |

Features |

Applications |

Common Problems |

| Straight Line Edging Machine |

Automated feeding, precision grinding, multiple wheel configurations |

Flat glass processing for windows, mirrors, and doors |

Inconsistent edge quality, wheel wear, misalignment |

| CNC Glass Edging Machine |

Computerized control, customizable shapes, high precision |

Complex shapes and patterns in glassware, decorative panels |

Software glitches, high setup time, maintenance complexities |

| Double Sided Edging Machine |

Dual edge processing, high-speed operation, easy loading |

Table tops, shower doors, glass partitions |

Increased wear on double wheels, uneven edge polish |

| Handheld Glass Edging Tool |

Lightweight, portable, manual control for precise work |

Repair and small-scale projects, artistic work |

Requires skill for uniform edges, limited efficiency |

| Water Jet Glass Edging Machine |

Uses high-pressure water for cutting and edging |

Complex designs, detailed glass art, eco-friendly cutting |

High operational costs, maintenance of water jet systems |

Maintenance Tips to Ensure Optimal Performance of Edging Machines

Maintaining glass shape edging machines is crucial for ensuring their optimal performance and extending their longevity. Regular maintenance checks should be scheduled to inspect key components such as grinding wheels, motors, and water delivery systems. Keeping these parts clean and free from debris not only enhances the machine’s efficiency but also minimizes the risk of costly repairs. Additionally, routine lubrication of moving parts can prevent wear and tear, allowing the machine to operate smoothly.

Another essential aspect of maintenance is monitoring the machine’s precision settings. Over time, even minor misalignments can affect the quality of the finished product. Operators should routinely calibrate the machines to ensure they are functioning as intended. Furthermore, investing in high-quality replacement parts will lead to better performance and result in more consistent glass edges. By adhering to these maintenance tips, operators can ensure their edging machines perform at their best while producing high-quality results.

Types of Glass Shape Edging Machines and Their Applications

Home

About Us

Products

UPVC PVC Window Machine

Aluminum Window Machine

Glass Cutting Machine

Glass Edging Machine

Insulating Glass Machine

Glass lifting machine

Glass Washing Machine

Glass Laminating Machine

Glass Sandblasting Machine

Glass Drilling Machine

CNC Glass Working Center

CNC Non-Metal Cutting Machine

The Other Glass Machinery

Application

Download

News

Contact Us

Glass shape edging machines play a crucial role across various industries by providing precision and quality finishes to glass products. In the architecture and construction sector, these machines are essential for creating aesthetically pleasing glass panels and facades. They offer the capability to produce unique shapes and edge styles that enhance both functionality and visual appeal, meeting the demands of modern design trends. Moreover, with the growing emphasis on

Glass shape edging machines play a crucial role across various industries by providing precision and quality finishes to glass products. In the architecture and construction sector, these machines are essential for creating aesthetically pleasing glass panels and facades. They offer the capability to produce unique shapes and edge styles that enhance both functionality and visual appeal, meeting the demands of modern design trends. Moreover, with the growing emphasis on