Top 10 Glass Shape Beveling Machines for Perfect Edge Finishing

In the rapidly evolving world of glass processing, achieving impeccable edge finishing is crucial for both aesthetic and functional purposes. Among the essential tools for this task, the Glass Shape Beveling Machine stands out as a key player, enabling craftsmen and manufacturers to create precision beveled edges on varying glass shapes. As we approach 2025, advancements in technology and manufacturing processes are set to revolutionize the glass beveling industry, making it imperative for professionals to stay informed about the latest machinery options available on the market.

This article presents a comprehensive overview of the top 10 Glass Shape Beveling Machines that promise to elevate the quality of edge finishing to new heights. By examining the features and capabilities of these machines, we aim to guide readers in selecting the right equipment tailored to their specific needs. Whether you are an established glass fabricator or a newcomer looking to invest in state-of-the-art technology, understanding the latest innovations in beveling machinery will empower you to enhance your production efficiency and product quality. Join us as we explore the best options for achieving perfect edge finishing in the coming years.

Top Innovations in Glass Shape Beveling Technologies for 2025

In 2025, the glass shape beveling industry is witnessing groundbreaking innovations that focus on sustainability and efficiency. With a strong emphasis on decarbonization, the sector is exploring various technologies, such as hydrogen and biogas, aimed at reducing the environmental impact of glass production. Events like the China Glass 2025 showcase cutting-edge advancements in smart manufacturing, highlighting how these innovations are not only enhancing product quality but are also aligning with global sustainability goals.

When considering the selection of beveling machines, it's essential to focus on features that promote efficiency and precision. **Tip:** Look for machines that incorporate advanced automation and AI to streamline operations and improve accuracy in the beveling process. Additionally, evaluate machines offering versatile settings that accommodate various glass shapes, enabling seamless transitions between different projects.

The recent launch of research centers dedicated to glass innovation signifies the industry's commitment to evolving its technological landscape. **Tip:** Stay updated on emerging technologies and market trends by participating in industry events and workshops. Engaging with the community fosters knowledge sharing and can spur new ideas that enhance both product offerings and operational methodologies.

Key Features to Look for in Beveling Machines: Precision and Efficiency

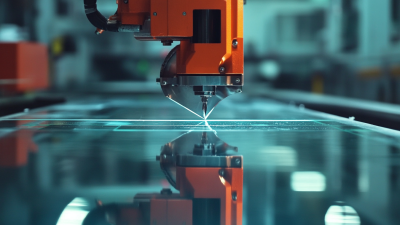

When selecting a beveling machine for glass edge finishing, precision and efficiency should be at the forefront of your consideration. These machines utilize high-quality diamond tools to ensure that bevels are applied with exact angles and smoothness. Look for models that offer adjustable speed settings, allowing you to customize the operation based on the specific type and thickness of glass you're working with. This adaptability ensures a clean and consistent finish, which is crucial for high-end glass projects.

Another key feature to consider is the ease of use, including intuitive controls and quick change mechanisms for tools. A user-friendly design reduces setup time and minimizes operational errors, enhancing overall productivity. It's also beneficial if the machine is equipped with dust collection systems to maintain a clean working environment while safeguarding the quality of your work.

Tips: Always pay attention to the warranty and customer support of the manufacturer. A reliable warranty not only protects your investment but also indicates the manufacturer's confidence in their product's durability. Additionally, seeking out user reviews can provide valuable insights into real-world performance and reliability, helping you make a more informed purchase decision.

Top 10 Glass Shape Beveling Machines Performance Comparison

Market Trends: The Demand for Edge Finishing Solutions in Glass Industry

The glass industry has seen a notable surge in demand for edge finishing solutions, driven by an increasing focus on aesthetics and quality. Recent market analysis indicates that the global market for glass processing equipment, including beveling machines, is projected to grow significantly, reaching an estimated value of several billion dollars by 2025. This trend underscores the importance of investing in advanced technologies to enhance production efficiency and product quality.

As manufacturers strive to meet evolving customer expectations, beveling machines play a crucial role in delivering perfect edge finishing—an essential aspect of glass products used in various applications, from construction to consumer goods. The incorporation of automated solutions streamlines the production process, reduces waste, and minimizes labor costs, making these machines indispensable in modern glass fabrication.

Tips: When selecting a beveling machine, consider features such as speed, precision, and ease of use to ensure optimal performance in your production line. Regular maintenance of these machines can significantly extend their lifespan and improve their efficiency. Finally, staying informed about the latest market trends and technological advancements will help businesses remain competitive in this rapidly evolving industry.

Comparative Analysis of Beveling Machine Models: Performance Metrics

When evaluating glass shape beveling machines, several performance metrics are crucial for determining their effectiveness in achieving perfect edge finishes. Key parameters include motor power, beveling speed, and precision. Higher motor power typically translates to enhanced cutting efficiency, allowing for faster processing of thicker glass materials without compromising quality. Beveling speed, measured in millimeters per minute, directly impacts productivity, especially in high-volume environments. Machines that offer adjustable speed settings provide greater versatility for different glass thicknesses and shapes.

Another important metric is the level of precision achievable by each machine. The finest beveling machines are designed with advanced CNC technology that ensures consistent edge angles and minimal tolerances. This precision is vital for applications where aesthetic and safety standards are paramount. Additionally, the durability and maintenance cost of the machinery should be factored into the analysis, as more robust models often lead to lower operational disruptions over time. Each of these performance metrics plays a significant role in the comparative analysis of beveling machine models, helping businesses choose the most suitable equipment for their specific needs.

Top 10 Glass Shape Beveling Machines for Perfect Edge Finishing

| Model |

Power (kW) |

Max Bevel Angle (°) |

Table Size (mm) |

Weight (kg) |

Price (USD) |

| Model A |

3.0 |

45 |

2000 x 1500 |

850 |

9000 |

| Model B |

4.5 |

30 |

2500 x 2000 |

1050 |

12000 |

| Model C |

2.5 |

60 |

1800 x 1200 |

700 |

7500 |

| Model D |

5.0 |

50 |

3000 x 2500 |

1300 |

15000 |

| Model E |

3.8 |

40 |

2200 x 1800 |

950 |

11000 |

| Model F |

4.0 |

35 |

2600 x 2000 |

1150 |

13000 |

| Model G |

2.8 |

55 |

2100 x 1600 |

820 |

8500 |

| Model H |

6.0 |

25 |

3500 x 3000 |

1500 |

20000 |

| Model I |

3.3 |

55 |

2300 x 1700 |

900 |

9500 |

| Model J |

5.2 |

40 |

2700 x 2200 |

1100 |

14500 |

Future Projections: The Impact of Automation on Glass Beveling Processes

The glass beveling industry is on the brink of transformation due to the increasing adoption of automation technologies. As per a recent industry report by MarketsandMarkets, the glass processing machinery market is projected to reach USD 6.85 billion by 2025, growing at a CAGR of 7.2%. This growth is driven largely by innovations in automated systems, which enhance productivity, reduce labor costs, and improve precision in glass beveling processes. By integrating robotics and AI, manufacturers can achieve not only faster production rates but also consistent quality across products.

To maximize the benefits of automation, it’s crucial for businesses to invest in training their workforce. Employees must be adept at working alongside advanced machines to ensure a seamless operation and maintenance process. Additionally, upgrading existing beveling machines with automation features can significantly improve operational efficiency without the need for a complete overhaul.

Tip: Regularly review the performance metrics of automated machines to identify areas for improvement and adjust workflows accordingly. This will help streamline processes and save costs in the long run. Moreover, consider collaborating with technology providers who specialize in automation solutions for tailored guidance and support.

Home

About Us

Products

UPVC PVC Window Machine

Aluminum Window Machine

Glass Cutting Machine

Glass Edging Machine

Insulating Glass Machine

Glass lifting machine

Glass Washing Machine

Glass Laminating Machine

Glass Sandblasting Machine

Glass Drilling Machine

CNC Glass Working Center

CNC Non-Metal Cutting Machine

The Other Glass Machinery

Application

Download

News

Contact Us