Top 10 Glass Processing Machines: A Comprehensive Guide for Buyers

When it comes to the glass manufacturing industry, the efficiency and quality of production heavily rely on the machinery used. This is where the significance of a Glass Processing Machine comes into play. As one of the pivotal components in glass fabrication, these machines encompass a wide range of functionalities, from cutting and shaping to polishing and finishing. Understanding the different types of glass processing equipment available in the market is crucial for buyers aiming to optimize their production lines.

In this comprehensive guide, we delve into the top ten glass processing machines, providing insights into their features, benefits, and applications. Whether you're a seasoned industry professional or just starting in the glass sector, knowing what to look for in a Glass Processing Machine can significantly influence your operational efficiency and product quality. By highlighting key specifications and considerations, this guide aims to equip potential buyers with the knowledge needed to make informed decisions and invest in machinery that meets their specific requirements.

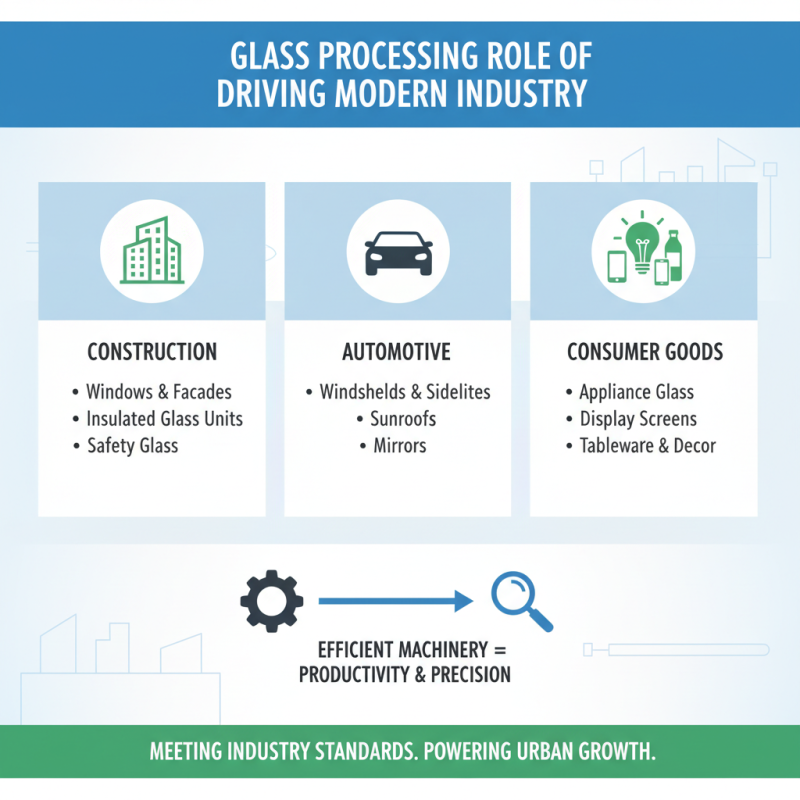

Understanding the Glass Processing Industry and Its Importance

The glass processing industry plays a crucial role in various sectors, including construction, automotive, and consumer goods. As urbanization continues to grow, the demand for glass products like windows, facades, and decorative items has surged. This trend highlights the importance of efficient glass processing machines, which not only enhance productivity but also improve the quality and precision of the final products. Understanding the intricacies of glass processing is essential for buyers who seek machinery capable of meeting specific industry standards.

Moreover, technological advancements have transformed the glass processing landscape, leading to innovations that optimize production capabilities. Techniques such as automated cutting, bending, and polishing have made it possible for manufacturers to achieve intricate designs and high-quality finishes. Buyers must consider factors such as machine durability, cost-effectiveness, and ease of maintenance when selecting equipment. The right machinery investment can significantly influence operational efficiency and the overall competitiveness of businesses in the glass processing market. As the industry continues to evolve, staying informed about the latest processing technologies becomes critical for all stakeholders involved.

Types of Glass Processing Machines and Their Functions

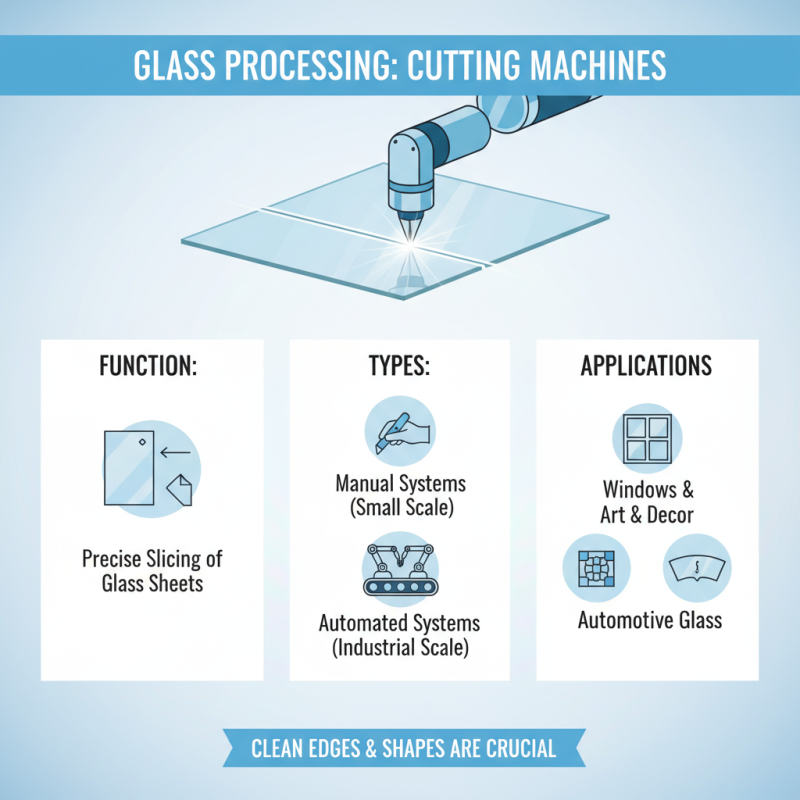

When it comes to glass processing, a variety of machines are utilized to achieve perfect results for different applications. One of the essential types is the cutting machine, designed to slice glass sheets with precision. These machines come in various formats, including manual and automated systems, allowing users to choose based on their production scale. The ability to create clean edges and shapes makes cutting machines crucial for crafting a diverse range of glass products, from windows to intricate art pieces.

Another vital category is the grinding machine, which is used to smooth the edges and surfaces of cut glass. These machines can handle different materials, providing versatility in glass finishing. Grinding machines often come with various attachments, enabling operators to work on different glass thicknesses and achieve specific finishes, whether for aesthetic appeal or safety purposes. Additionally, drilling machines are employed to create holes in glass for fittings or decorative purposes, enhancing both functionality and design in glass installations. Each of these machines plays a fundamental role in the overall glass processing workflow, ensuring quality and efficiency in production.

Key Features to Consider When Buying Glass Processing Machines

When purchasing glass processing machines, it's essential to consider several key features that will significantly impact your efficiency and the quality of your output. First and foremost, assess the type of glass you will be working with; different machines are optimized for specific thicknesses and materials. For instance, if your operations involve tempered or laminated glass, ensure the machine can handle these specifications effectively. Additionally, pay attention to the machine's versatility; a multi-functional machine can save costs and space by handling multiple tasks such as cutting, edging, and drilling.

Another crucial aspect to consider is automation level. Machines with advanced automation capabilities can streamline your production process, reducing labor costs and increasing precision. Look for options with user-friendly interfaces and programmable settings that facilitate quick adjustments for various projects. Moreover, assess the machine's maintenance requirements; investing in models that offer easy access to components can help minimize downtime and prolong the equipment's lifespan.

Tips: Before making a purchase, consult with industry professionals or visit trade shows to see machines in action. This firsthand experience can provide valuable insights into the functionality and efficiency of different models. Additionally, consider the after-sales support and warranty offered, as reliable customer service can be vital for troubleshooting and ensuring that your operations run smoothly.

Top 10 Glass Processing Machines: A Comprehensive Guide for Buyers

| Machine Type |

Key Features |

Max Glass Size (mm) |

Thickness Range (mm) |

Power Consumption (kW) |

Price Range (USD) |

| Glass Cutting Machine |

Automatic cutting, precise dimensions, software integration |

3200 |

3 - 19 |

15 |

$15,000 - $30,000 |

| Glass Edging Machine |

Multi-edge processing, speed control, diamond wheels |

2400 |

5 - 25 |

12 |

$10,000 - $25,000 |

| Glass Drilling Machine |

CNC control, multiple drilling options, automatic feed |

2000 |

4 - 15 |

7 |

$8,000 - $20,000 |

| Glass Laminating Machine |

High temperature control, vacuum pressing, safety features |

3000 |

3 - 20 |

20 |

$25,000 - $50,000 |

| Glass Polish Machine |

Automatic polishing, adjustable speed, low abrasiveness |

1500 |

2 - 12 |

5 |

$3,000 - $10,000 |

| Glass Tempering Furnace |

High speed, uniform heating, digital controls |

3500 |

4 - 19 |

50 |

$40,000 - $100,000 |

| Glass Cutting Robot |

Robotic arm, precision cutting, software control |

2800 |

3 - 15 |

10 |

$20,000 - $60,000 |

| Glass Handling System |

Automated transport, safety controls, scalable |

N/A |

N/A |

5 |

$15,000 - $35,000 |

| Glass Cleaning Machine |

High efficiency, eco-friendly, adjustable settings |

1800 |

2 - 12 |

8 |

$5,000 - $12,000 |

| Glass Serigraphy Machine |

Digital printing capabilities, high resolution, UV curing |

2200 |

3 - 8 |

12 |

$30,000 - $70,000 |

Top 10 Glass Processing Machines: Detailed Reviews and Comparisons

When it comes to glass processing machines, understanding the available options and their features is essential for making an informed decision. A report by the International Glass Association highlighted that the glass processing machinery market is expected to reach approximately $9 billion by 2026, driven by advancements in technology and increased demand for energy-efficient solutions. With numerous manufacturers offering specialized equipment for cutting, grinding, and insulating glass, buyers must carefully examine the performance metrics and capabilities of each machine before purchase.

In particular, automated glass processing machines are gaining popularity due to their efficiency and precision. According to a survey by the Glass Manufacturers Industry Council, 68% of respondents indicated that automation in glass processing has significantly increased production rates while reducing labor costs. Buyers should compare specifications such as speed, operational flexibility, and energy consumption to find the optimal machine that aligns with their production requirements. Additionally, factors like ease of maintenance and the availability of technical support play a crucial role in ensuring long-term operational success. It is imperative that buyers not only focus on initial pricing but also consider the total cost of ownership, which can fluctuate based on machine efficiency and lifespan.

Top 10 Glass Processing Machines: Performance Comparison

Maintenance and Best Practices for Longevity of Glass Processing Machines

Proper maintenance of glass processing machines is crucial for ensuring their longevity and optimal performance. Regular inspections should be conducted to check for wear and tear on essential components such as blades, motors, and belts. Any signs of rust, wear, or misalignment should be addressed immediately to prevent further damage. Lubrication of moving parts is equally important, as it reduces friction and extends the life span of the machine. A well-lubricated machine operates more efficiently and produces better quality glass products.

In addition to mechanical upkeep, operators should also focus on the cleanliness of the machines. Dust and glass particles can accumulate over time, affecting the precision of the cuts and the overall quality of the finished product. Implementing a thorough cleaning routine that includes the removal of debris and the cleaning of all surfaces will help maintain the machine's functionality. Regular training for operators on best practices can ensure that they are knowledgeable about handling machines properly, reducing the risk of accidents and mishandling, which can lead to costly repairs or replacements.

Home

About Us

Products

UPVC PVC Window Machine

Aluminum Window Machine

Glass Cutting Machine

Glass Edging Machine

Insulating Glass Machine

Glass lifting machine

Glass Washing Machine

Glass Laminating Machine

Glass Sandblasting Machine

Glass Drilling Machine

CNC Glass Working Center

CNC Non-Metal Cutting Machine

The Other Glass Machinery

Application

Download

News

Contact Us