Top 7 Tips for Choosing the Right CNC Glass Milling Machine for Your Business

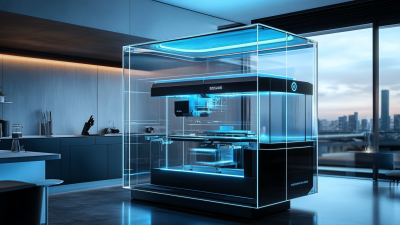

In today's rapidly evolving manufacturing landscape, the choice of machinery can significantly impact a business's efficiency and product quality. When it comes to precision glass machining, selecting the right CNC glass milling machine is paramount. These advanced machines not only streamline production processes but also enhance accuracy, allowing businesses to meet the increasing demands for high-quality glass products. As we look forward to 2025, it becomes essential for manufacturers to stay informed about the latest technologies and trends in CNC glass milling.

With numerous options available on the market, choosing the best CNC glass milling machine can be overwhelming. Understanding the specific needs of your business, such as the types of glass materials you will be working with and the complexity of designs required, is the first step in making an informed decision. Additionally, evaluating the features and capabilities of different machines can ensure that you invest in a reliable solution that will grow with your business. This article presents the top seven tips for selecting the right CNC glass milling machine, enabling you to make a choice that aligns with both current capabilities and future aspirations.

Understanding Your Business Needs for CNC Glass Milling Machines

When considering the acquisition of a CNC glass milling machine for your business, understanding your specific operational needs is paramount. According to a recent market analysis by Research And Markets, the global market for CNC milling machines is anticipated to reach USD 100 billion by 2025, reflecting a growing demand across various sectors, including glass processing. This makes it vital to tailor your choice of machine to fit your production capabilities, quality standards, and material specifications.

Moreover, factors such as the volume of production and the type of glass products being manufactured will influence your decision. For instance, a company focused on high-volume production may require a machine with rapid processing speeds and robust automation features. Concurrently, the complexity of designs you plan to produce should determine the machine’s resolution and precision capabilities. A study by Technavio indicates that over 60% of manufacturers prioritize precision and adaptability when selecting milling machines, emphasizing the significance of aligning your machine choice with your business goals and product specifications.

Evaluating the Technical Specifications of CNC Glass Milling Machines

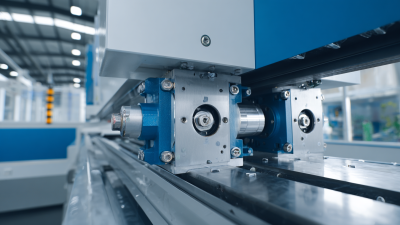

When evaluating the technical specifications of CNC glass milling machines, one must consider several key aspects that directly impact performance and efficiency. The machine's spindle speed plays a crucial role in determining how quickly and accurately it can process glass materials. A higher spindle speed generally allows for finer cutting and smoother finishes, making it essential to choose a machine that offers adjustable speeds tailored to various glass types.

Another vital specification is the machine's feed rate, which affects how swiftly the cutting tool moves across the glass surface. An optimal feed rate ensures a balance between speed and the quality of the cut. Additionally, the size and power of the machine's motors determine its ability to handle larger and thicker glass pieces. It’s important to select a CNC glass milling machine that not only meets your current production needs but also has the capacity for future growth, allowing for adaptability in a competitive market.

Assessing Budget Constraints and Cost-Effectiveness for Your Purchase

When considering the purchase of a CNC glass milling machine, assessing your budget constraints and ensuring cost-effectiveness is crucial for your business. Start by evaluating your financial situation and define a clear budget. Remember, a higher upfront investment does not always equate to better quality or efficiency. It’s essential to align your choices with your specific production needs – whether you need a machine for high-volume production or specialized tasks.

One tip is to prioritize features that directly impact your operations. Look for machines that offer versatility and durability. Technology improvements can result in significant savings over time, so investing in a model with advanced capabilities can pay off. Additionally, consider the total cost of ownership, including maintenance, operation, and potential downtime. Another important tip is to read reviews and seek recommendations from industry peers. This insight can help you gauge the long-term reliability and performance of different models while ensuring you stay within your financial means.

Top 7 Tips for Choosing the Right CNC Glass Milling Machine for Your Business

| Tip |

Description |

Estimated Cost |

Considerations |

| Define Your Needs |

Determine the types of glass and projects you'll work on. |

$0 |

Essential for narrowing down options. |

| Research Machine Specifications |

Look at RPM, tooling options, and precision levels. |

$2000 - $5000 |

Higher precision machines may cost more. |

| Assess Budget Constraints |

Determine how much you can spend without compromising quality. |

$5000 - $10000+ |

Consider financing options. |

| Calculate Total Cost of Ownership |

Include maintenance, tooling, and operational costs. |

$1000 - $3000/year |

Look for machines with lower TCO. |

| Consider Acquiring Used Equipment |

Used machinery can be budget-friendly. |

$3000 - $8000 |

Inspect for wear and performance issues. |

| Evaluate After-Sales Support |

Consider warranty, service, and parts availability. |

$0 |

Good support can save costs in the long run. |

| Read Customer Reviews |

Gain insights from existing users about their experiences. |

$0 |

Look for patterns in feedback. |

Researching Manufacturer Reputation and Customer Support Services

When selecting a CNC glass milling machine, it's crucial to prioritize both

manufacturer reputation and

customer support services. A solid reputation often reflects years of experience and reliability in the industry. According to a report by MarketsandMarkets, the global CNC machine market is expected to grow to $117.3 billion by 2025, underscoring the importance of aligning with reputable manufacturers who can meet high-quality standards. Researching customer reviews and testimonials can provide insights into manufacturers' performance in real-world applications, particularly regarding their products’ durability and precision.

In addition to reputation, responsive customer support is essential. Technical issues or maintenance needs can arise unexpectedly, so a manufacturer that offers robust support services can save valuable time and resources. A 2022 survey by TechValidate revealed that 89% of companies cited customer support as a critical factor in their purchasing decision. Evaluating the availability of support resources, such as online tutorials, troubleshooting assistance, and spare parts distribution, can greatly enhance operational efficiency.

Before finalizing your choice, ensure that the manufacturer provides comprehensive after-sales support and training services. This not only enhances your team's competency in handling the machinery but also helps prevent downtime and production losses. By focusing on these aspects, you can confidently invest in a CNC glass milling machine that aligns with your business needs.

Exploring Customization Options and Scalability for Future Growth

When investing in a CNC glass milling machine for your business, understanding customization options and scalability is crucial for future growth.

Research indicates that the global CNC machine market is expected to reach $100 billion by 2025, with demand driven by industries seeking tailored solutions to meet specific production needs. Customizable CNC machines can accommodate varying glass sizes, shapes, and complexities, offering businesses the flexibility to adapt their offerings and stay competitive.

Moreover, scalability ensures that as your business grows, your CNC machine can evolve alongside it. Companies that invest in scalable CNC systems can increase production capacity without extensive new equipment purchases. According to a report by Mordor Intelligence, businesses that prioritize scalability experience a 25% increase in operational efficiency and a significant reduction in production downtime.

This adaptability not only prepares businesses for fluctuating demands but also secures their market position in an ever-evolving landscape. By focusing on these two critical aspects, you can make a more informed decision when selecting the right CNC glass milling machine for your operations.

Home

About Us

Products

UPVC PVC Window Machine

Aluminum Window Machine

Glass Cutting Machine

Glass Edging Machine

Insulating Glass Machine

Glass lifting machine

Glass Washing Machine

Glass Laminating Machine

Glass Sandblasting Machine

Glass Drilling Machine

CNC Glass Working Center

CNC Non-Metal Cutting Machine

The Other Glass Machinery

Application

Download

News

Contact Us