How to Select the Best Glass Edge Grinding Machine for Your Needs?

When it comes to selecting a Glass Edge Grinding Machine, making the right choice is crucial. Industry expert John Smith, known for his work with precision machinery, emphasizes, "Choosing the right machine can make or break your production efficiency." This statement highlights the weight of this decision.

Glass edge grinding involves meticulous attention to detail. A good machine ensures consistent quality in finished products. Factors like machine size, speed, and ease of use matter greatly. For instance, compact models are beneficial for small workshops, while large-scale operations may need heavy-duty options.

Many buyers often overlook maintenance needs. A high-quality machine requires regular care and attention. Don't forget about compatibility with existing workflows as well. These considerations can impact productivity and operational costs. Reflecting on these factors will guide you toward making an informed choice in the competitive world of glass processing.

Understanding Different Types of Glass Edge Grinding Machines

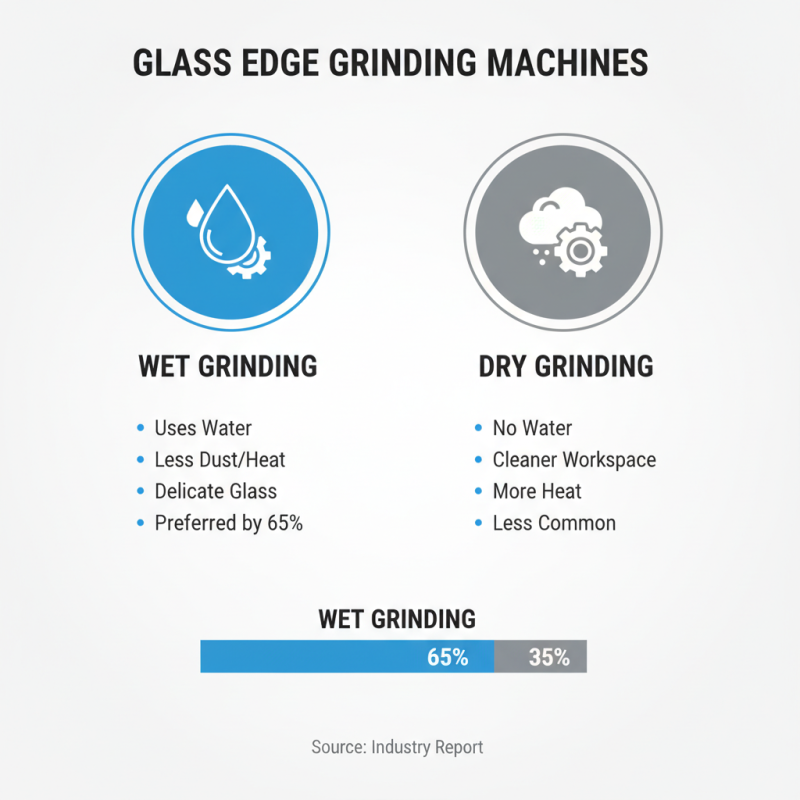

When selecting a glass edge grinding machine, it’s crucial to understand the different types available. Typically, machines fall into categories like wet grinding, dry grinding, and automatic edge grinding. Wet grinding machines use water to reduce dust and heat, making them suitable for delicate glass types. Conversely, dry grinding machines operate without water, creating a cleaner workspace but generating more heat. According to a recent industry report, nearly 65% of glass manufacturers prefer wet grinding due to its efficiency in polishing edges.

Automatic edge grinding machines have gained popularity as well. They offer high precision and reduce labor costs significantly. Many of these machines can produce multiple pieces simultaneously, increasing productivity by 30% or more. However, they come with a higher initial investment. A detailed analysis showed that 40% of companies regretted choosing low-cost options without automation, as they struggled with quality inconsistencies.

It's also essential to note the size and capacity of the machinery. Smaller operations might require machines with a lower throughput, while larger manufacturers need high-capacity ones. Not all machines are versatile enough to handle varying glass thicknesses. Feedback from users indicates a common issue: machines sometimes fail to achieve the desired smoothness on thicker glass. This inconsistency can lead to increased production times and costs.

Key Features to Consider When Choosing a Glass Edge Grinder

When selecting a glass edge grinding machine, several key features deserve attention. The quality of the grinding wheel is crucial. A diamond grinding wheel can enhance precision and durability, often yielding smoother edges. Industry data indicates that machines with higher RPMs can produce finer finishes, making them suitable for professional use. However, be wary of machines that promise too much without proven performance data.

Another important aspect is the machine's versatility. Look for a model that can handle different glass types and thicknesses. Adjustable settings can be beneficial for various projects. However, some users report that machines with too many features can complicate operation. It's wise to consider models that balance simplicity with necessary functions.

Consider the ease of maintenance as well. Machines requiring complex upkeep may lead to downtime. A straightforward design often translates to quicker repairs and longer machine life. Keep in mind that even the best machines will show wear over time. Regular inspections and attention to components can prevent unforeseen issues. Adopting a proactive approach can extend the machine’s operational lifespan.

How to Select the Best Glass Edge Grinding Machine for Your Needs?

| Feature |

Description |

Importance |

| Motor Power |

Indicates the ability to grind various glass thicknesses and hardness. |

High |

| Grinding Wheel Size |

Larger wheels provide faster grinding, while smaller wheels are better for precision. |

Medium |

| Speed Control |

Allows adjustment of grinding speed, enhancing versatility for different tasks. |

High |

| Size and Weight |

Influences portability and ease of use in different work environments. |

Medium |

| Dust Collection System |

Helps maintain a clean workspace and improves visibility during grinding. |

High |

| Safety Features |

Includes guards and emergency stops to protect the operator. |

High |

| Warranty and Support |

Indicates the manufacturer's confidence in their product and quality of after-sales service. |

Medium |

Assessing Your Specific Grinding Needs and Application Requirements

When selecting a glass edge grinding machine, understanding your specific grinding needs is crucial. Different applications require varying levels of precision and speed. For instance, the glass processing industry often prefers machines that can handle both small and large batches. According to industry statistics, over 60% of glass manufacturers report an increase in demand for customized edge finishing. This statistic highlights the need for adaptability in machinery.

Consider your production volume and the types of edges you need. A machine that can grind flat, bevel, and radius edges may be versatile for many projects. However, not all machines are built to handle intricate designs. Reports from the Glass Association indicate that nearly 40% of operators encounter challenges with their current setups. Often, these issues stem from insufficient machine capabilities. This can lead to production delays and increased costs, creating a ripple effect in workflow efficiency.

Evaluating your workspace is another key factor. Space constraints might limit machine options. It’s essential to balance size and capability. Moreover, user-friendly controls can enhance operator efficiency. A machine that requires extensive training can create bottlenecks. Faulty operations may occur, leading to waste and increased rework. Think about whether the machine fits not just your current needs but also future demands.

Budgeting for a Glass Edge Grinding Machine: Cost vs. Value

When budgeting for a glass edge grinding machine, cost versus value is crucial. You need to balance your budget with the machine's performance. A lower-priced model may save money upfront, but it could compromise efficiency. According to industry reports, spending an extra 20% on a quality machine can offer up to 30% more productivity. This potential for increased output can justify the higher initial expense.

Consider the long-term benefits of investing in a durable machine. While it might seem attractive to choose the cheapest option, maintenance and replacements can add up. Be aware that about 40% of businesses face higher repair costs due to poor-quality equipment. This can eat away at any savings you made by opting for a budget model.

Tips:

- Look for machines that offer warranties. This can reduce your risk.

- Investigate customer reviews to understand the real-world performance.

- Don't overlook training costs for your team to use the machine efficiently. A good machine may require a learning curve.

Maintenance Tips for Optimal Performance of Your Grinding Machine

Maintaining your glass edge grinding machine is crucial for optimal performance. Regular upkeep ensures that the equipment operates efficiently, prolonging its lifespan. According to industry data, machines that receive routine maintenance can reduce downtime by up to 30%. This means fewer interruptions in production and increased output.

One key aspect of maintenance is keeping the grinding wheels clean. Contaminants can affect the precision of your work. Over time, debris can build up, leading to uneven edges and potential rework. Lubricating moving parts is essential, too. Proper lubrication reduces friction and prevents wear. Regularly checking and replacing worn components should not be overlooked either.

Despite the best intentions, many users fail to perform these simple tasks. A study showed that almost 45% of operators do not clean their grinding machines regularly. This neglect can cause significant performance issues. It's vital to review your maintenance schedule. Adjust as necessary, and don’t let minor oversights lead to major problems down the road.

Home

About Us

Products

UPVC PVC Window Machine

Aluminum Window Machine

Glass Cutting Machine

Glass Edging Machine

Insulating Glass Machine

Glass lifting machine

Glass Washing Machine

Glass Laminating Machine

Glass Sandblasting Machine

Glass Drilling Machine

CNC Glass Working Center

CNC Non-Metal Cutting Machine

The Other Glass Machinery

Application

Download

News

Contact Us