Revolutionizing Glass Production: The Future of Glass Edge Grinding Machines in Manufacturing

The manufacturing landscape is on the brink of transformation, particularly in the glass production sector, where efficiency and precision are paramount. Among the pivotal technologies driving this change is the Glass Edge Grinding Machine, a sophisticated tool designed to enhance the processing of glass with exceptional accuracy.

As industries demand higher-quality finishes and reduced production times, the evolution of these machines becomes increasingly crucial. The integration of advanced automation, artificial intelligence, and innovative grinding techniques is set to redefine traditional manufacturing methods. This shift not only promises to elevate the quality of finished products but also aims to streamline operations, reduce waste, and ultimately lower costs. In this guide, we will explore the innovative approaches to glass edge grinding machines and how they herald a new era in glass manufacturing, paving the way for increased productivity and sustainability in the industry.

As industries demand higher-quality finishes and reduced production times, the evolution of these machines becomes increasingly crucial. The integration of advanced automation, artificial intelligence, and innovative grinding techniques is set to redefine traditional manufacturing methods. This shift not only promises to elevate the quality of finished products but also aims to streamline operations, reduce waste, and ultimately lower costs. In this guide, we will explore the innovative approaches to glass edge grinding machines and how they herald a new era in glass manufacturing, paving the way for increased productivity and sustainability in the industry.

Innovative Technologies Transforming Glass Edge Grinding Processes

The glass manufacturing industry is experiencing a significant transformation, particularly in the realm of edge grinding technologies. Advanced automated systems are now integrating AI and machine learning to optimize the grinding processes, increasing precision and efficiency. According to a recent report by MarketsandMarkets, the global edge grinding machine market is anticipated to reach $2.3 billion by 2025, reflecting a CAGR of 4.5% from 2020. This growth underscores the industry's demand for innovative solutions that enhance product quality while reducing operational costs.

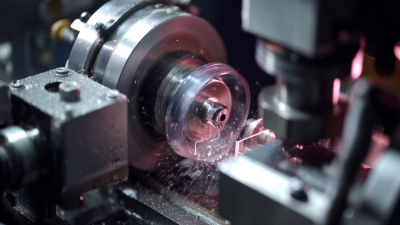

One of the most noteworthy advancements includes the adoption of robotic automation in glass edge grinding. These machines utilize real-time data feedback to adjust grinding parameters dynamically, ensuring a consistent finish. Additionally, innovations such as diamond belt grinding technology allow for faster processing times without compromising on quality. For manufacturers, this means not only improved throughput but also less material wastage—an important consideration as sustainability becomes increasingly essential in manufacturing practices.

**Tip:** To stay competitive, consider investing in training for your team to effectively operate and maintain these advanced machines. This investment not only boosts efficiency but also fosters a culture of innovation within your workforce, crucial for the industry's ongoing evolution.

Automation in Glass Edge Grinding: Enhancing Efficiency and Precision

The advent of automation in glass edge grinding has marked a significant milestone in the manufacturing sector, particularly in enhancing operational efficiency and precision. Modern glass edge grinding machines are now equipped with advanced robotics and intelligent systems designed to streamline the grinding process. These automated solutions not only reduce manual labor but also minimize human error, ensuring that each piece of glass is finished to exact specifications. The integration of sensors and artificial intelligence allows for real-time monitoring and adjustments, optimizing the grinding operation for consistency and quality.

The advent of automation in glass edge grinding has marked a significant milestone in the manufacturing sector, particularly in enhancing operational efficiency and precision. Modern glass edge grinding machines are now equipped with advanced robotics and intelligent systems designed to streamline the grinding process. These automated solutions not only reduce manual labor but also minimize human error, ensuring that each piece of glass is finished to exact specifications. The integration of sensors and artificial intelligence allows for real-time monitoring and adjustments, optimizing the grinding operation for consistency and quality.

Moreover, the shift towards automation facilitates greater production scalability. Manufacturers can respond swiftly to varying market demands without compromising quality or efficiency. Automated glass edge grinding machines can operate continuously, leading to higher output rates and reduced lead times. This technological evolution brings significant cost savings for manufacturers as well, as fewer resources are wasted on inefficient processes and rework. The future of glass manufacturing lies in embracing these automated systems, which promise not only to enhance operational workflows but also to elevate the overall craftsmanship involved in glass production.

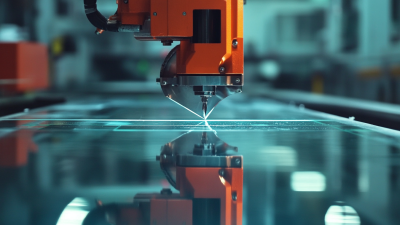

Smart Sensors and IoT Integration in Glass Manufacturing Equipment

The integration of smart sensors and IoT technology in glass manufacturing equipment is poised to transform the industry significantly. By equipping glass edge grinding machines with advanced sensors, manufacturers can monitor the grinding process in real-time, leading to enhanced precision and reduced material waste. According to a recent market report from Research and Markets, the global smart sensor market in the manufacturing sector is expected to grow at a CAGR of 21% through 2027, driven by the increasing demand for automated and efficient production processes.

Moreover, IoT integration enables machines to communicate seamlessly, facilitating predictive maintenance and minimizing downtime. This interconnectivity allows manufacturers to gather and analyze data more effectively, resulting in streamlined operations and improved product quality. A study released by McKinsey highlights that implementing IoT in production can lead to a potential reduction of manufacturing costs by 20-30%. As glass production continues to adapt to these technological advancements, the future looks promising for manufacturers who embrace these innovations.

Sustainability Practices in Modern Glass Edge Grinding Machines

The advancement of glass edge grinding machines is significantly influenced by the growing focus on sustainability in manufacturing practices. As the glass cutting machine market is projected to expand from USD 615.2 million in 2025 to USD 818.8 million by 2035, with a CAGR of 3.2%, the incorporation of environmentally friendly technologies is becoming essential. Modern glass edge grinding machines are now being designed to minimize waste and energy consumption, employing innovative techniques and materials that align with global sustainability goals.

Tips for manufacturers seeking to enhance sustainability in glass production include investing in energy-efficient motors and drives that can reduce power consumption during the grinding process. Additionally, exploring software solutions that optimize operations can lead to lower material waste and improved overall efficiency. It's also beneficial to assess the lifecycle impact of equipment, ensuring that recyclable and biodegradable materials are prioritized.

Furthermore, collaborations between technology developers and glass manufacturers can foster a culture of sustainability, resulting in cutting-edge solutions that not only meet industry demands but also contribute to a healthier planet. By embracing these sustainable practices, manufacturers will not only comply with regulations but also appeal to environmentally conscious consumers, making sustainability a core aspect of their operational strategy.

The Role of AI in Reducing Waste and Optimizing Glass Production

The integration of artificial intelligence (AI) in glass production, particularly in edge grinding machines, is set to revolutionize the industry by significantly reducing waste and enhancing efficiency. Historically, glass manufacturing has faced challenges in maintaining precision while managing resource consumption. However, with the deployment of AI algorithms, manufacturers can optimize cutting processes, ensuring that materials are used effectively and minimizing the generation of scrap glass.

Moreover, AI-driven technology enables real-time monitoring and adjustments throughout the production cycle. This not only streamlines operations but also aligns with sustainability efforts in the manufacturing sector. As the world increasingly shifts towards eco-friendly practices, the ability of AI to analyze production patterns and predict waste potential becomes crucial. This advancement promises not only to bolster profitability but also to contribute positively to environmental conservation, making glass production both efficient and sustainable for the future.

Revolutionizing Glass Production: The Future of Glass Edge Grinding Machines in Manufacturing

| Metric |

Value |

| Average Waste Reduction (%) |

30% |

| Increase in Production Efficiency (%) |

25% |

| Average Time Saved per Batch (minutes) |

15 minutes |

| Energy Consumption Reduction (%) |

20% |

| Improvement in Product Quality Rating (out of 10) |

9/10 |

| Projected Market Growth Rate (%) |

10% |

| Annual Cost Savings from AI Optimization ($) |

$250,000 |

Home

About Us

Products

UPVC PVC Window Machine

Aluminum Window Machine

Glass Cutting Machine

Glass Edging Machine

Insulating Glass Machine

Glass lifting machine

Glass Washing Machine

Glass Laminating Machine

Glass Sandblasting Machine

Glass Drilling Machine

CNC Glass Working Center

CNC Non-Metal Cutting Machine

The Other Glass Machinery

Application

Download

News

Contact Us

As industries demand higher-quality finishes and reduced production times, the evolution of these machines becomes increasingly crucial. The integration of advanced automation, artificial intelligence, and innovative grinding techniques is set to redefine traditional manufacturing methods. This shift not only promises to elevate the quality of finished products but also aims to streamline operations, reduce waste, and ultimately lower costs. In this guide, we will explore the innovative approaches to glass edge grinding machines and how they herald a new era in glass manufacturing, paving the way for increased productivity and sustainability in the industry.

As industries demand higher-quality finishes and reduced production times, the evolution of these machines becomes increasingly crucial. The integration of advanced automation, artificial intelligence, and innovative grinding techniques is set to redefine traditional manufacturing methods. This shift not only promises to elevate the quality of finished products but also aims to streamline operations, reduce waste, and ultimately lower costs. In this guide, we will explore the innovative approaches to glass edge grinding machines and how they herald a new era in glass manufacturing, paving the way for increased productivity and sustainability in the industry.