The global market for glass breaking tables has seen a significant uptick in demand, driven by advancements in manufacturing technology and increased applications across various industries. According to a report by Allied Market Research, the market size for specialized glass breaking equipment is expected to reach USD 120 million by 2025, growing at a CAGR of 6% from 2020. This rise can be attributed to the growing adoption of glass in construction, automotive, and consumer goods, necessitating robust solutions for safe and efficient glass breaking processes.

Furthermore, the appeal of elite Chinese manufacturing lies in its ability to offer high-quality products at competitive prices, catering to a global clientele. A study published by Market Research Future indicates that Asia-Pacific holds the largest share of the glass breaking table market, accounting for over 40% due to the region's rapid industrialization and urbanization. The integration of innovative features, such as automated operating systems and safety enhancements, is increasingly attracting international partnerships and investments, thereby facilitating a seamless expansion into global markets.

As the demand for reliable glass processing tools grows, elite Chinese manufacturers are well-positioned to meet these emerging needs, reshaping the industry's landscape.

Home

About Us

Products

UPVC PVC Window Machine

Aluminum Window Machine

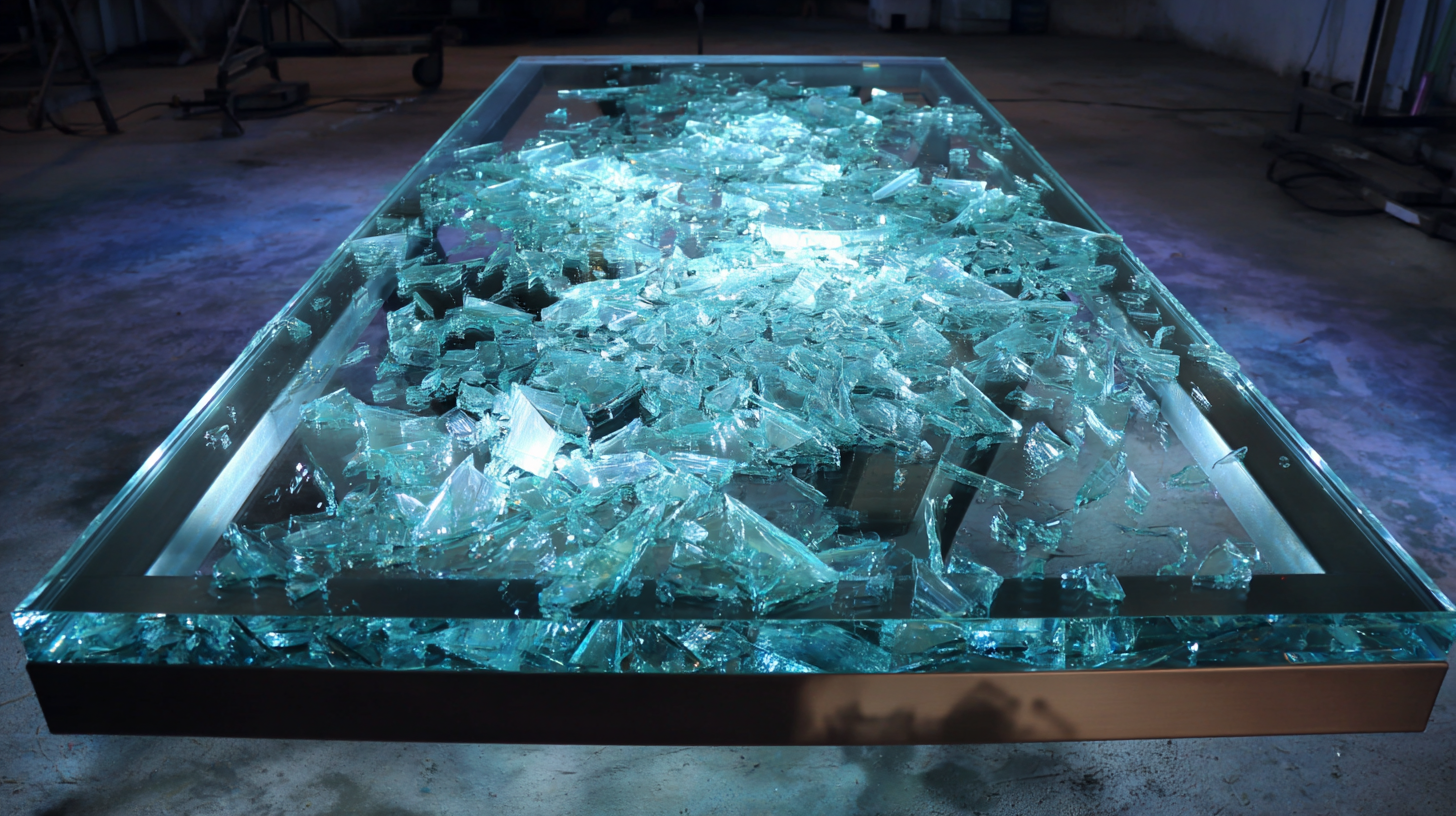

Glass Cutting Machine

Glass Edging Machine

Insulating Glass Machine

Glass lifting machine

Glass Washing Machine

Glass Laminating Machine

Glass Sandblasting Machine

Glass Drilling Machine

CNC Glass Working Center

CNC Non-Metal Cutting Machine

The Other Glass Machinery

Application

Download

News

Contact Us