How to Achieve Precision in Glass Cutting with a CNC Glass Cutting Machine

In the realm of modern manufacturing, precision is paramount, and the advent of the CNC Glass Cutting Machine has revolutionized how glass is processed. According to a recent report by the International Glass Association, the use of CNC technology in glass cutting has increased efficiency by over 30% while reducing material waste by nearly 25%. This is a significant advancement for industries ranging from architecture to automotive, where the demand for high-quality glass components is continually growing. By employing advanced algorithms and state-of-the-art machinery, manufacturers can achieve intricate designs and exact specifications that were once deemed impossible. As companies strive for excellence and competitiveness, understanding how to effectively utilize CNC Glass Cutting Machines becomes essential for producing flawless glass products that meet the exacting standards of today’s market.

Understanding CNC Glass Cutting Machines and Their Precision Capabilities

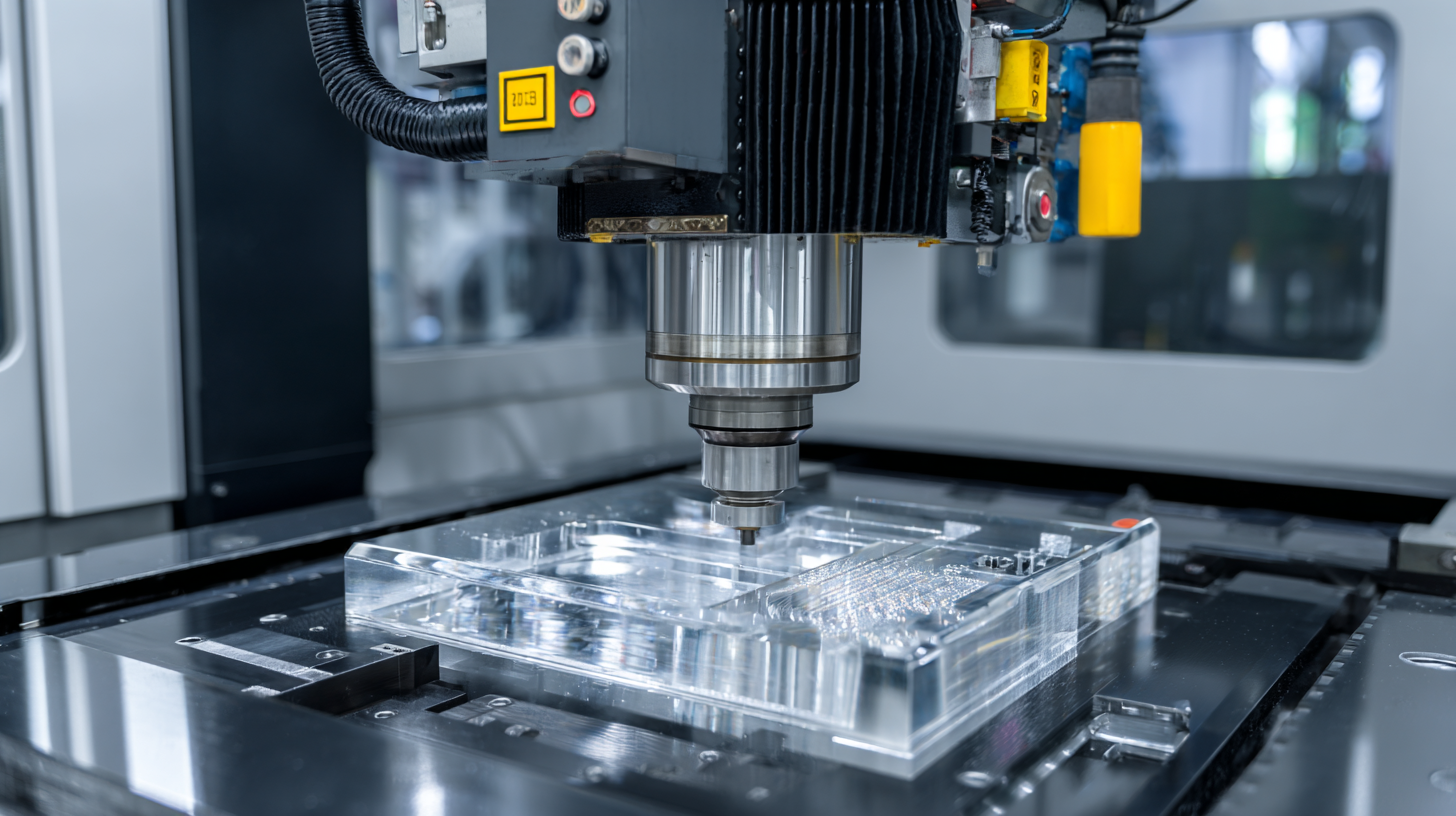

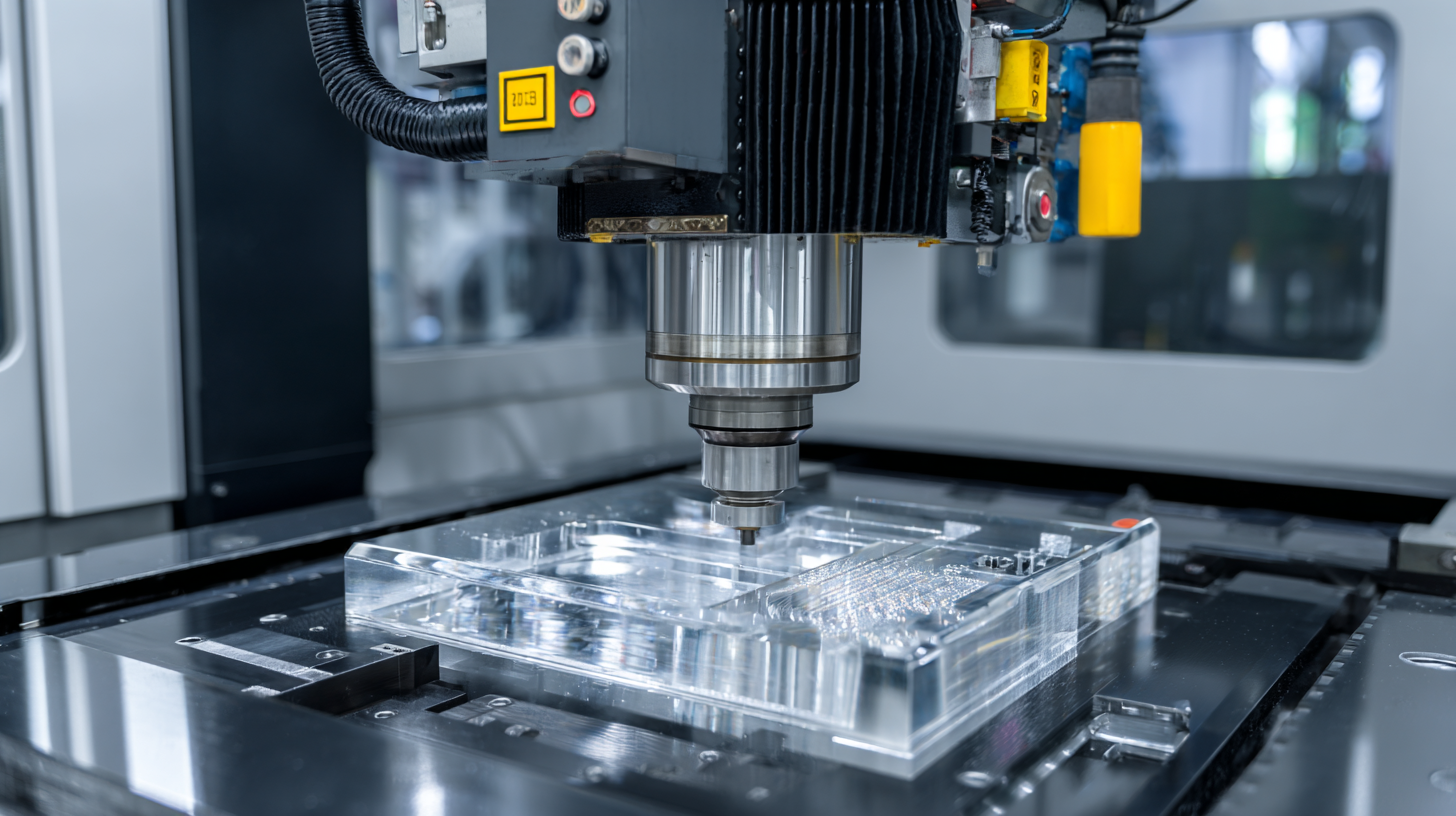

CNC glass cutting machines are revolutionizing the way glass is processed, offering unparalleled precision and efficiency. These machines utilize computer numerical control technology to automate the cutting process, allowing for complex designs and intricate shapes that would be difficult or impossible to achieve with traditional methods. The precision capabilities of CNC machines stem from their ability to utilize advanced software and high-speed cutting heads, which ensure clean, accurate cuts with minimal waste.

One of the key advantages of CNC glass cutting machines is their ability to maintain consistent quality across large production runs. Their precision engineering allows for exact repeatability, making it ideal for businesses looking to produce uniform components. Additionally, the integration of laser or diamond cutting techniques enhances the precision even further, ensuring that the finished pieces meet exact specifications. This level of accuracy not only improves the aesthetic quality of the final product but also enhances safety and functionality in various applications, from architectural glass to custom automotive parts.

Key Factors Influencing Precision in CNC Glass Cutting Processes

Achieving precision in glass cutting with a CNC glass cutting machine hinges on several key factors that influence the overall process. One of the most critical elements is the quality of the cutting tool itself. High-precision diamond blades, designed for specific thicknesses and types of glass, ensure clean cuts and minimize chipping. Additionally, maintaining the sharpness of these tools through regular maintenance contributes significantly to precision, as dull blades can lead to inaccuracies and increased material wastage.

Another important factor is the calibration and setup of the CNC machine. Properly configuring the machine’s parameters, such as feed rate, cutting speed, and pressure, is essential for achieving ideal results. The integration of advanced software that allows for precise coding and path generation can further enhance accuracy. Finally, the ambient environment in which the cutting takes place should not be overlooked; factors such as temperature, humidity, and vibration can all affect the cutting process, leading to variations in precision. By focusing on these elements, manufacturers can optimize their CNC glass cutting processes for superior precision.

How to Achieve Precision in Glass Cutting with a CNC Glass Cutting Machine

| Factors |

Description |

Impact on Precision |

Best Practices |

| Machine Calibration |

Regular calibration ensures accuracy in cut dimensions. |

High impact; affects overall cutting precision. |

Perform calibration every month. |

| Cutting Speed |

Rate at which the cutter moves through the glass. |

Moderate impact; too fast can lead to miscuts. |

Adjust speed based on material thickness. |

| Tool Condition |

The state of the cutting tool affects the cut quality. |

High impact; worn tools can yield poor results. |

Replace tools regularly and inspect before use. |

| Glass Thickness |

Varies among different glass types and applications. |

Direct impact; affects cutting parameters. |

Adjust cutting parameters per glass thickness. |

| Software Settings |

Parameters set in CNC software to guide cutting. |

High impact; incorrect settings can lead to errors. |

Verify software settings before starting jobs. |

Best Practices for Setting Up CNC Parameters for Optimal Glass Cutting

Setting up CNC parameters accurately is crucial for achieving precision in glass cutting. The first step involves selecting the right cutting speed, which depends on the thickness and type of glass being processed. A slower speed can minimize chipping and cracking, particularly with fragile materials, while a faster speed is suitable for thicker glass. It is essential to consult the manufacturer's recommendations and adjust the parameters accordingly to balance efficiency with quality.

Another important consideration is the type of cutting tool used. Diamond-tipped tools are highly recommended for glass, as they provide a clean cut and reduce the risk of flaring. Additionally, maintaining the correct pressure during the cutting process is vital. Too much pressure can lead to undesirable flaws, while too little may cause incomplete cuts. Proper calibration of the machine and regular maintenance checks will ensure that the cutting tool operates optimally, leading to better overall results in glass craftsmanship.

Maintaining CNC Glass Cutting Machines for Enhanced Precision and Longevity

Maintaining CNC glass cutting machines is essential for achieving enhanced precision and extending their operational lifespan. Regular maintenance practices not only ensure the machines function at optimal levels but also prevent potential breakdowns that can lead to costly downtimes. Key maintenance activities include routine cleaning of cutting heads and tracking systems, regularly checking and replacing worn-out parts, and ensuring that all software is updated to the latest versions for improved performance and precision.

Furthermore, proper calibration of the CNC machine is vital. Periodic assessments of the cutting parameters can significantly improve accuracy in glass cutting. This could involve checking the alignment of the cutting tools and making necessary adjustments to maintain precision. Operators should also be trained in best practices for machine usage, as improper handling can lead to wear and tear, affecting the quality of the cutting and the longevity of the equipment.

Investing time in maintenance and operator training is crucial for sustaining high standards in glass cutting projects.

Case Studies: Successful Implementation of CNC Glass Cutting in the Industry

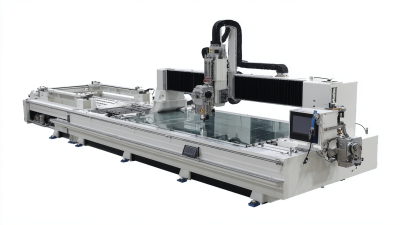

CNC glass cutting machines have revolutionized the industry by providing precise and efficient cutting solutions. One notable case study is the implementation of CNC technology at a leading glass manufacturer that specialized in architectural glass. By integrating a CNC cutting machine into their production line, the company improved its cutting accuracy by up to 99%, significantly reducing waste and improving operational efficiency. The software used in conjunction with the machine allowed for intricate designs to be programmed easily, enabling the manufacturer to meet customer demands for customized glass shapes quickly.

Another successful case comes from a company focused on automotive glass production. After adopting CNC technology, they saw a 30% reduction in production time. The precision of the CNC machine allowed for flawless cuts, which were critical for the safety and performance of automotive glass. This innovation not only enhanced product quality but also boosted the company’s reputation in the competitive market. The ease of use and reliability of CNC machines have poised them as essential tools for businesses aiming to excel in precision glass cutting.

Precision in Glass Cutting with CNC Machines: Case Studies Overview

Home

About Us

Products

UPVC PVC Window Machine

Aluminum Window Machine

Glass Cutting Machine

Glass Edging Machine

Insulating Glass Machine

Glass lifting machine

Glass Washing Machine

Glass Laminating Machine

Glass Sandblasting Machine

Glass Drilling Machine

CNC Glass Working Center

CNC Non-Metal Cutting Machine

The Other Glass Machinery

Application

Download

News

Contact Us