Unlocking Precision: The Revolutionary Impact of CNC Machines on Glass Cutting Techniques

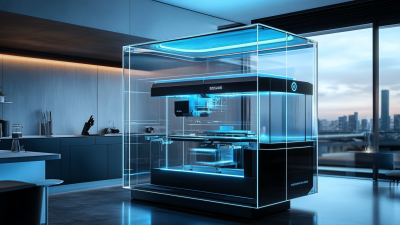

In recent years, the advent of CNC machine glass cutting has transformed the landscape of the glass manufacturing industry, marking a significant departure from traditional techniques. This revolutionary approach combines precision engineering with advanced software technology, enabling manufacturers to achieve unparalleled accuracy and efficiency in glass cutting processes. By leveraging the capabilities of computer numerical control (CNC), artisans and technicians can now create intricate designs with minimal waste, drastically reducing production time while enhancing product quality. The integration of CNC machines into glass cutting not only streamlines operations but also opens up new possibilities for creativity, allowing for more complex shapes and patterns that were previously unattainable. As we delve into the various aspects of this cutting-edge technology, it becomes evident that CNC machine glass cutting is not merely a trend but a fundamental shift that is reshaping how we think about and work with glass.

The Evolution of Glass Cutting: From Traditional Methods to CNC Innovations

The evolution of glass cutting techniques has undergone a significant transformation with the advent of Computer Numerical Control (CNC) machines. Traditional glass cutting methods, primarily reliant on manual labor and rudimentary tools, often led to inconsistencies and material wastage. According to a report by the Glass Association of North America, traditional cutting processes can result in up to 15% material loss due to inaccuracies. This inefficiency has driven the industry toward more precise and innovative solutions.

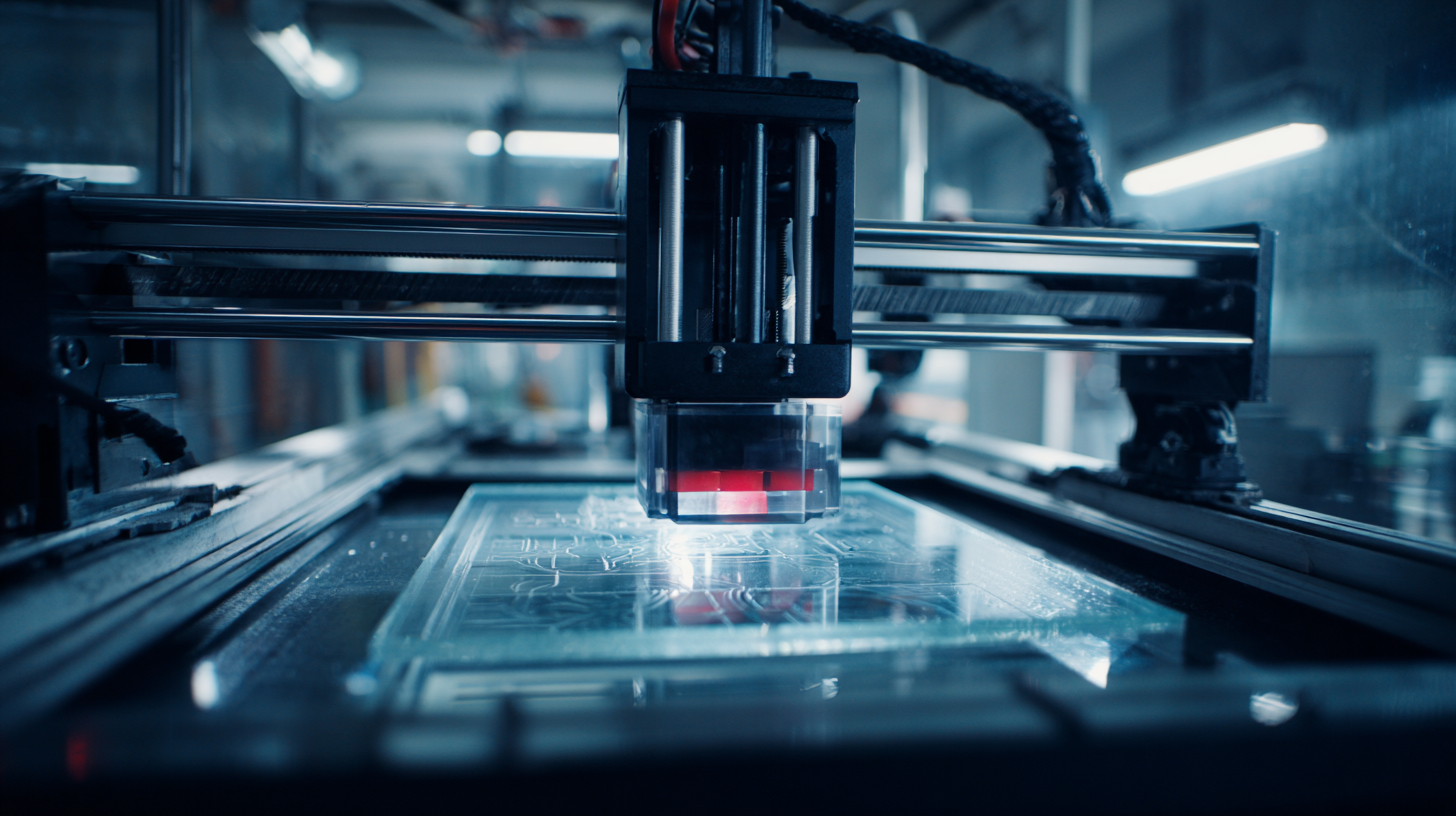

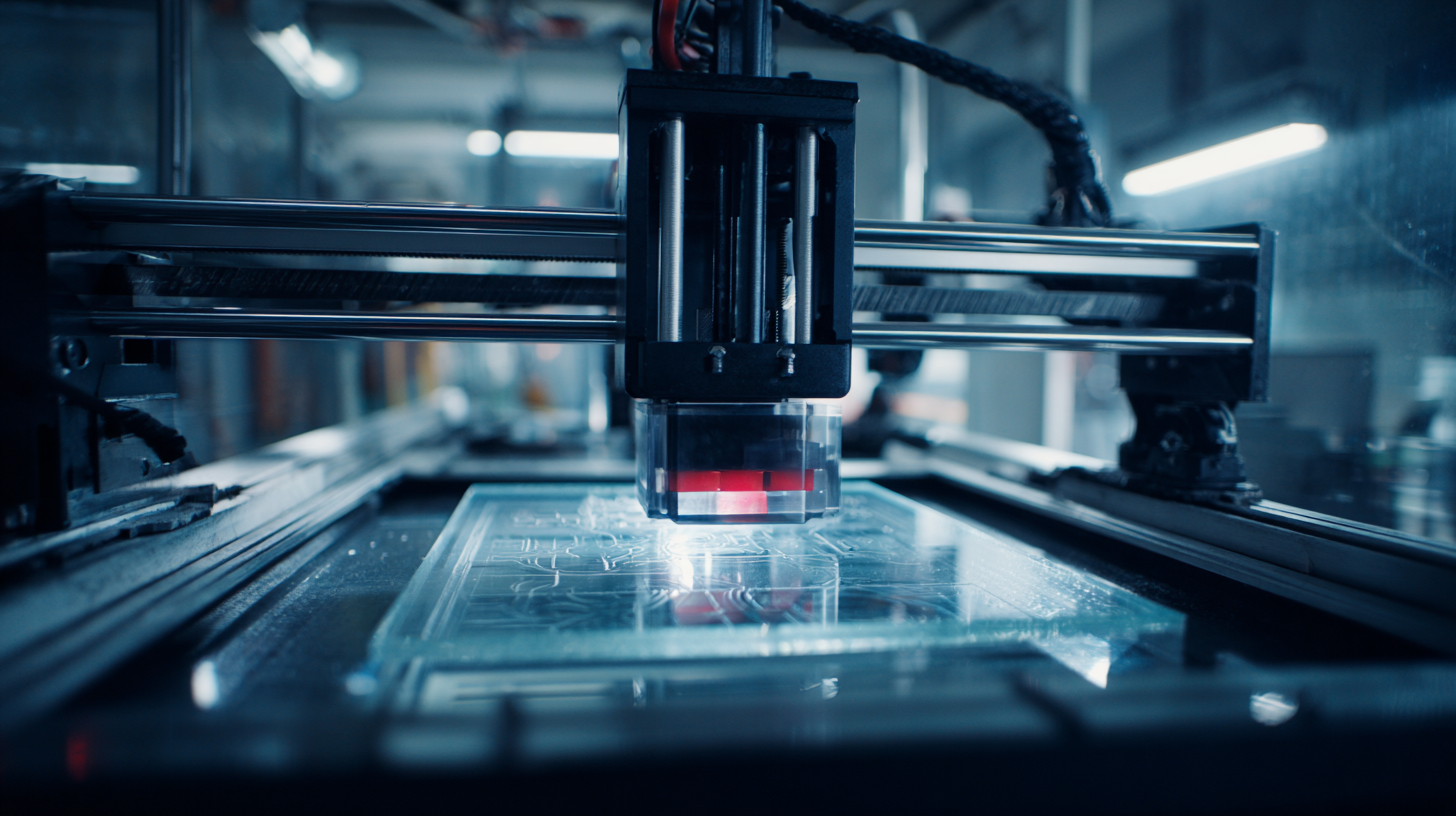

CNC technology has revolutionized glass cutting by integrating advanced computer algorithms that ensure high precision and minimal waste. With CNC machines, manufacturers can achieve accuracy levels of 0.1mm, drastically reducing the errors associated with human-operated cutting. A recent study published in the Journal of Manufacturing Processes highlighted that businesses utilizing CNC glass cutting reported a 30% increase in production efficiency. Moreover, the ability to create intricate designs with ease has opened new avenues for creativity in glass applications, further pushing the boundaries of what is achievable in the industry. The shift to CNC innovations not only enhances productivity but also fosters a more sustainable approach to glass manufacturing.

Understanding CNC Technology and Its Role in Modern Glass Cutting

CNC (Computer Numerical Control) technology has revolutionized the glass cutting industry by enhancing precision and efficiency. In traditional glass cutting methods, achieving intricate designs and uniformity could often lead to significant material waste and longer production times. However, according to a report by MarketsandMarkets, the global CNC machining market is projected to reach $100 billion by 2025, indicating a robust demand for these technologies across various sectors, including glass fabrication.

The integration of CNC machines into glass cutting allows for automated adjustments and real-time monitoring, which greatly reduces human error. For instance, a study from the Glass Association of North America noted that CNC-enhanced cutting processes can improve accuracy by up to 50%, leading to less scrap material and cost savings for manufacturers. Furthermore, CNC technology facilitates the creation of complex designs that were previously unattainable, further expanding the potential applications of cut glass in architecture and art. This shift not only streamlines production but also elevates the quality of the final products, paving the way for innovation within the glass industry.

Impact of CNC Machines on Glass Cutting Techniques

Advantages of CNC Machines in Achieving Precision and Efficiency

CNC machines have fundamentally transformed glass cutting techniques, offering unparalleled precision and efficiency in manufacturing processes. The adoption of CNC technology allows for intricate designs to be executed with high accuracy, significantly reducing waste and enhancing the quality of the final product. This technological shift is especially crucial in industries like aerospace and automotive manufacturing, where the precision of components is vital. According to a recent market analysis, the global CNC machine market size is projected to grow from $101.22 billion in 2025 to $195.59 billion by 2032, at a compound annual growth rate (CAGR) of 9.9%. This growth reflects the burgeoning demand for high-precision cutting techniques in diverse applications.

CNC machines have fundamentally transformed glass cutting techniques, offering unparalleled precision and efficiency in manufacturing processes. The adoption of CNC technology allows for intricate designs to be executed with high accuracy, significantly reducing waste and enhancing the quality of the final product. This technological shift is especially crucial in industries like aerospace and automotive manufacturing, where the precision of components is vital. According to a recent market analysis, the global CNC machine market size is projected to grow from $101.22 billion in 2025 to $195.59 billion by 2032, at a compound annual growth rate (CAGR) of 9.9%. This growth reflects the burgeoning demand for high-precision cutting techniques in diverse applications.

Furthermore, innovations such as CNC laser cutting and ablation have advanced the ability to work with superhard materials, expanding the possibilities within precision engineering. With industries increasingly leaning towards automation and intelligent robotics, the integration of CNC technologies is seen as a key driver of efficiency. By employing tools that can deliver consistent high-quality cuts at faster rates, manufacturers can achieve significant gains in productivity. The future of machining hinges on these advancements, solidifying CNC machines as indispensable assets for achieving precision and promoting innovation in today's competitive market.

Applications of CNC Glass Cutting in Various Industries

The advent of CNC (Computer Numerical Control) machines has brought a transformative shift across various industries, particularly in glass cutting techniques. With a market size projected to reach approximately USD 101.22 billion by 2025, the demand for precision and efficiency in material processing is driving innovation. CNC glass cutting not only enhances the accuracy of cuts but also reduces wastage, making it an attractive solution for manufacturers looking to optimize production.

In industries such as architecture, automotive, and electronics, the application of CNC glass cutting technology has become increasingly pertinent. For instance, in the architectural field, CNC machines facilitate intricate designs and personalized glass elements, allowing for creative freedom while maintaining structural integrity. Similarly, in the automotive sector, precise glass cutting is critical for components like windshields and windows, where exact dimensions are crucial for safety and functionality. By adopting CNC technology, industries are witnessing significant improvements in turnaround times and overall product quality, solidifying CNC glass cutting as a pivotal technique in modern manufacturing.

Future Trends: The Next Generation of CNC Technologies in Glass Fabrication

The evolution of CNC technologies is set to revolutionize the glass fabrication industry, presenting unprecedented precision and efficiency in glass cutting techniques. As VR and AR technologies rapidly mature, similar trends can be observed in CNC machinery, allowing for enhanced design capabilities and integration into production processes. The global market for CNC machines is expected to grow significantly, with industry reports indicating a CAGR of over 6% through the next decade. This expansion is driven by increasing demand for intricate glass designs and the need for mass customization across various sectors.

In the context of glass fabrication, the latest advancements in CNC technology enable automated and highly precise cutting processes. The integration of AI and machine learning is also playing a crucial role, providing manufacturers with the ability to optimize operations and reduce waste. As the industrial landscape shifts towards greater automation, the glass industry is poised to benefit from improved production workflows and reduced lead times. This technological shift parallels recent developments in other sectors, such as VR/AR, where accelerated growth and ecosystem advancement are creating synergies that can also be harnessed within the CNC market.

Home

About Us

Products

UPVC PVC Window Machine

Aluminum Window Machine

Glass Cutting Machine

Glass Edging Machine

Insulating Glass Machine

Glass lifting machine

Glass Washing Machine

Glass Laminating Machine

Glass Sandblasting Machine

Glass Drilling Machine

CNC Glass Working Center

CNC Non-Metal Cutting Machine

The Other Glass Machinery

Application

Download

News

Contact Us

CNC machines have fundamentally transformed glass cutting techniques, offering unparalleled precision and efficiency in manufacturing processes. The adoption of CNC technology allows for intricate designs to be executed with high accuracy, significantly reducing waste and enhancing the quality of the final product. This technological shift is especially crucial in industries like aerospace and automotive manufacturing, where the precision of components is vital. According to a recent market analysis, the global CNC machine market size is projected to grow from $101.22 billion in 2025 to $195.59 billion by 2032, at a compound annual growth rate (CAGR) of 9.9%. This growth reflects the burgeoning demand for high-precision cutting techniques in diverse applications.

CNC machines have fundamentally transformed glass cutting techniques, offering unparalleled precision and efficiency in manufacturing processes. The adoption of CNC technology allows for intricate designs to be executed with high accuracy, significantly reducing waste and enhancing the quality of the final product. This technological shift is especially crucial in industries like aerospace and automotive manufacturing, where the precision of components is vital. According to a recent market analysis, the global CNC machine market size is projected to grow from $101.22 billion in 2025 to $195.59 billion by 2032, at a compound annual growth rate (CAGR) of 9.9%. This growth reflects the burgeoning demand for high-precision cutting techniques in diverse applications.