How to Optimize Your Workflow with Automatic Glass Cutting Machine

In today's fast-paced manufacturing environment, efficiency and precision are paramount, especially in industries involving glass processing. The advent of the Automatic Glass Cutting Machine has revolutionized the way businesses approach their workflows. Utilizing cutting-edge technology, these machines not only enhance the speed of production but also significantly improve the accuracy of cuts, reducing waste and minimizing errors. As companies strive to optimize their operations, integrating an Automatic Glass Cutting Machine into their workflow becomes increasingly essential. This guide will explore various strategies for maximizing the potential of these machines, ensuring that your production process is not only streamlined but also capable of meeting the demands of modern market dynamics. Join us as we delve into the best practices and innovative techniques to harness the full power of your Automatic Glass Cutting Machine, paving the way for a more efficient and profitable operation.

In today's fast-paced manufacturing environment, efficiency and precision are paramount, especially in industries involving glass processing. The advent of the Automatic Glass Cutting Machine has revolutionized the way businesses approach their workflows. Utilizing cutting-edge technology, these machines not only enhance the speed of production but also significantly improve the accuracy of cuts, reducing waste and minimizing errors. As companies strive to optimize their operations, integrating an Automatic Glass Cutting Machine into their workflow becomes increasingly essential. This guide will explore various strategies for maximizing the potential of these machines, ensuring that your production process is not only streamlined but also capable of meeting the demands of modern market dynamics. Join us as we delve into the best practices and innovative techniques to harness the full power of your Automatic Glass Cutting Machine, paving the way for a more efficient and profitable operation.

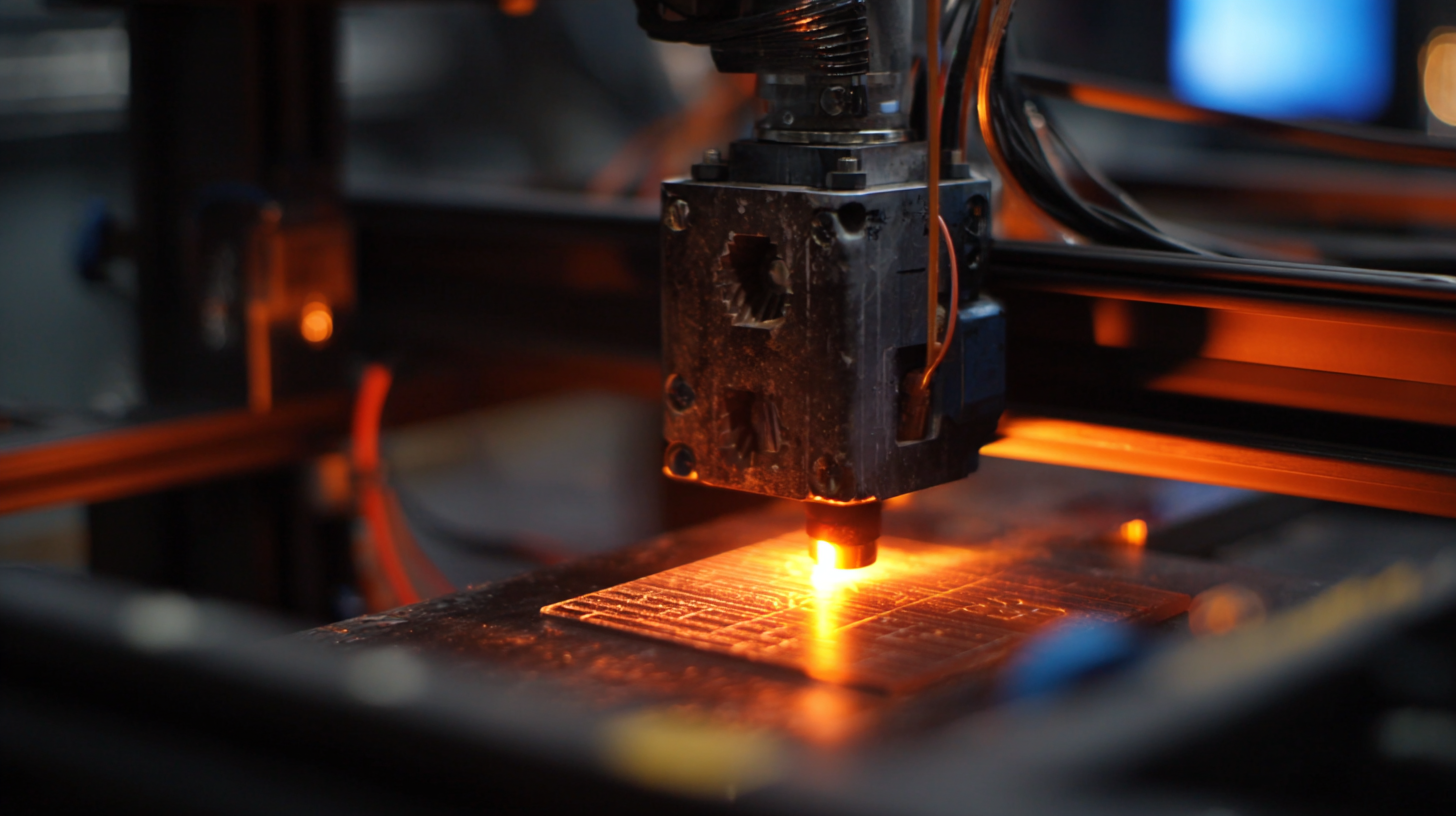

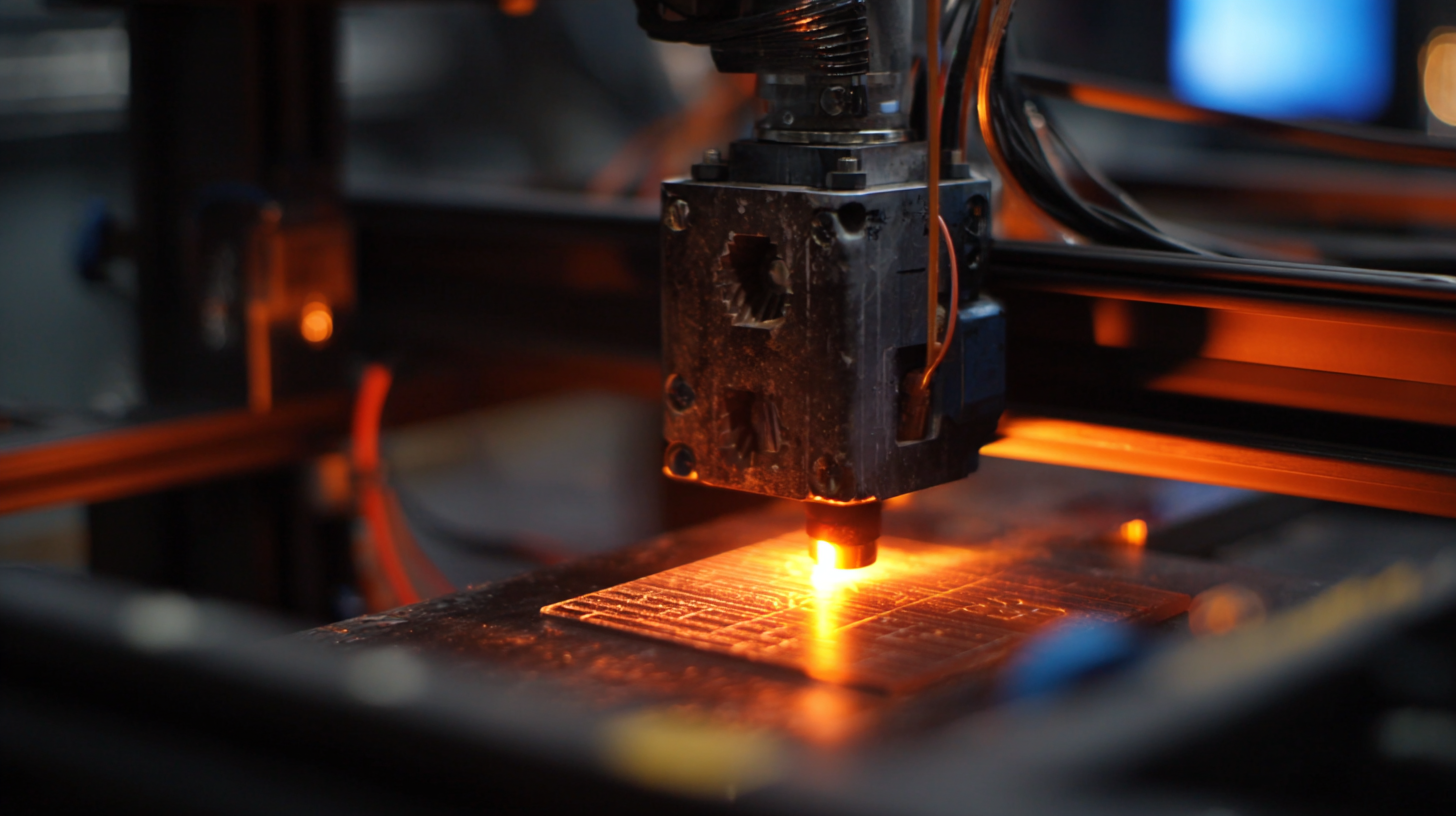

Understanding the Basics of Automatic Glass Cutting Machines

Automatic glass cutting machines have revolutionized the glass manufacturing industry by enhancing efficiency and precision. These machines utilize advanced technology, such as computer numerical control (CNC) systems, to optimize the cutting process.

According to a report by IBISWorld, the glass manufacturing sector has seen a consistent growth rate of 3.3% annually, largely attributed to the adoption of automation technologies. By minimizing manual errors and maximizing output, automatic glass cutting machines can process large volumes of glass quickly, thereby reducing production time and costs.

In addition to improving productivity, automatic glass cutting machines offer improved safety and working conditions. Traditionally, glass cutting was a labor-intensive process that posed numerous risks to workers. The integration of automatic systems allows for a more controlled environment, significantly decreasing the chances of accidents. A report from the National Safety Council highlights that workplaces that incorporate automated machinery see a 29% drop in injury rates. This shift not only protects employees but also enhances overall operational efficiency, making automatic glass cutting machines an essential investment for modern glass manufacturers.

Key Features to Look for in an Automatic Glass Cutting Machine

When choosing an automatic glass cutting machine, it's essential to consider its key features to enhance your workflow efficiency. One primary feature to look for is precision cutting technology, which ensures that the machine delivers accurate cuts with minimal waste. Machines equipped with advanced laser or diamond cutting tools can produce clean, precise edges, reducing the need for secondary processes and improving overall productivity.

Another crucial aspect is the software integration capabilities of the machine. A user-friendly interface that supports various file formats allows for seamless design adaptations and simplifies the cutting process. Additionally, programmable settings for different glass types and thicknesses can significantly speed up operations, enabling quick adjustments to cater to diverse project requirements. Finally, consider the machine’s maintenance and support services - reliable customer support and easy access to replacement parts can greatly reduce downtime and keep your production flowing smoothly.

Setting Up Your Workflow for Optimal Glass Cutting Efficiency

Setting up your glass cutting workflow for optimal efficiency is crucial to maximizing productivity and ensuring high-quality results. Recent advancements in glass cutting technology illustrate the importance of streamlined processes. For instance, a report from a well-known research group highlights that automating glass cutting can reduce production times by up to 30%, allowing manufacturers to meet growing demand more effectively while minimizing waste.

Integrating automatic glass cutting machines into your setup can significantly enhance operational workflows. Data indicates that companies using optimized cutting technologies experience improved yield rates, with some achieving up to 15% more usable glass from each sheet. By investing in specialized machinery and robust control software, firms can not only boost their production efficiency but also maintain superior product quality. This shift towards automation represents a critical step in modern glass manufacturing, reflecting a broader industry trend focused on leveraging technology for enhanced performance and sustainability.

Tips for Maintaining and Troubleshooting Your Glass Cutting Machine

Maintaining and troubleshooting your automatic glass cutting machine is essential for maximizing efficiency and minimizing downtime. According to a report by the Glass Association of North America, proper maintenance can extend the lifespan of glass cutting equipment by up to 30%. Regular checks on critical components such as the cutting head, conveyor belts, and pneumatic systems can prevent costly repairs and ensure consistent performance. Utilizing an organized maintenance schedule that includes daily surface checks and monthly deeper inspections can significantly enhance operational reliability.

Maintaining and troubleshooting your automatic glass cutting machine is essential for maximizing efficiency and minimizing downtime. According to a report by the Glass Association of North America, proper maintenance can extend the lifespan of glass cutting equipment by up to 30%. Regular checks on critical components such as the cutting head, conveyor belts, and pneumatic systems can prevent costly repairs and ensure consistent performance. Utilizing an organized maintenance schedule that includes daily surface checks and monthly deeper inspections can significantly enhance operational reliability.

When troubleshooting your glass cutting machine, it is crucial to have a clear understanding of common issues. For instance, misalignment can lead to inaccurate cuts, resulting in wasted materials and labor costs. The International Glass Association suggests that nearly 20% of production losses in the glass industry stem from improper cutting techniques or machine settings. Regular calibration and adjustments to the machine can drastically reduce these errors. Additionally, staying educated about machine-specific error codes and their meanings can expedite the diagnostic process, ensuring that your workflow remains uninterrupted. Implementing these best practices will not only enhance your operational efficiency but also contribute to overall cost savings.

Integrating Automation with Existing Glass Processing Operations

The integration of automation into existing glass processing operations is becoming increasingly essential, especially with the projected growth in the electronic kiln market. From 2025 to 2033, the market is expected to expand to $117 million, driven by a stable compound annual growth rate of 5.0%. This shift presents a significant opportunity for glass manufacturers to enhance productivity and reduce operational costs.

By incorporating automatic glass cutting machines, companies can achieve precision cutting and minimize material wastage. This technological advancement not only streamlines the workflow but also allows for greater flexibility in production schedules. With the growing demand for customizable glass products, the ability to integrate these automated systems into current operations can lead to improved turnaround times and increased customer satisfaction. Manufacturers that embrace automation will likely find themselves at a competitive advantage in an evolving market landscape, which highlights the necessity of adapting to modern processing techniques.

Optimization of Workflow with Automatic Glass Cutting Machines

This chart illustrates the time saved by integrating automatic glass cutting machines into existing operations. The data shows a significant reduction in hours required for glass cutting processes after the implementation of automation, optimizing overall workflow efficiency.

Home

About Us

Products

UPVC PVC Window Machine

Aluminum Window Machine

Glass Cutting Machine

Glass Edging Machine

Insulating Glass Machine

Glass lifting machine

Glass Washing Machine

Glass Laminating Machine

Glass Sandblasting Machine

Glass Drilling Machine

CNC Glass Working Center

CNC Non-Metal Cutting Machine

The Other Glass Machinery

Application

Download

News

Contact Us

In today's fast-paced manufacturing environment, efficiency and precision are paramount, especially in industries involving glass processing. The advent of the Automatic Glass Cutting Machine has revolutionized the way businesses approach their workflows. Utilizing cutting-edge technology, these machines not only enhance the speed of production but also significantly improve the accuracy of cuts, reducing waste and minimizing errors. As companies strive to optimize their operations, integrating an Automatic Glass Cutting Machine into their workflow becomes increasingly essential. This guide will explore various strategies for maximizing the potential of these machines, ensuring that your production process is not only

In today's fast-paced manufacturing environment, efficiency and precision are paramount, especially in industries involving glass processing. The advent of the Automatic Glass Cutting Machine has revolutionized the way businesses approach their workflows. Utilizing cutting-edge technology, these machines not only enhance the speed of production but also significantly improve the accuracy of cuts, reducing waste and minimizing errors. As companies strive to optimize their operations, integrating an Automatic Glass Cutting Machine into their workflow becomes increasingly essential. This guide will explore various strategies for maximizing the potential of these machines, ensuring that your production process is not only

Maintaining and troubleshooting your automatic glass cutting machine is essential for maximizing efficiency and minimizing downtime. According to a report by the Glass Association of North America, proper maintenance can extend the lifespan of glass cutting equipment by up to 30%. Regular checks on critical components such as the cutting head, conveyor belts, and pneumatic systems can prevent costly repairs and ensure consistent performance. Utilizing an organized maintenance schedule that includes daily surface checks and monthly deeper inspections can significantly enhance operational reliability.

Maintaining and troubleshooting your automatic glass cutting machine is essential for maximizing efficiency and minimizing downtime. According to a report by the Glass Association of North America, proper maintenance can extend the lifespan of glass cutting equipment by up to 30%. Regular checks on critical components such as the cutting head, conveyor belts, and pneumatic systems can prevent costly repairs and ensure consistent performance. Utilizing an organized maintenance schedule that includes daily surface checks and monthly deeper inspections can significantly enhance operational reliability.