How to Optimize Your Production with CNC Glass Working Centres

In today's highly competitive market, optimizing production processes is crucial for glass manufacturers aiming to enhance efficiency and reduce costs. The adoption of CNC Glass Working Centres has revolutionized the industry, allowing for greater precision and versatility in glass fabrication.

According to a recent report by MarketsandMarkets, the global CNC machine market is expected to reach $100 billion by 2026, driven by the increasing demand for automated solutions in manufacturing.

The integration of CNC technology not only streamlines operations but also minimizes material wastage and reduces production time significantly. As manufacturers seek to leverage these advanced systems, understanding how to effectively utilize CNC Glass Working Centres becomes imperative for maximizing productivity and ensuring high-quality end products.

By implementing optimized practices, businesses can remain competitive in an evolving landscape while meeting the growing demands of the glass industry.

Optimizing CNC Glass Cutting Speed for Increased Production Efficiency

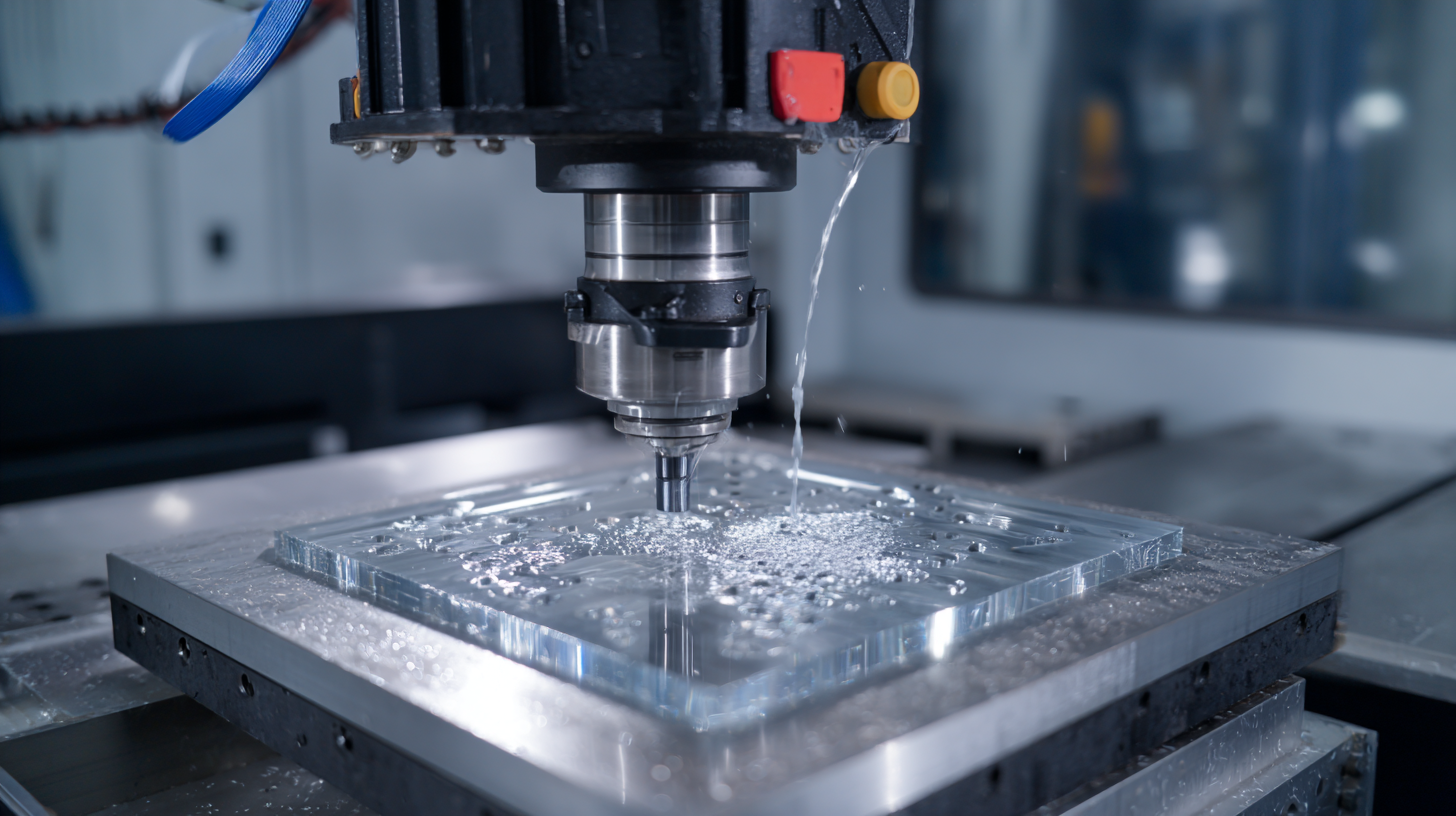

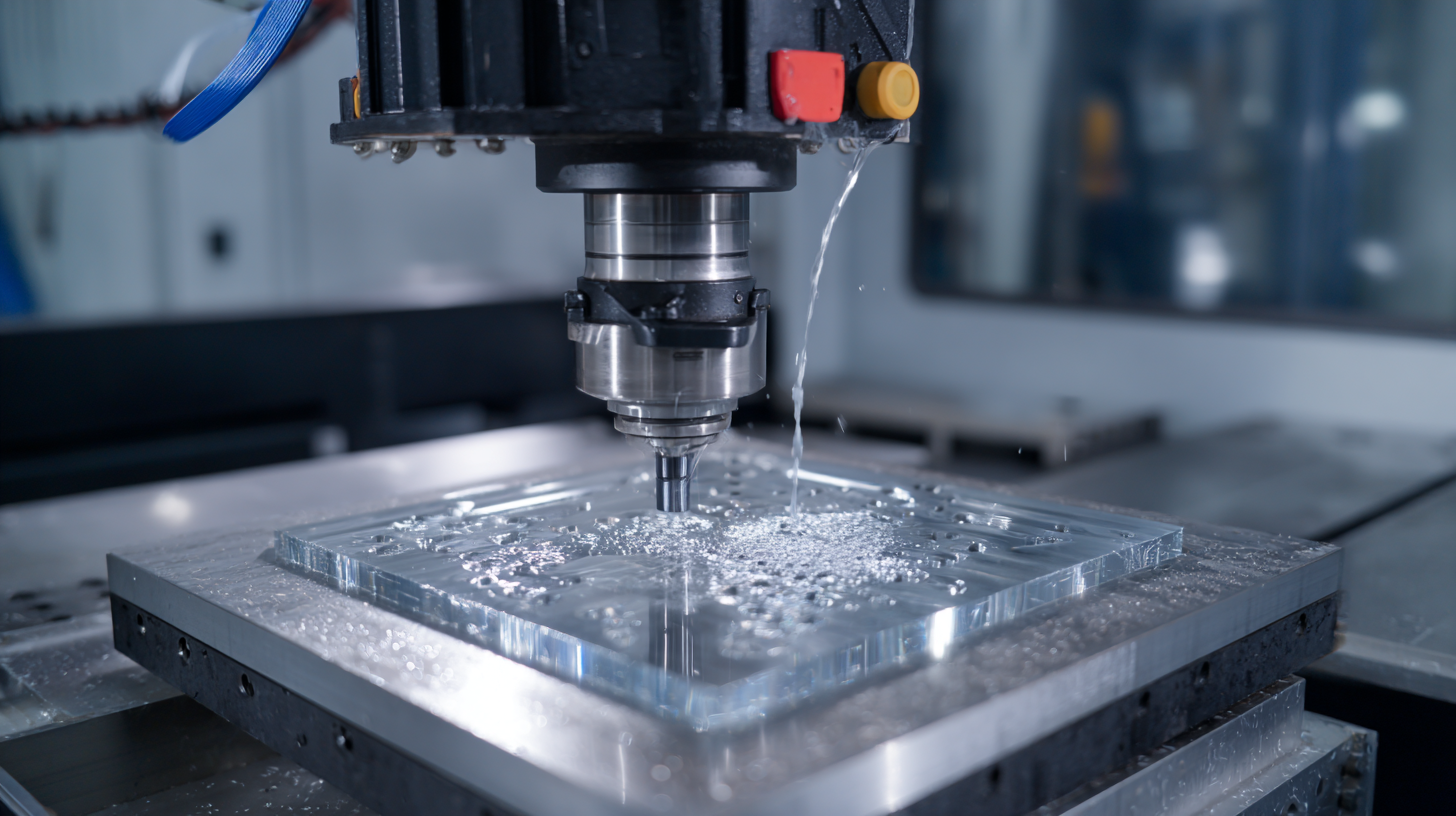

Optimizing CNC glass cutting speed is crucial for enhancing production efficiency in glass manufacturing. By streamlining the cutting process, manufacturers can reduce turnaround times and meet increasing market demands. One effective strategy is to regularly calibrate and maintain CNC machines to ensure they operate at peak performance. This includes checking the cutting tools, optimizing the feed rates, and adjusting the cutting parameters based on the glass thickness and type.

Moreover, implementing advanced programming techniques can significantly impact cutting speed. For example, using software that allows for simulation of the cutting process can help identify the most efficient paths and reduce material waste. Additionally, incorporating automation and real-time monitoring systems can further elevate production capabilities. By analyzing performance data, manufacturers can make informed adjustments to their operations, ultimately speeding up the glass cutting process and improving overall productivity.

Production Efficiency with CNC Glass Cutting Speed

Enhancing Accuracy in CNC Glass Processing: Best Practices and Technologies

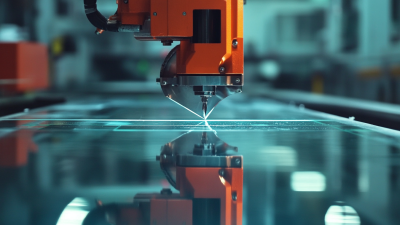

When it comes to CNC glass processing, enhancing accuracy is paramount to achieving high-quality results. The integration of advanced technologies, such as laser cutting and computer-aided design (CAD) software, can significantly enhance precision in glass working. These technologies allow for intricate designs and specifications that manual processing cannot achieve, ultimately leading to a more efficient workflow.

Tips: Regularly calibrate your CNC machines to maintain optimal accuracy. Even minor deviations can impact the final product, so implementing a routine calibration schedule can help mitigate errors. Furthermore, using high-quality glass materials will not only improve the end result but also reduce wear and tear on your equipment.

In combination with these technologies, adopting best practices is essential. Keeping your workspace clean and organized can help prevent contamination of glass surfaces, which can compromise precision. Additionally, training staff on the latest techniques and safety measures effectively ensures that everyone is equipped to handle machinery properly, further enhancing overall productivity and accuracy in CNC glass processing.

Cost-Effective Material Utilization in CNC Glass Working Centres

Cost-effective material utilization is crucial for businesses utilizing CNC glass working centres. According to a recent industry report by the Glass Manufacturing Industry Council, optimizing material use can reduce waste by up to 35%, significantly lowering production costs. This efficiency is not only beneficial for the bottom line but also contributes to sustainability goals, minimizing the ecological footprint of glass production.

To achieve greater material efficiency, companies should focus on advanced software solutions that offer precise cutting path algorithms, maximizing yield from each glass sheet. Utilizing nesting software can ensure that every piece of material is used effectively, cutting down on excess while maintaining high-quality output.

**Tips for Cost-Effective Material Utilization:**

- Regularly evaluate your CNC settings to ensure optimal performance; minor adjustments can lead to better material yield.

- Train operators on best practices for glass handling and processing to reduce accidental breakage and waste.

- Implement a feedback loop where production data is analyzed to continuously fine-tune processes and identify areas for improvement.

How to Optimize Your Production with CNC Glass Working Centres - Cost-Effective Material Utilization in CNC Glass Working Centres

| Material Type |

Thickness (mm) |

Cutting Speed (m/min) |

Waste (%) |

Production Cost ($/m²) |

| Float Glass |

4 |

40 |

15 |

20 |

| Laminated Glass |

6 |

30 |

10 |

35 |

| Tempered Glass |

8 |

25 |

12 |

45 |

| Insulated Glass |

12 |

20 |

8 |

50 |

| Mirror Glass |

5 |

35 |

14 |

30 |

Integration of Automation in CNC Glass Production: Benefits and Challenges

The integration of automation in CNC glass production presents numerous benefits, significantly enhancing productivity and precision. Automated systems can operate continuously, reducing the downtime associated with manual processes. This allows for higher volume production and consistent output quality, essential for meeting the increasing demand in various industries, such as architecture and automotive. Additionally, automation minimizes human errors, ensuring that dimensions and finishes remain exact, which is crucial in glassworking where tolerances are often tight.

However, the transition to automated CNC glass working centres is not without challenges. Initial costs for automation technologies can be substantial, which may deter smaller operations from adopting these advancements. Furthermore, there is often a steep learning curve involved, as workforce training is necessary to effectively manage and troubleshoot automated systems. Companies must also contend with potential maintenance issues and the need for software updates, which can disrupt production if not addressed promptly. Balancing these factors is essential for businesses looking to leverage the advantages of automation while mitigating its associated risks.

Leveraging Data Analytics for Continuous Improvement in Glass Working Operations

Data analytics is transforming the glass manufacturing industry by providing insights that foster continuous improvement. By leveraging real-time data, manufacturers can identify inefficiencies and enhance production processes. For instance, the integration of data reconciliation methods addresses sensor measurement errors in glass-melting furnaces, enabling operators to optimize the furnace performance significantly. These insights allow for better decision-making and greater control over production parameters, ultimately leading to higher efficiency and reduced waste.

Moreover, the development of soft sensors for measuring glass viscosity exemplifies how data-driven approaches can refine quality control in glass container manufacturing. Such innovations reduce reliance on traditional trial-and-error methods by providing precise measurements that inform adjustments in real-time. The shift toward predictive maintenance, powered by analytics, further illustrates the potential for minimizing machine downtime. By continuously monitoring operational data, manufacturers can proactively service equipment, thereby improving overall productivity and ensuring a more sustainable glass production process.

Home

About Us

Products

UPVC PVC Window Machine

Aluminum Window Machine

Glass Cutting Machine

Glass Edging Machine

Insulating Glass Machine

Glass lifting machine

Glass Washing Machine

Glass Laminating Machine

Glass Sandblasting Machine

Glass Drilling Machine

CNC Glass Working Center

CNC Non-Metal Cutting Machine

The Other Glass Machinery

Application

Download

News

Contact Us