How to Optimize Your Glass Grinding Machine for Maximum Efficiency

In the competitive landscape of the glass manufacturing industry, the efficiency of your equipment can significantly impact productivity and profitability. According to a recent industry report by the Glass Manufacturing Industry Council, optimizing glass grinding machines can lead to a potential reduction in operational costs by up to 30%. With increasing demands for precision and quality, the glass grinding process plays a crucial role in ensuring superior product output.

By implementing specific strategies to enhance the performance of your glass grinding machine, manufacturers not only improve throughput but also extend the lifespan of their machinery. This blog will explore essential optimization techniques tailored for glass grinding machines, enabling businesses to achieve maximum efficiency while maintaining high standards for quality.

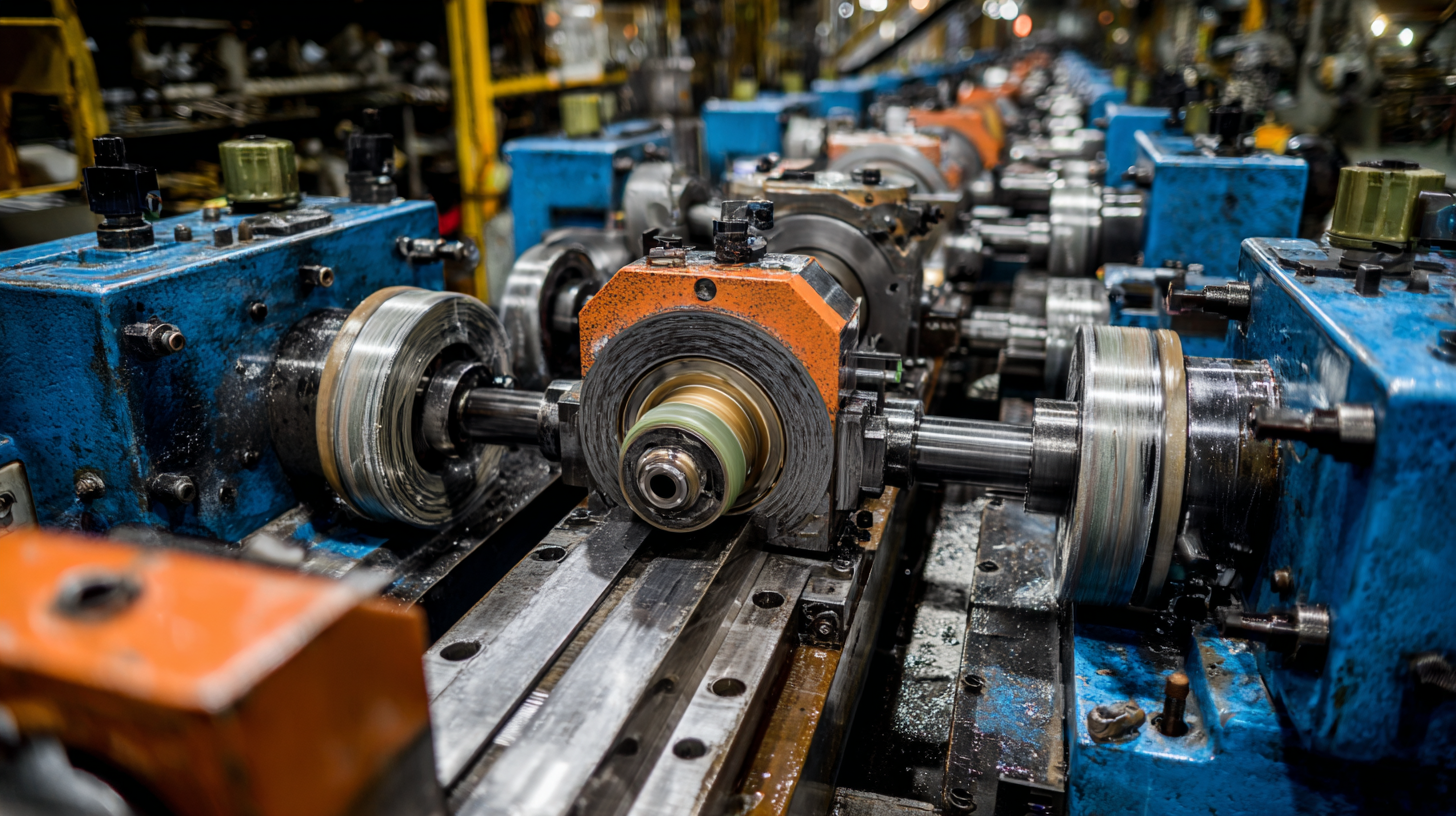

Essential Components of Glass Grinding Machines for Optimal Performance

When optimizing your glass grinding machine for maximum efficiency, understanding the essential components is crucial. The heart of any glass grinding machine is the grinding wheel, which must be selected based on the material of the glass and the desired finish. A well-chosen grinding wheel not only enhances the overall performance but also reduces wear and tear, leading to less frequent replacements. Additionally, the cooling system plays a pivotal role; proper cooling prevents overheating, ensuring that both the glass and the machine remain in optimal condition during operation.

Another critical element is the feed mechanism. A reliable feed mechanism ensures consistent and controlled movement of the glass piece towards the grinding surface, allowing for accurate and efficient grinding. Integrating automation into this component can significantly reduce human error and increase productivity. Lastly, regular maintenance of all these components, including the alignment of the grinding wheel and the calibration of the feed rates, is essential for sustaining optimal performance. By focusing on these fundamental parts, you can effectively enhance the efficiency and longevity of your glass grinding machine.

Optimization of Glass Grinding Machines: Efficiency Metrics

Key Maintenance Practices to Enhance Grinding Efficiency

To ensure that your glass grinding machine operates at peak efficiency, regular maintenance is crucial. One of the key practices is to keep the grinding tools and components clean. Dust and debris can accumulate over time, leading to inefficient grinding and impacting the quality of the finished product. Implementing a routine cleaning schedule helps prevent this buildup, ensuring that your machinery runs smoothly and effectively.

Another important aspect of maintenance is the inspection and replacement of worn parts. Grinding machines like any other equipment, face wear and tear that can hinder their performance. Regularly checking the grinding belts, wheels, and coolant systems can identify potential issues before they escalate into costly repairs. Moreover, timely replacement of these components not only improves efficiency but also extends the lifespan of the machine, resulting in more reliable operation.

Finally, calibrating the machine settings is essential for optimum performance. Ensuring that the speed, pressure, and alignment of the grinding wheels are correctly set can make a significant difference in the overall efficiency of the grinding process. By taking the time to adjust these settings according to the specific requirements of the glass being processed, operators can see substantial improvements in both productivity and quality.

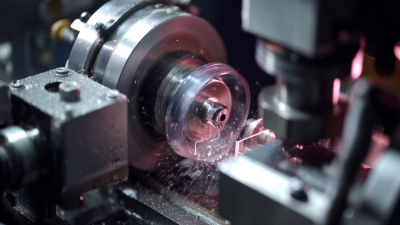

Techniques for Adjusting Grinding Parameters for Better Results

Optimizing your glass grinding machine requires careful adjustment of several key parameters that directly influence efficiency and output quality. One of the most critical factors is the grinding wheel speed. Increasing the RPM can significantly enhance material removal rates, but it’s essential to balance this with the type of glass being processed. Softer glasses may tolerate higher speeds, while harder materials may require slower speeds to prevent excessive wear on the grinding wheel and maintain a smooth finish.

In addition to wheel speed, feed rate also plays a vital role in the grinding process. Adjusting the feed rate to a suitable level—neither too fast nor too slow—can help achieve the desired finish while maximizing efficiency. A slower feed rate enables better control and a finer finish, while a faster rate can boost productivity when dealing with less demanding glass types. Additionally, ensuring the correct coolant flow during grinding not only minimizes heat buildup but also prolongs the lifespan of both the grinding wheel and the machine itself, ultimately leading to better performance and results.

Utilizing Technology to Monitor and Improve Grinding Processes

In the glass manufacturing industry, optimizing grinding processes is crucial for maximizing efficiency and minimizing waste. By leveraging advanced technology, manufacturers can monitor and refine their grinding operations, leading to significant improvements in productivity. A recent report by the Glass Manufacturing Industry Council indicates that companies implementing real-time monitoring solutions have experienced up to a 20% reduction in manufacturing costs, showcasing the immense potential of technological integration.

To enhance the grinding process, consider adopting vibration monitoring systems that can detect deviations early on. This proactive approach not only reduces downtime but also prolongs the life of the grinding equipment, which can lead to savings of approximately 15% in maintenance costs, as noted by the Society of Manufacturing Engineers.

Moreover, utilizing data analytics tools can provide insights into operational inefficiencies. By analyzing historical data, manufacturers can identify patterns that may indicate suboptimal settings or equipment performance. Maintenance scheduling can be optimized, enabling companies to avoid costly production delays and ensuring seamless operations. Aim to invest in software that visualizes grinding parameters and performance metrics, keeping your operations agile and responsive to changing demands.

Common Mistakes to Avoid in Glass Grinding Operations for Peak Efficiency

When it comes to glass grinding operations, avoiding common mistakes can significantly enhance efficiency and productivity. One of the most prevalent errors is neglecting proper machine maintenance. Regular checks and timely replacements of worn-out parts ensure that the grinding machine operates at optimal performance levels. Additionally, failing to calibrate the grinding parameters, such as speed and pressure, can lead to inconsistencies in the glass finish, ultimately affecting the quality of the final product.

Another critical mistake to avoid is using inappropriate grinding wheels for specific glass types. Each glass variant requires a particular wheel composition and grit size to achieve the desired finish without causing breakage or excessive wear on the machine. Furthermore, not training operators on best practices can result in inefficient practices that waste time and resources. Proper training ensures that team members understand the nuances of the equipment, enabling them to make informed adjustments that extend the machine's lifespan and improve overall output quality.

Home

About Us

Products

UPVC PVC Window Machine

Aluminum Window Machine

Glass Cutting Machine

Glass Edging Machine

Insulating Glass Machine

Glass lifting machine

Glass Washing Machine

Glass Laminating Machine

Glass Sandblasting Machine

Glass Drilling Machine

CNC Glass Working Center

CNC Non-Metal Cutting Machine

The Other Glass Machinery

Application

Download

News

Contact Us