7 Best Techniques to Maximize Efficiency with Cnc Glass Working Centre

In today's fast-paced manufacturing environment, maximizing efficiency is paramount, especially when working with advanced machinery like the CNC Glass Working Centre. As technology continues to evolve, so too do the techniques that allow artisans and manufacturers to enhance their productivity and output quality. This blog will explore seven of the best techniques designed specifically for optimizing workflows when using the CNC Glass Working Centre. From selecting the right materials and tools to mastering programming and automation, these strategies will not only streamline operations but also lead to superior results in glass fabrication. Whether you are a seasoned professional or just starting in the industry, understanding these techniques will empower you to make the most out of your CNC Glass Working Centre and elevate your production capabilities.

Essential CNC Glass Working Techniques for Enhanced Productivity

In the rapidly evolving world of glass manufacturing, adopting essential CNC glass working techniques can significantly enhance productivity. The integration of these advanced methods not only streamlines processes but also ensures high-quality outputs, meeting the growing demands of the global market. As industries shift towards high-quality development, focusing on efficiency is paramount for staying competitive.

One effective tip is to implement real-time monitoring systems within your CNC glass working centers. By utilizing advanced sensors and data analytics, manufacturers can track production metrics and identify areas for improvement instantly. This proactive approach helps in minimizing downtime and optimizing resource allocation, contributing to overall productivity.

Another technique involves implementing comprehensive employee training programs. Well-trained staff can operate CNC machines more efficiently and troubleshoot issues quickly, reducing delays caused by human error or equipment malfunctions. Regular workshops and skill enhancement sessions not only boost morale but also foster a culture of continuous improvement, which is essential for leveraging the full potential of CNC technology in glass working.

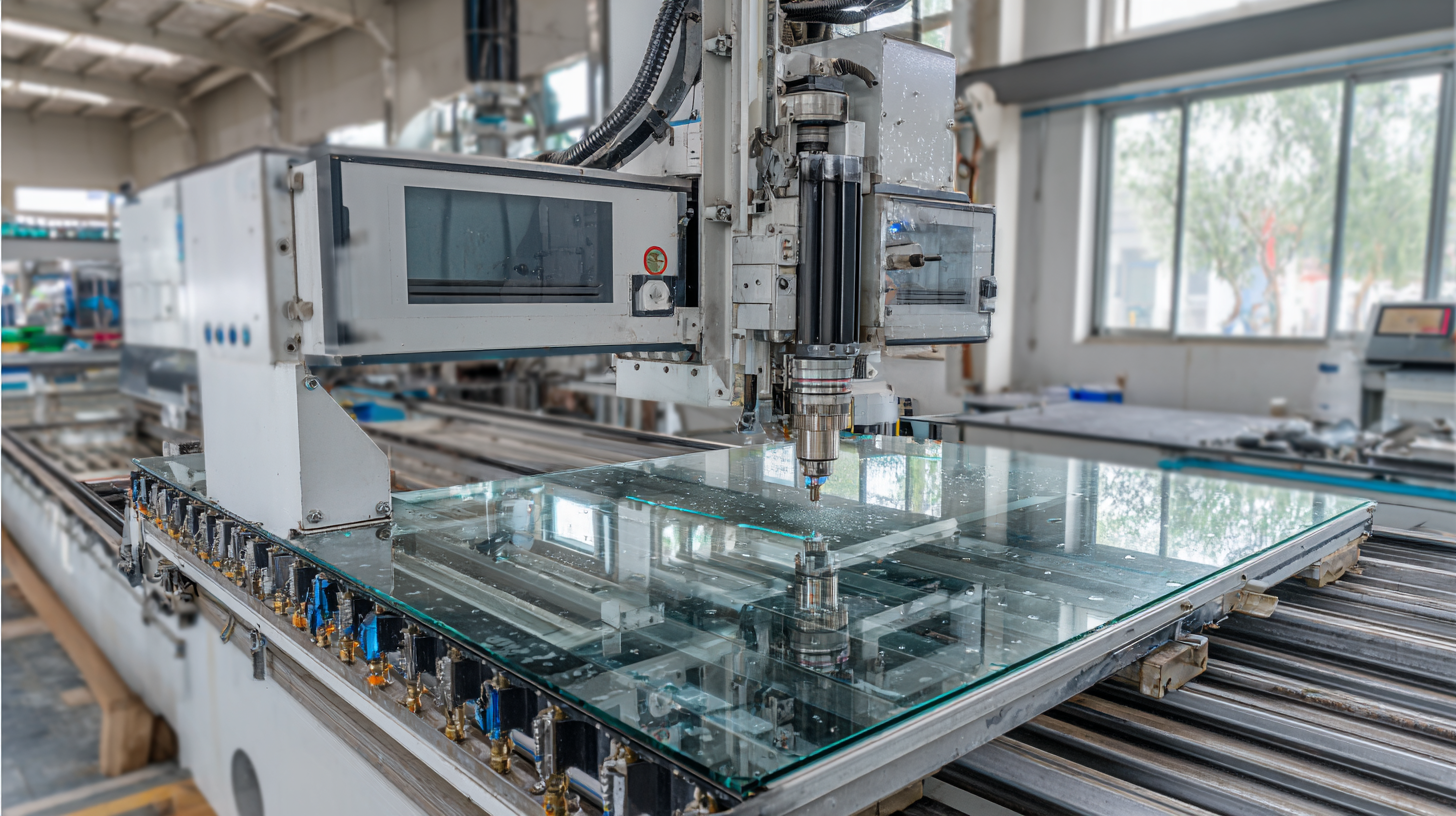

Understanding the Key Components of CNC Glass Working Centers

CNC glass working centers have revolutionized the way glass materials are handled in manufacturing. Understanding the key components of these centers is crucial for maximizing efficiency. The key components include the cutting head, CNC control system, and the cooling system, each playing a critical role in the precision and durability of the glass products. Moreover, the integration of advanced software enhances the machine's flexibility, allowing for various designs and patterns to be easily produced.

Recent industry insights, particularly from a visit to a major technology company, highlight the importance of these components. Executives emphasize that the sophistication of their CNC glass working centers has significantly streamlined production processes, granting them a competitive edge. The ability to adapt quickly to market demands while ensuring high-quality output is a testament to the efficacy of modern CNC systems in glassworking. By focusing on these essential components, manufacturers can not only improve their operational efficiency but also enhance the overall value of their glass products.

Maximize Efficiency with CNC Glass Working Centers

Best Practices for Tool Selection and Maintenance in CNC Operations

In CNC glass working operations, the selection and maintenance of tools are crucial for maximizing efficiency and productivity. According to a study by the Manufacturing Institute, proper tool selection can increase production speeds by up to 30% while simultaneously reducing waste by nearly 20%. This highlights the importance of choosing the right tools for cutting, engraving, or shaping glass, as improper selections can lead to quicker wear and increased machining times.

Moreover, regular maintenance of CNC tools is vital for sustaining operational efficiency. A report from the Society of Manufacturing Engineers indicates that organizations practicing proactive tool maintenance experience a 25% reduction in machine downtime. Key maintenance practices include routine inspections, proper storage, and timely replacements of worn tools.

Implementing a structured tool maintenance schedule not only preserves the integrity of the equipment but also extends the lifespan of the tools, ultimately contributing to a more cost-effective CNC operation. By prioritizing these best practices, manufacturers can enhance their overall efficiency in glass working applications.

Optimizing Workflow: Layout and Design Tips for CNC Glass Workspaces

In the realm of CNC glass working, optimizing workflow is crucial for maximizing efficiency. A well-thought-out layout and design can significantly enhance productivity. Reports from industry studies suggest that a strategic workspace configuration can improve operational efficiency by up to 30%. This includes arranging tools, materials, and machinery in a systematic manner that minimizes movement and maximizes accessibility.

Furthermore, the incorporation of advanced technologies, such as automated material handling and real-time monitoring systems, can streamline processes in a CNC glass workshop. A focus on ergonomics can also lead to improved worker satisfaction and reduced downtime. As cities like Shanghai reimagine industrial spaces, there is a growing emphasis on preserving industrial heritage while adapting it for modern uses, reflecting a parallel in the glassworking industry where innovation meets tradition. Optimizing the workspace of a CNC glass working centre not only enhances productivity but also revitalizes the craftsmanship that defines the industry.

Data-Driven Approaches: Utilizing Software for Efficiency in CNC Glass Processing

In the world of CNC glass processing, data-driven approaches play a critical role in enhancing efficiency. By leveraging advanced software solutions, businesses can optimize their workflow and reduce waste. Integrating software with CNC machines allows for real-time monitoring and analysis, leading to informed decision-making that enhances productivity.

One effective tip is to utilize predictive analytics to anticipate equipment maintenance needs. This proactive approach minimizes downtime and keeps production on track. Additionally, implementing automation software can streamline routine tasks, allowing operators to focus on more complex processes that require human intervention.

It's also beneficial to adopt a comprehensive data management system that collects and analyzes performance metrics over time. This can help identify trends and areas for improvement, enabling operators to fine-tune their techniques and maximize output. By embracing these data-driven strategies, businesses can not only boost efficiency but also maintain high-quality standards in CNC glass working.

Home

About Us

Products

UPVC PVC Window Machine

Aluminum Window Machine

Glass Cutting Machine

Glass Edging Machine

Insulating Glass Machine

Glass lifting machine

Glass Washing Machine

Glass Laminating Machine

Glass Sandblasting Machine

Glass Drilling Machine

CNC Glass Working Center

CNC Non-Metal Cutting Machine

The Other Glass Machinery

Application

Download

News

Contact Us