Why Invest in a CNC Glass Cutting Machine for Your Business Efficiency

In today’s competitive manufacturing landscape, efficiency and precision are paramount, particularly in industries dealing with glass products. The advent of technology has transformed traditional glass cutting methods into advanced automated processes, prominently featuring the CNC Glass Cutting Machine. According to industry reports, the CNC machine market is projected to grow significantly, with an expected compound annual growth rate (CAGR) of over 6% from 2023 to 2030. This rapid growth underscores the increasing reliance on automation for enhanced productivity and reduced operational costs.

Investing in a CNC Glass Cutting Machine not only streamlines production lines but also significantly enhances precision and accuracy. Recent studies indicate that businesses utilizing CNC technology experience a reduction in waste material by up to 30%, while also achieving tighter tolerances that manual cutting cannot replicate. By adopting such advanced machinery, companies can respond swiftly to market demands, reduce lead times, and ultimately boost profitability. As the industry continues to evolve, integrating a CNC Glass Cutting Machine stands out as a strategic investment for businesses aiming to maximize operational efficiency and maintain a competitive edge in the market.

Benefits of CNC Glass Cutting Machines for Business Operations

CNC glass cutting machines have become indispensable tools in modern manufacturing settings, significantly enhancing operational efficiency and precision. According to a report by Research and Markets, the global CNC machine tools market is expected to reach $93.01 billion by 2025, reflecting a compound annual growth rate (CAGR) of 6.8%. This surge is primarily driven by increasing automation in manufacturing processes, underscoring the importance of adopting advanced technologies like CNC for glass cutting.

The benefits of CNC glass cutting machines extend beyond mere automation. They offer exceptional accuracy, allowing businesses to reduce waste and optimize material usage. A study published in the Journal of Manufacturing Science and Engineering highlights that CNC technology can improve cutting precision by up to 20% compared to traditional methods. In environments where margins are slim, such enhancements can translate to significant cost savings. Furthermore, the automation involved in CNC cutting systems minimizes human error and reduces labor costs, making them a more efficient choice for glass fabrication operations.

Additionally, the versatility of CNC glass cutting machines allows manufacturers to streamline workflows. With their ability to handle complex designs and large volumes, these machines can adapt to various production needs without sacrificing speed. According to a survey by the International Glass Association, companies utilizing CNC technology reported a 30% increase in production capacity while maintaining high-quality standards. This adaptability not only boosts productivity but also positions businesses to quickly respond to changing market demands, further solidifying the case for investment in CNC glass cutting machines.

Key Features to Look for in a CNC Glass Cutting Machine

When considering a CNC glass cutting machine, several key features can significantly enhance your business efficiency. First and foremost, precision is vital. Look for machines that offer high cutting accuracy and repeatability, as this will reduce waste and ensure that each piece of glass meets the required specifications. Advanced CNC technology with high-resolution encoders can help achieve this level of precision, allowing for intricate designs and complex cuts that manual processes cannot replicate.

Another important feature is the machine’s versatility. A multifunctional CNC glass cutting machine should be able to handle various glass thicknesses and types, including tempered, laminated, and coated glass. This flexibility not only broadens the range of products your business can offer but also enhances operational efficiency by eliminating the need for multiple machines. Additionally, integration with CAD software can simplify the design process, enabling quick adjustments and enabling operators to streamline production workflows.

Finally, consider the ease of use and maintenance. User-friendly interfaces and straightforward programming can significantly reduce training time for staff and minimize the risk of errors. Furthermore, machines designed for easy maintenance can enhance uptime and productivity, allowing your business to operate smoothly without unnecessary delays. Prioritizing these features will ensure that your investment in a CNC glass cutting machine pays off in terms of both efficiency and output quality.

Cost-Effectiveness and ROI of Investing in CNC Technology

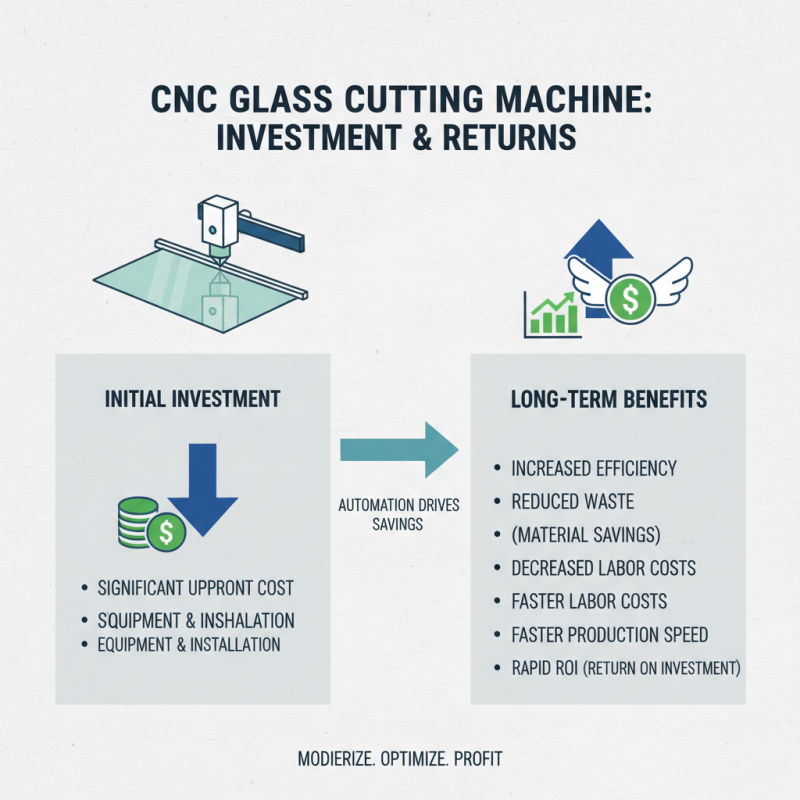

Investing in a CNC glass cutting machine can significantly enhance the cost-effectiveness of a business, especially in industries where precision and efficiency are paramount. The initial expense of acquiring CNC technology may seem daunting, but when analyzed against the backdrop of potential returns, it becomes evident that the investment pays off over time. The automation capabilities of CNC machines reduce labor costs and minimize human error, leading to higher productivity levels. This increase in output not only allows businesses to meet rising demand but also enables them to allocate resources more efficiently.

Moreover, the precision offered by CNC glass cutting machines leads to reduced waste and material costs. By utilizing software-controlled cutting, companies can optimize material usage, ensuring that every piece of glass is cut efficiently, and minimizing scrap. This strategic advantage not only conserves resources but also contributes to overall sustainability efforts. As businesses continue to prioritize eco-friendly practices, the cost savings derived from reduced waste alongside the improved accuracy of cuts adds an appealing layer to the ROI of CNC technology. With operational expenses lowered and production capabilities enhanced, investing in CNC machines becomes a strategic move towards long-term financial health and business growth.

Investment in CNC Glass Cutting Machines - Efficiency and ROI Analysis

This chart represents the operating efficiency of investing in CNC glass cutting machines compared to traditional cutting methods. The data illustrates significant improvements in efficiency, estimated savings, and increased production capabilities, demonstrating the cost-effectiveness and return on investment (ROI) associated with CNC technology.

Improving Precision and Quality in Glass Cutting Processes

Investing in a CNC glass cutting machine can significantly enhance the precision and quality of glass cutting processes in your business. Traditional glass cutting methods often lead to inconsistencies and human error, impacting the final product's quality. CNC technologies leverage advanced software and automation to ensure that each cut is executed with remarkable accuracy, reducing reliance on manual labor and minimizing mistakes.

This precision is essential, especially in industries where exact dimensions and smooth edges are crucial, such as architecture, automotive, and interior design.

Moreover, a CNC glass cutting machine can drastically improve the overall quality of glass products. The ability to program complex designs and intricate patterns allows businesses to meet diverse customer needs without compromising on quality. The clean, precise cuts achieved through CNC technology not only enhance the aesthetic appeal of finished products but also contribute to improved structural integrity.

By integrating cutting-edge machinery into their operations, businesses can not only elevate their product offerings but also establish a competitive edge in the market, ultimately fostering customer satisfaction and loyalty.

Q&A: Common Concerns About CNC Glass Cutting Machine Implementation

When considering the implementation of a CNC glass cutting machine in your business, several common concerns may arise. One of the primary questions involves the initial investment cost. While CNC machines can require a significant upfront expenditure, they often lead to long-term savings through increased efficiency and reduced waste. Investing in automation can drastically cut down labor costs and enhance production speed, allowing businesses to recoup the investment in a relatively short time.

Another concern frequently voiced is the complexity of operation. Many potential users worry that CNC technology may be too complicated for their staff to handle effectively. However, most modern CNC machines come equipped with user-friendly interfaces and comprehensive training support. Additionally, operators can learn to use the system efficiently through hands-on training and tutorials, which facilitates a smoother transition from traditional methods to CNC technology. As businesses adopt these innovative solutions, the learning curve lessens, leading to a more skilled workforce and ultimately boosting overall productivity.

Home

About Us

Products

UPVC PVC Window Machine

Aluminum Window Machine

Glass Cutting Machine

Glass Edging Machine

Insulating Glass Machine

Glass lifting machine

Glass Washing Machine

Glass Laminating Machine

Glass Sandblasting Machine

Glass Drilling Machine

CNC Glass Working Center

CNC Non-Metal Cutting Machine

The Other Glass Machinery

Application

Download

News

Contact Us