Innovative Techniques for Enhancing Glass Edging Machinery Efficiency

In today's competitive manufacturing landscape, the efficiency of Glass Edging Machinery has become a critical focus for companies looking to optimize production processes and reduce operational costs. As the demand for high-quality glass products continues to grow, innovative techniques and technologies are emerging to enhance the performance of edging machinery. This introduction will explore various strategies that can be employed to streamline operations, improve precision, and increase throughput in the glass edging process.

By leveraging advancements in automation, software integration, and machine design, manufacturers can significantly bolster the effectiveness of their Glass Edging Machinery, ultimately leading to superior product quality and heightened customer satisfaction. Understanding these innovative approaches is crucial for industry stakeholders aiming to stay ahead in a fast-evolving market.

Leveraging Automation in Glass Edging Machinery for Improved Performance

In the ever-evolving field of glass processing, leveraging automation in glass edging machinery can significantly enhance performance and efficiency. Incorporating advanced automation technologies allows manufacturers to streamline their operations, reduce labor costs, and minimize human error. For instance, automating the feeding and handling processes can significantly decrease cycle times and enhance precision, resulting in higher quality edges and a smoother final product.

**Tips:** To maximize the benefits of automation, consider integrating real-time monitoring systems that provide instant feedback on machine performance. This can help identify bottlenecks and allow for immediate adjustments, ensuring consistent production rates. Additionally, invest in employee training to empower staff to effectively operate automated systems, which can lead to a smoother transition and better overall outcomes.

Another key aspect of improving machinery efficiency lies in the use of predictive maintenance strategies. By using automation to monitor machine health, manufacturers can preemptively address potential issues before they lead to costly downtimes. Implementing sensors and data analytics can offer insights into wear patterns, enabling timely interventions and extending the lifespan of glass edging equipment.

**Tips:** Regularly update maintenance schedules based on real-time performance data rather than fixed intervals. This approach helps in prioritizing critical repairs and reduces the likelihood of unexpected breakdowns, enhancing overall machinery reliability.

Integrating IoT Solutions to Monitor Glass Edging Efficiency

The integration of IoT solutions in glass edging machinery is revolutionizing the industry by significantly enhancing operational efficiency. According to a report from MarketsandMarkets, the global IoT in manufacturing market is projected to reach $195.3 billion by 2028, growing at a CAGR of 25.4% from 2023. This surge indicates a growing recognition of the transformative potential that smart technologies hold for optimizing production processes, including glass edging.

By implementing IoT sensors, manufacturers can gain real-time insights into the performance of their glass edging machinery. These sensors collect data on variables such as machine speed, tool wear, and energy consumption, allowing operators to make informed decisions that reduce downtime and maintenance costs. The data analytics derived from these IoT solutions can lead to predictive maintenance, which, according to a study by McKinsey, can reduce unplanned outages by up to 50% and increase overall productivity by 20-25%. As manufacturers strive for higher efficiency, embracing IoT technologies in glass edging operations is not just a trend but a necessity for staying competitive in an evolving marketplace.

Efficiency of Glass Edging Machines Before and After IoT Integration

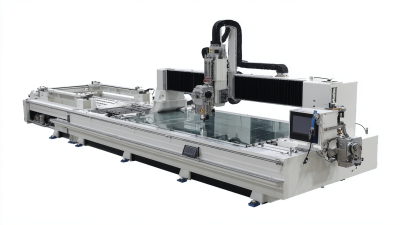

Utilizing Advanced Tooling Techniques to Enhance Precision

The glass fabrication industry is constantly evolving, striving for improved efficiency and precision. Advanced tooling techniques play a crucial role in enhancing glass edging machinery, ensuring that manufacturers can meet the increasing demands for high-quality products. According to a report by Smithers Pira, the global demand for precision glass products is projected to grow by 6.1% annually, underscoring the importance of innovation in machining practices.

One of the key innovations in this realm is the integration of CNC (Computer Numerical Control) technology with diamond tooling. This combination not only increases cutting speeds but also significantly reduces the margin for error, resulting in tighter tolerances. Data from the International Glass Association indicates that companies implementing CNC machinery report a 20-30% reduction in production time, showcasing the tangible benefits of advanced tooling. Additionally, the adoption of multi-functional tools that can perform various edging tasks in a single pass is becoming more prevalent, driving efficiency further while minimizing operational costs.

Moreover, leveraging smart manufacturing techniques and IoT (Internet of Things) connectivity allows for real-time monitoring and adjustments of machinery settings. This adaptability leads to optimized performance levels and reduced downtime. As the industry continues to embrace these technological advancements, manufacturers are not just enhancing the precision of their output but also positioning themselves competitively in a rapidly changing market.

Adopting Predictive Maintenance for Prolonged Machinery Lifespan

Predictive maintenance has emerged as a game-changing strategy in the glass edging industry, significantly enhancing the efficiency and longevity of machinery.

By utilizing advanced monitoring technologies, companies can gather real-time data on machine performance and health.

This proactive approach allows for the identification of potential issues before they escalate into major failures.

By predicting equipment malfunctions, manufacturers can schedule maintenance activities during non-productive hours, minimizing downtime and optimizing operational efficiency.

Predictive maintenance has emerged as a game-changing strategy in the glass edging industry, significantly enhancing the efficiency and longevity of machinery.

By utilizing advanced monitoring technologies, companies can gather real-time data on machine performance and health.

This proactive approach allows for the identification of potential issues before they escalate into major failures.

By predicting equipment malfunctions, manufacturers can schedule maintenance activities during non-productive hours, minimizing downtime and optimizing operational efficiency.

In addition to reducing unexpected breakdowns, predictive maintenance contributes to a more cost-effective operation.

With insights gained from data analytics, organizations can implement maintenance schedules tailored to the unique needs of each piece of machinery.

This targeted strategy not only prolongs the lifespan of the equipment but also ensures that the glass edging machinery operates at peak performance.

As a result, companies can achieve higher production rates and maintain the quality of their output, ultimately leading to increased customer satisfaction and a stronger competitive edge in the market.

Exploring Software Innovations for Real-Time Process Optimization

The integration of software innovations into glass edging machinery is revolutionizing the manufacturing process, enabling real-time optimization that significantly enhances efficiency. Advanced algorithms and machine learning technologies allow for constant monitoring of the edging process, facilitating immediate adjustments to parameters such as speed, pressure, and tool sharpness. This capability not only minimizes errors but also ensures a smoother workflow, thus reducing downtime associated with equipment malfunctions.

In addition to improving operational efficiency, these software solutions generate valuable data analytics that can guide decision-making. By analyzing trends and performance metrics, manufacturers can identify bottlenecks and potential points of failure in their processes. This predictive approach enables proactive maintenance and timely interventions, ensuring that production remains uninterrupted. As a result, manufacturers are likely to experience increased product quality and reduced operational costs, all while keeping pace with the competitive demands of the glass industry.

Home

About Us

Products

UPVC PVC Window Machine

Aluminum Window Machine

Glass Cutting Machine

Glass Edging Machine

Insulating Glass Machine

Glass lifting machine

Glass Washing Machine

Glass Laminating Machine

Glass Sandblasting Machine

Glass Drilling Machine

CNC Glass Working Center

CNC Non-Metal Cutting Machine

The Other Glass Machinery

Application

Download

News

Contact Us