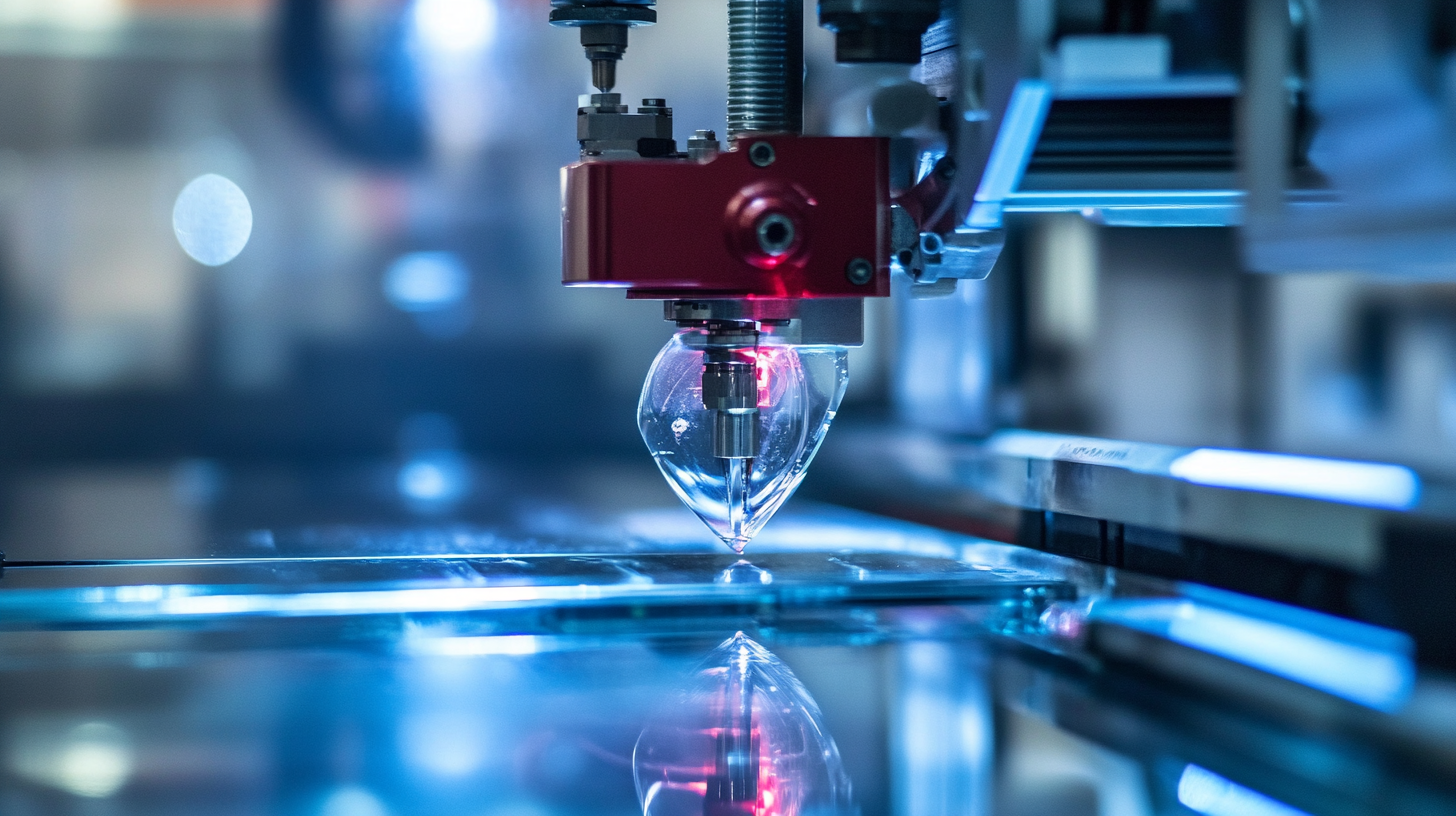

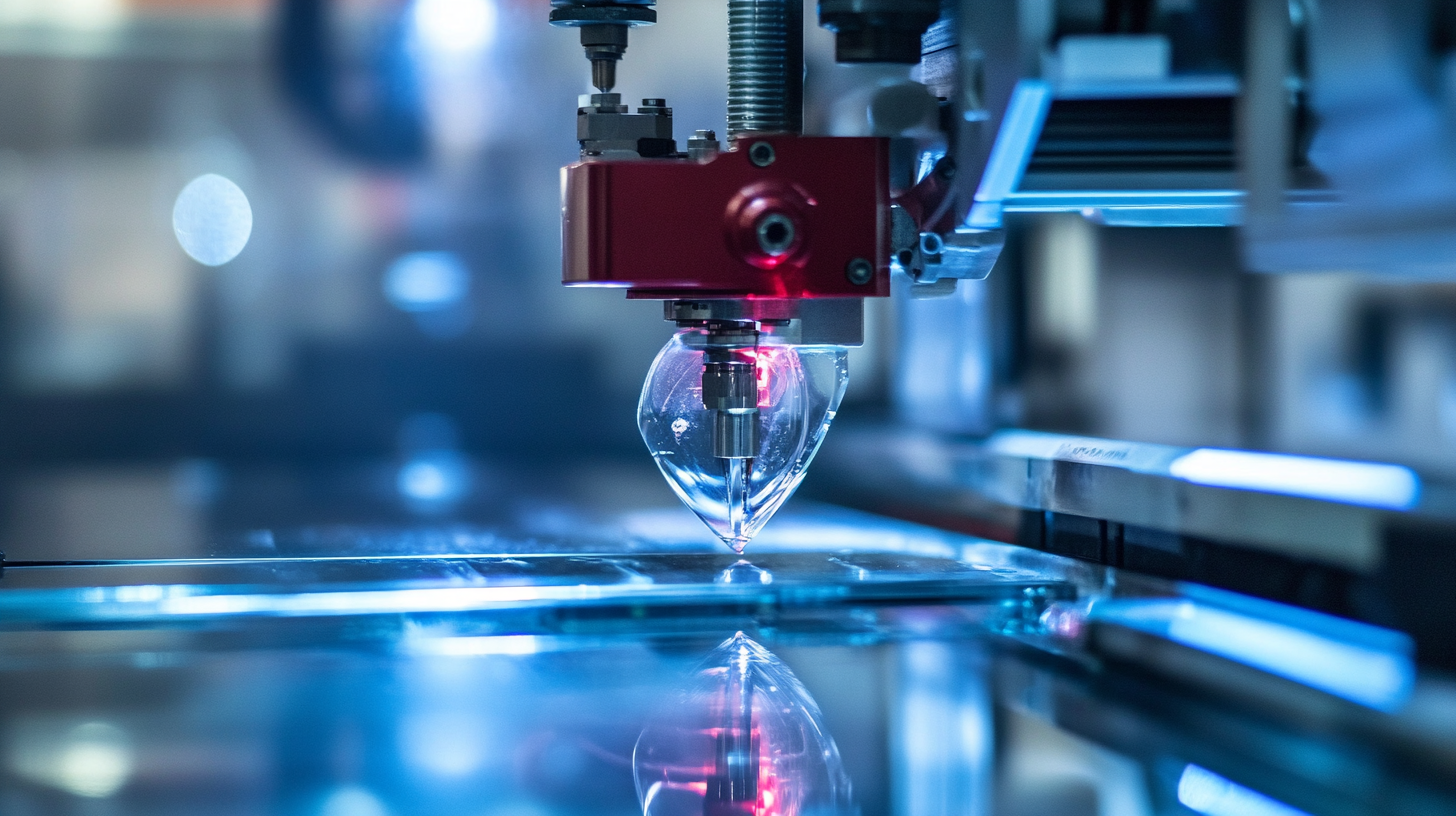

Innovative Solutions for Efficient Production with Best Cnc Glass Drilling Machine

In today's fast-paced manufacturing landscape, the demand for precision and efficiency is paramount, especially in industries that require intricate designs and high-quality glass products. One of the most innovative solutions to enhance production capabilities is the use of a CNC glass drilling machine. These advanced machines not only ensure accurate drilling but also significantly boost overall productivity. However, selecting a high-quality manufacturer for your CNC glass drilling machine is crucial to maximizing its potential benefits. This blog aims to guide you through the essential factors to consider when choosing the best manufacturer, ensuring that you invest in a machine that meets your specific needs and enhances your production processes effectively. Whether you are a seasoned professional or new to the industry, understanding these key aspects will empower you to make informed decisions for your operations.

Understanding the Importance of Choosing a Quality CNC Glass Drilling Machine Manufacturer

Choosing a quality CNC glass drilling machine manufacturer is crucial for ensuring efficiency and precision in production. The global lathe machine market, valued at $25.01 billion in 2018, is projected to reach $57.54 billion by 2032, growing at a compound annual growth rate (CAGR) of 5.6%. This growth underscores the increasing demand for reliable machinery, particularly in industries like glass processing where accuracy is paramount.

When selecting a manufacturer, consider their reputation, the technology they use, and their after-sales support. A top-tier manufacturer will employ advanced CNC technology, ensuring that your drilling tasks are executed with minimal waste and maximum precision.

**Tips:** Regular maintenance is key to prolonging the life of your CNC glass drilling machine. Additionally, investing in training for operators can significantly improve production efficiency. Remember, the right machine partnered with a competent manufacturer can transform your production line and boost overall output.

Key Features to Consider in a CNC Glass Drilling Machine

When selecting a CNC glass drilling machine, there are several key features to consider that can greatly impact production efficiency and quality. First and foremost, the precision of the machine plays a crucial role. Look for models that offer high accuracy in drilling to ensure consistent results and minimize waste. Features such as digital displays and adjustable speed settings can further enhance precision and allow for customization based on specific project requirements.

Another important aspect is the machine's compatibility with various glass types and thicknesses. A versatile CNC glass drilling machine can accommodate a range of materials, from tempered to laminated glass, enabling it to cater to diverse customer needs. Additionally, consider the ease of operation and maintenance. Machines equipped with user-friendly interfaces and automated functions can significantly reduce downtime and training requirements, contributing to smoother production processes.

Lastly, the durability and build quality of the CNC glass drilling machine should not be overlooked. A robust construction will ensure longevity and withstand the demands of high-volume production. Investing in a machine with a strong warranty and reliable customer support can provide peace of mind and protect your investment in the long run. By focusing on these key features, businesses can enhance their production capabilities and maintain a competitive edge in the market.

Innovative Solutions for Efficient Production with Best CNC Glass Drilling Machine

| Feature |

Description |

Importance |

Value |

| Precision |

High accuracy in drilling holes |

Essential for quality craftsmanship |

±0.01 mm |

| Speed |

Rapid drilling capabilities |

Increases production efficiency |

Up to 3000 RPM |

| Automation |

Programmable with CNC |

Reduces manual labor |

Fully automatic |

| Versatility |

Can drill various glass types |

Adapts to different projects |

Compatible with tempered, laminated glass |

| Safety Features |

Inbuilt protection mechanisms |

Minimize risks |

Emergency stops, guards |

| Maintenance |

Ease of upkeep |

Ensures long-term functionality |

User-friendly design |

Evaluating Manufacturer Reputation and Customer Feedback

When considering the acquisition of a CNC glass drilling machine, evaluating the manufacturer’s reputation and customer feedback is crucial for making an informed decision.

According to a report from Freedonia Group, the global demand for glass products is expected to rise by approximately 3.5% annually through 2026, highlighting the importance of investing in quality machinery that can handle increased production needs efficiently.

A trustworthy manufacturer not only ensures that their CNC machines are built to last, but also that they incorporate the latest technological advancements, such as precision drilling capabilities and automated processes that enhance productivity.

Customer feedback plays a significant role in the evaluation process. A survey conducted by the Association for Manufacturing Technology (AMT) revealed that 70% of manufacturers rely on peer reviews and testimonials before making equipment purchases. Engaging with existing users regarding their experiences with specific models can provide insights into machine performance, reliability, and after-sales support.

This data underscores that investing in a CNC glass drilling machine from a reputable manufacturer with positive customer feedback can lead to improved efficiency and reduced downtime in production processes, ultimately contributing to a manufacturer’s bottom line.

Exploring Innovative Technologies in CNC Glass Drilling Machines

The landscape of CNC glass drilling technology is evolving rapidly, driven by innovative solutions that enhance production efficiency. At the heart of these advancements are the latest CNC glass drilling machines, designed to meet the demands of modern industries. These machines utilize advanced computer numerical control systems that allow precise and automated drilling processes, significantly reducing manual labor and the risk of human error. This level of accuracy is essential for producing high-quality glass components that meet rigorous specifications and complex designs.

The landscape of CNC glass drilling technology is evolving rapidly, driven by innovative solutions that enhance production efficiency. At the heart of these advancements are the latest CNC glass drilling machines, designed to meet the demands of modern industries. These machines utilize advanced computer numerical control systems that allow precise and automated drilling processes, significantly reducing manual labor and the risk of human error. This level of accuracy is essential for producing high-quality glass components that meet rigorous specifications and complex designs.

Moreover, the integration of smart technologies, such as IoT and machine learning, into CNC glass drilling machines is transforming how production facilities operate. By enabling real-time monitoring and data analysis, manufacturers can optimize drilling operations, predict maintenance needs, and enhance overall productivity. Innovations like adaptive drilling techniques adjust to varying material properties and thicknesses, ensuring consistent results across diverse applications. As these technologies continue to mature, the glass drilling industry is poised to unlock new levels of efficiency and creativity, paving the way for more complex and customized glass products.

Cost vs. Quality: Making Informed Decisions for Your Production Needs

When it comes to selecting the best CNC glass drilling machine for your production needs, the balance between cost and quality is paramount. According to a recent report from the International Glass Association, companies that prioritize quality in their machinery typically see a 30% increase in overall production efficiency compared to those who opt for lower-cost, inferior machines. This data underscores the importance of investing in quality equipment, as the long-term savings on maintenance and production downtime can far outweigh the initial cost.

Tip: When evaluating different CNC glass drilling machines, consider not only the purchase price but also the potential ROI based on the machine's durability and performance capabilities. A high-quality machine may have a higher upfront cost, but its superior precision and reliability can lead to significant cost savings over time.

Furthermore, manufacturers today face the challenge of integrating innovative solutions with traditional practices. According to a survey by the Glass Manufacturing Industry Council, nearly 60% of industry players believe that incorporating new technologies leads to better product quality and increased competitiveness. Therefore, understanding your specific production needs and aligning them with the right machine features will help in making informed decisions that benefit your bottom line.

Tip: Always consult with industry experts or conduct a thorough market analysis before making a purchase. Engaging with current users of the machines can provide valuable insights that help in making the most informed choice for your production processes.

Home

About Us

Products

UPVC PVC Window Machine

Aluminum Window Machine

Glass Cutting Machine

Glass Edging Machine

Insulating Glass Machine

Glass lifting machine

Glass Washing Machine

Glass Laminating Machine

Glass Sandblasting Machine

Glass Drilling Machine

CNC Glass Working Center

CNC Non-Metal Cutting Machine

The Other Glass Machinery

Application

Download

News

Contact Us

The landscape of

The landscape of