Innovative Solutions for Your CNC Glass Cutting Machine Needs

In the rapidly evolving world of manufacturing, precision and efficiency have become paramount, particularly in the glass industry where the demand for quality CNC Glass Cutting Machines continues to soar. According to a recent report by MarketsandMarkets, the global CNC machine market is projected to reach USD 100 billion by 2025, growing at a CAGR of 6.4%. This growth underscores the increasing reliance on advanced technology for tasks that require meticulous precision, such as glass cutting.

Selecting a high-quality manufacturer is crucial, as the performance of a CNC Glass Cutting Machine directly impacts production efficiency and product quality. In this blog, we will explore innovative solutions to meet your unique CNC glass cutting needs, providing insights on how to identify and collaborate with top-tier manufacturers in the industry. Whether you are upgrading your existing machinery or investing in new equipment, understanding these factors will empower you to make informed decisions that enhance your operational capabilities.

Exploring Alternative Materials for Enhanced CNC Glass Cutting Performance

When it comes to enhancing the performance of CNC glass cutting machines, exploring alternative materials can lead to remarkable improvements. The integration of advanced composite materials offers a unique advantage, allowing for sharper cutting edges and increased durability. These materials not only extend the lifespan of the cutting tools but also reduce the frequency of replacements, ultimately cutting down operational costs.

Tip: Always consider the material compatibility with your CNC machine. Testing different types of composite materials can provide insights into their performance variations, enabling you to choose the best option that meets your specific cutting needs.

Additionally, advancements in coatings and surface treatments can significantly enhance the efficiency of glass cutting processes. Specialized coatings reduce friction and wear, allowing for smoother cuts and less heat generation during operation. This not only results in cleaner edges but also minimizes the risk of glass breakage, ensuring higher quality outputs.

Tip: Regularly evaluate the performance of your cutting tools and stay informed about the latest innovations in coatings. Adopting newer technologies can keep your CNC glass cutting operations at the forefront of efficiency.

Cutting Edge Technologies: Innovations Transforming CNC Glass Cutting Machines

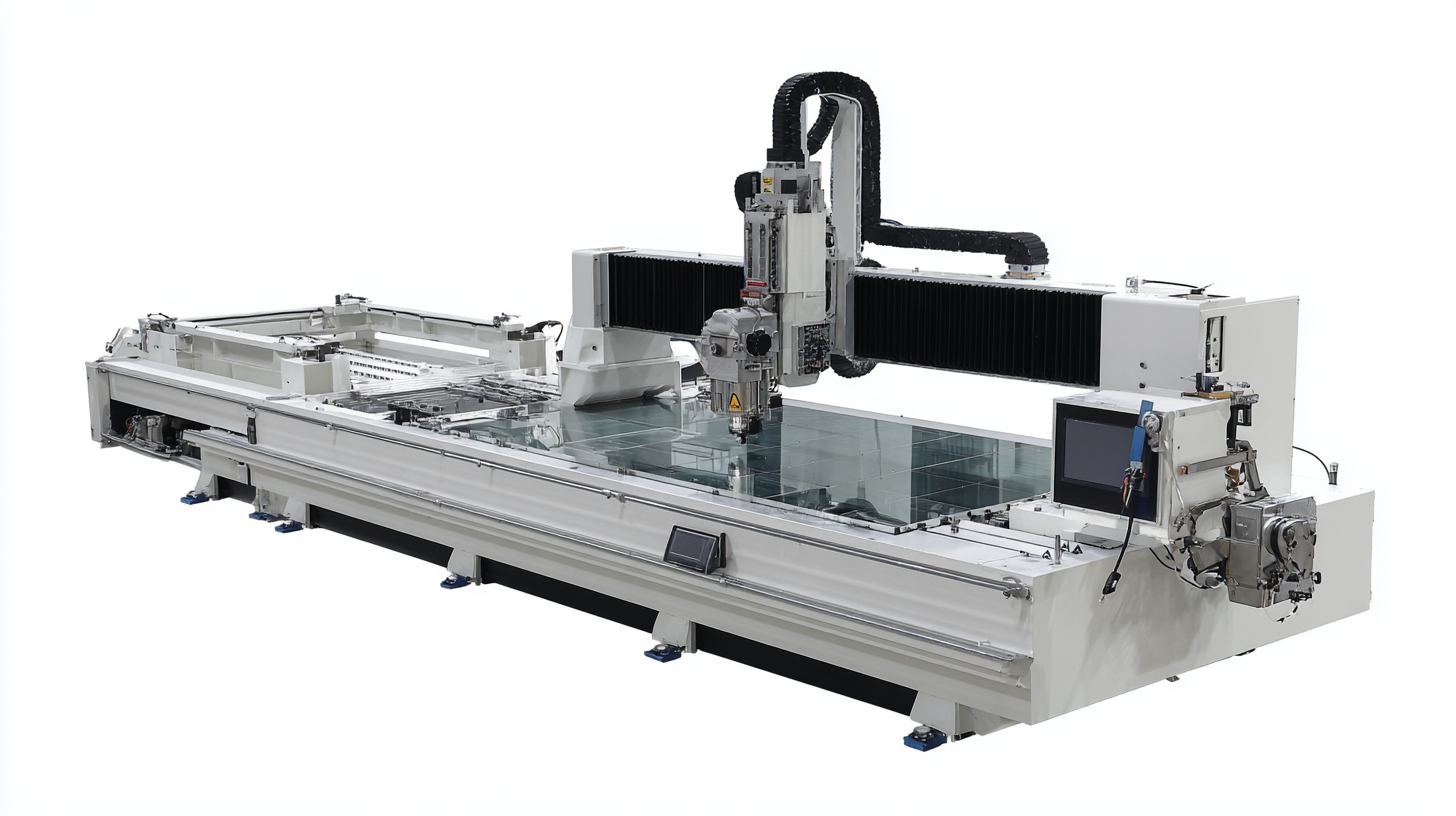

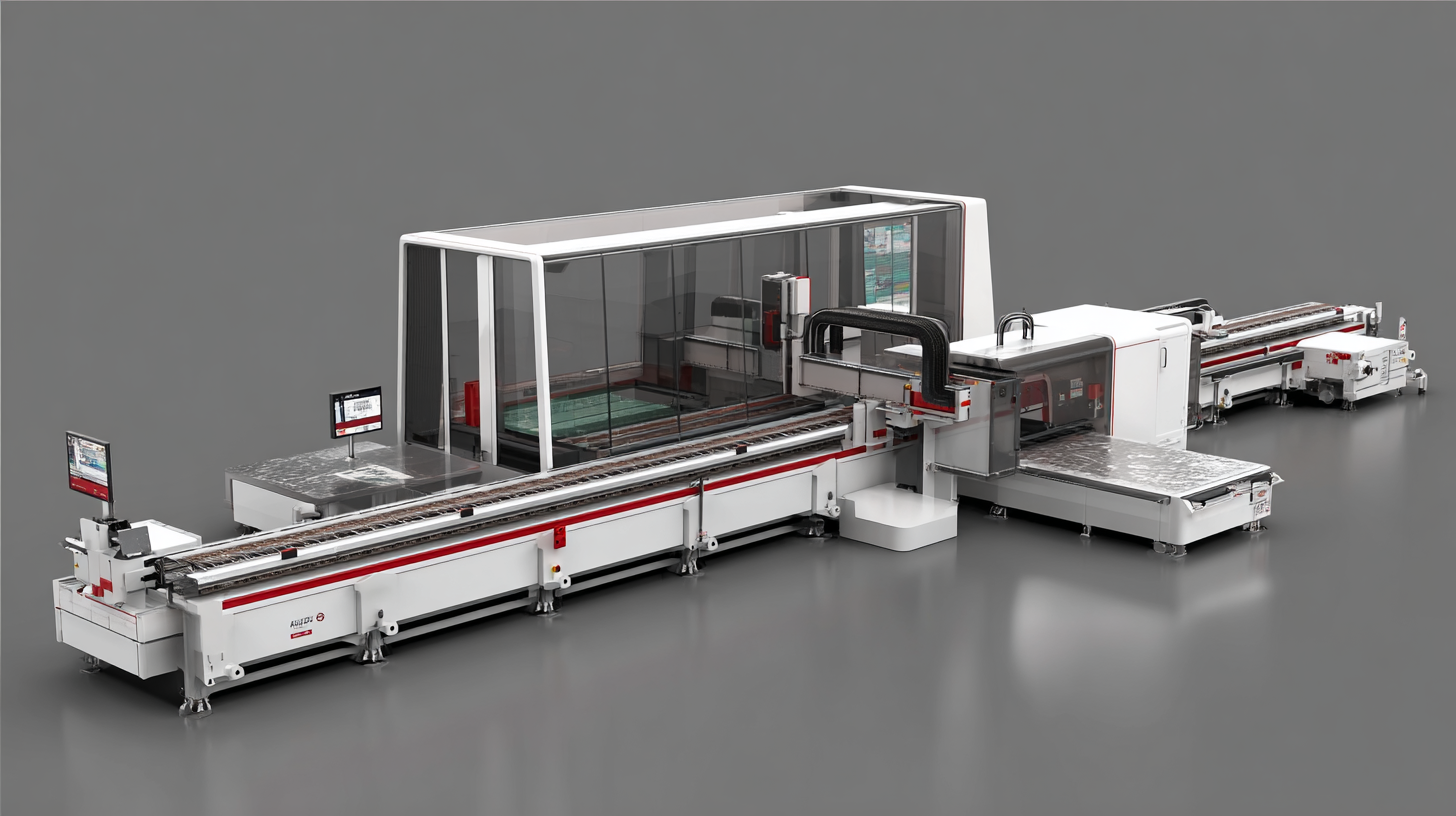

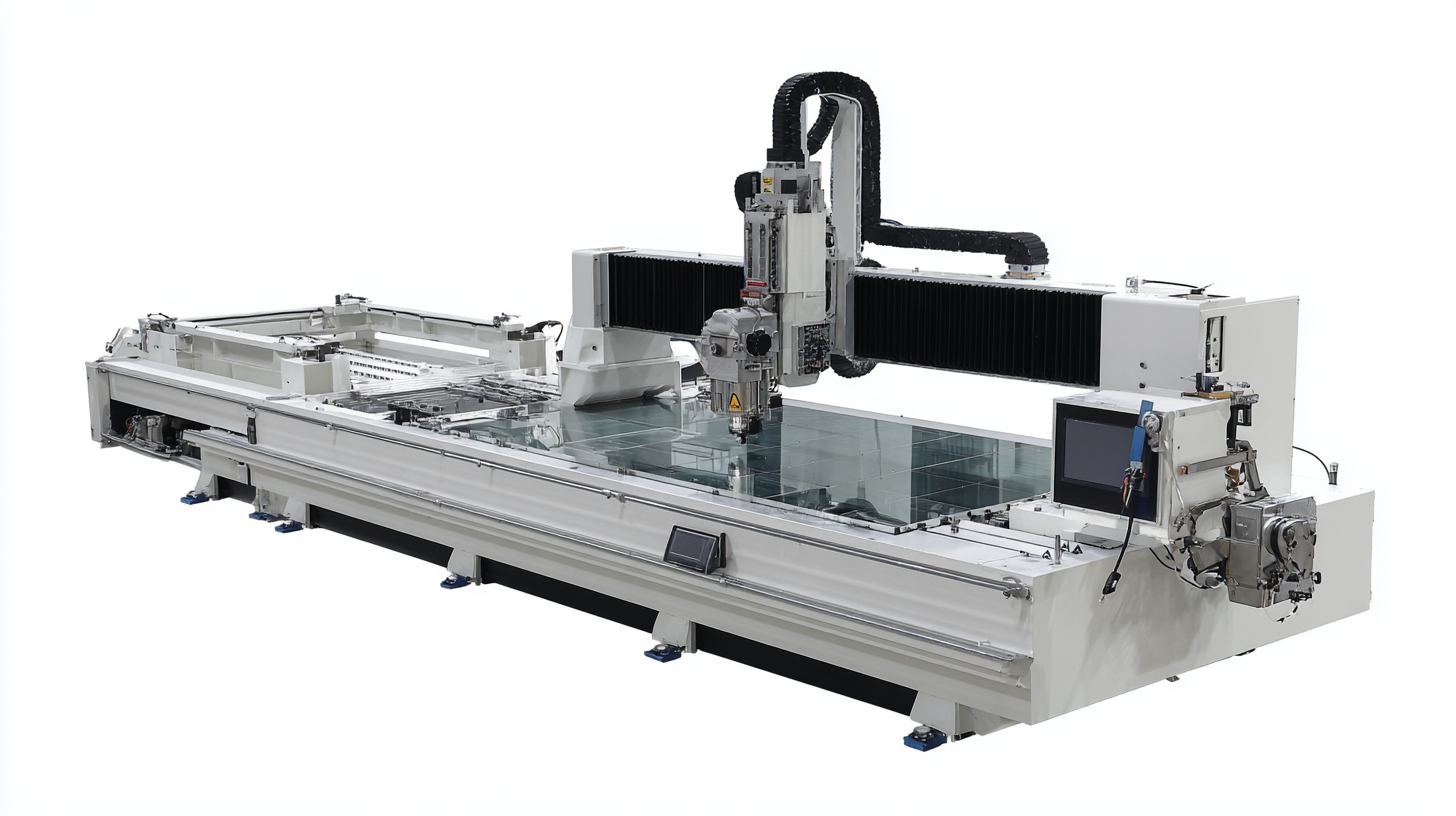

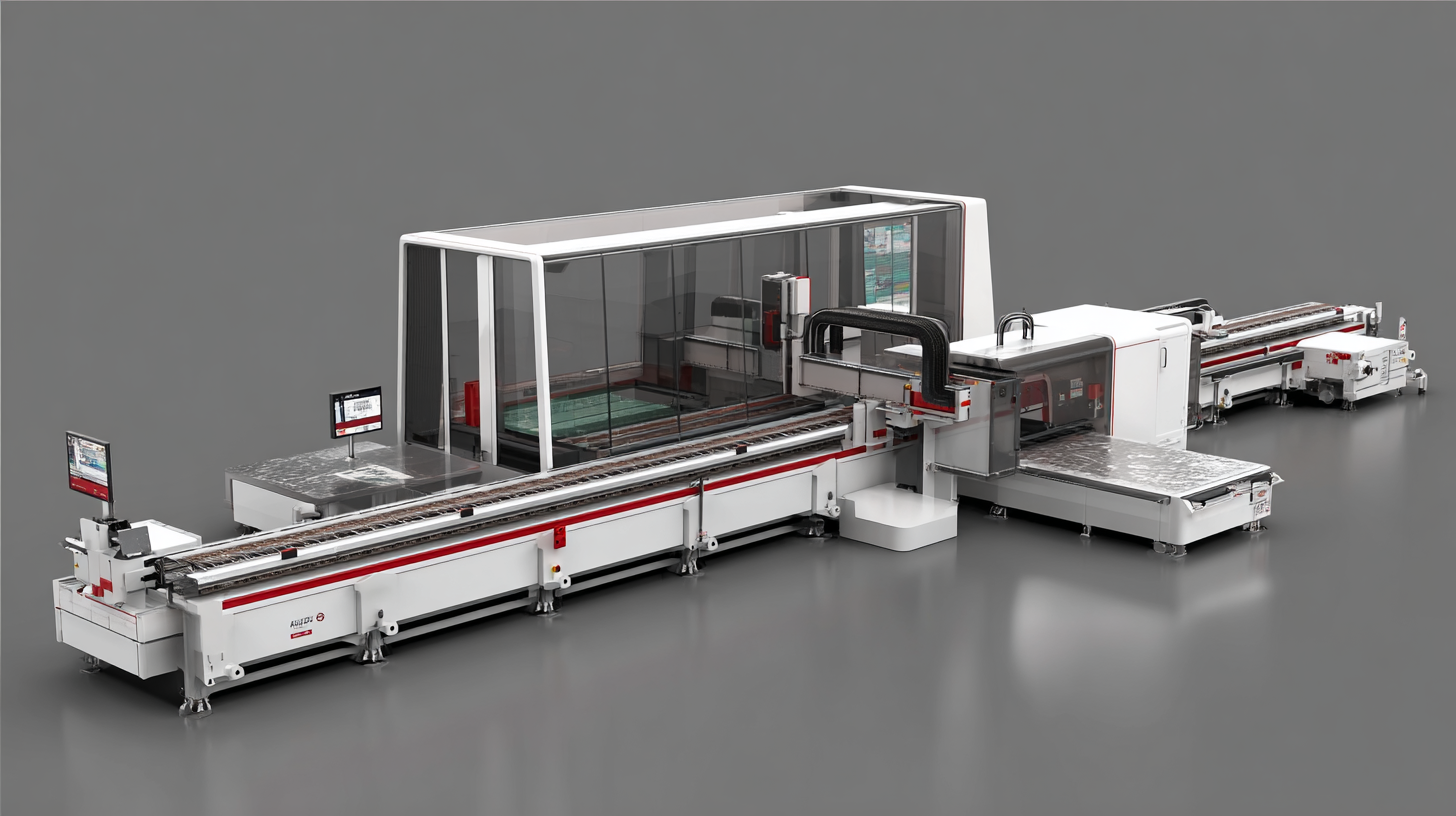

CNC glass cutting machines have seen remarkable advancements, driven by cutting-edge technologies that enhance precision and efficiency. Innovations such as fully automated robotic arms and AI integration are revolutionizing how glass is cut, reducing human error and increasing productivity. These technologies not only enable intricate designs to be executed with impeccable accuracy but also allow for real-time monitoring and adjustments, ensuring optimal results with every cut.

Another significant development in the realm of CNC glass cutting is the integration of advanced software solutions. These systems utilize sophisticated algorithms to streamline the design process and optimize material usage, minimizing waste. By harnessing the power of data analytics, manufacturers can also predict maintenance needs before failures occur, improving uptime and operational efficiency. These transformative innovations position CNC glass cutting machines at the forefront of modern manufacturing, offering solutions that meet the diverse needs of industries ranging from architecture to automotive.

Innovative Solutions for Your CNC Glass Cutting Machine Needs

Customizable CNC Glass Cutting Solutions for Unique Project Requirements

In the world of glass fabrication, each project presents its own unique challenges and requirements, making

customizable CNC glass cutting solutions essential for optimal results. As businesses seek to differentiate themselves,

the ability to tailor CNC machines to specific project needs can lead to enhanced productivity and precision. Customizing your CNC glass cutting machine allows for adaptation to various glass types,

thicknesses, and shapes, ensuring that even the most intricate designs can be executed flawlessly.

Innovative technologies in CNC glass cutting not only improve operational efficiency but also expand the artistic possibilities for designers and engineers.

From adjustable cutting heads that cater to different angles to software that supports complex geometries,

customization empowers users to push boundaries. By investing in bespoke solutions, companies can streamline their workflows,

reduce waste, and ultimately deliver higher quality products that satisfy customer demands.

Whether you are working on custom architectural designs or bespoke glass art, tailored CNC solutions provide the versatility needed to meet

and exceed unique project requirements.

Comparative Analysis of Alternative CNC Cutting Techniques and Their Benefits

The growth of technology in the glass cutting sector has led to innovative solutions that now assist artisans in improving their production efficiency. Traditional CNC glass cutting machines have been complemented by modern techniques like laser cutting, which offers remarkable speed and precision. For instance, laser engraving and cutting machines can execute intricate designs within mere seconds, a feat that was once only possible through tedious manual labor. This accommodation of both art and technology has edged out traditional methods in industries where precision and efficiency are paramount.

Furthermore, the comparative analysis of CNC cutting techniques reveals a myriad of benefits. While conventional CNC machines can be effective, they often require extensive setup and craftsmanship. In contrast, laser cutting technology simplifies the process dramatically, making it accessible even for complex geometric patterns. The efficiency, coupled with the ability to achieve designs that reflect traditional artistry—such as Chinese papercutting—highlights how modern methods can revitalize ancient art forms. The integration of these advanced cutting solutions is not just about improving production speed; it's about preserving and showcasing cultural heritage through innovative means.

Eco-Friendly Approaches to CNC Glass Cutting: Sustainable Alternatives to Consider

In recent years, the glass manufacturing industry has witnessed a significant shift towards eco-friendly practices, particularly in CNC glass cutting. As consumers increasingly demand sustainable solutions, manufacturers are exploring alternative approaches that not only enhance efficiency but also minimize environmental impact. A report by the International Glass Association indicates that the adoption of green technologies in glass processing can reduce energy consumption by up to 30%, making it an essential consideration for modern manufacturing.

One innovative solution gaining traction is the use of advanced waterjet technology for CNC glass cutting. This method utilizes high-pressure water mixed with abrasives, resulting in minimal waste and reducing the need for harmful cutting fluids. Furthermore, a study published in the Journal of Cleaner Production highlights that waterjet cutting can be implemented with up to 97% material utilization, meaning that more glass is used effectively, reducing the need for raw material extraction. Manufacturers implementing these eco-friendly technologies not only benefit from cost savings but also enhance their corporate social responsibility profiles in a market that increasingly prioritizes sustainability.

Additionally, the integration of renewable energy sources, such as solar power, into CNC operations has shown promising results. A recent analysis concluded that incorporating solar energy could lower operational costs by 20% and decrease greenhouse gas emissions significantly. By embracing these sustainable alternatives, manufacturers are paving the way for a greener future in the glass industry, demonstrating that eco-consciousness and profitability can go hand in hand.

Home

About Us

Products

UPVC PVC Window Machine

Aluminum Window Machine

Glass Cutting Machine

Glass Edging Machine

Insulating Glass Machine

Glass lifting machine

Glass Washing Machine

Glass Laminating Machine

Glass Sandblasting Machine

Glass Drilling Machine

CNC Glass Working Center

CNC Non-Metal Cutting Machine

The Other Glass Machinery

Application

Download

News

Contact Us