Exploring Innovations in Glass Loading Machines at China's 138th Canton Fair 2025: Industry Insights and Trends

The 138th Canton Fair in 2025 is poised to showcase groundbreaking advancements in various industries, particularly in the realm of

Glass Loading Machines. As the glass manufacturing sector continues to evolve, the demand for innovative and efficient loading solutions has surged, driven by the industry's projected

growth rate of over 5% annually through 2027. Recent reports indicate that the global market for glass loading systems is expected to reach approximately

$1.2 billion, highlighting the increasing emphasis on automation and precision in manufacturing processes.

At this premier trade fair, industry leaders and innovators will unveil state-of-the-art Glass Loading Machines designed to enhance productivity and reduce operational costs.

With a focus on sustainability and energy efficiency, these innovations are not only set to transform production lines but also align with global trends aiming for

a greener industrial ecosystem. The exploration of these advancements at the Canton Fair will provide invaluable insights into future market trajectories and industry standards.

Innovative Technologies Showcased in Glass Loading Machines at Canton Fair 2025

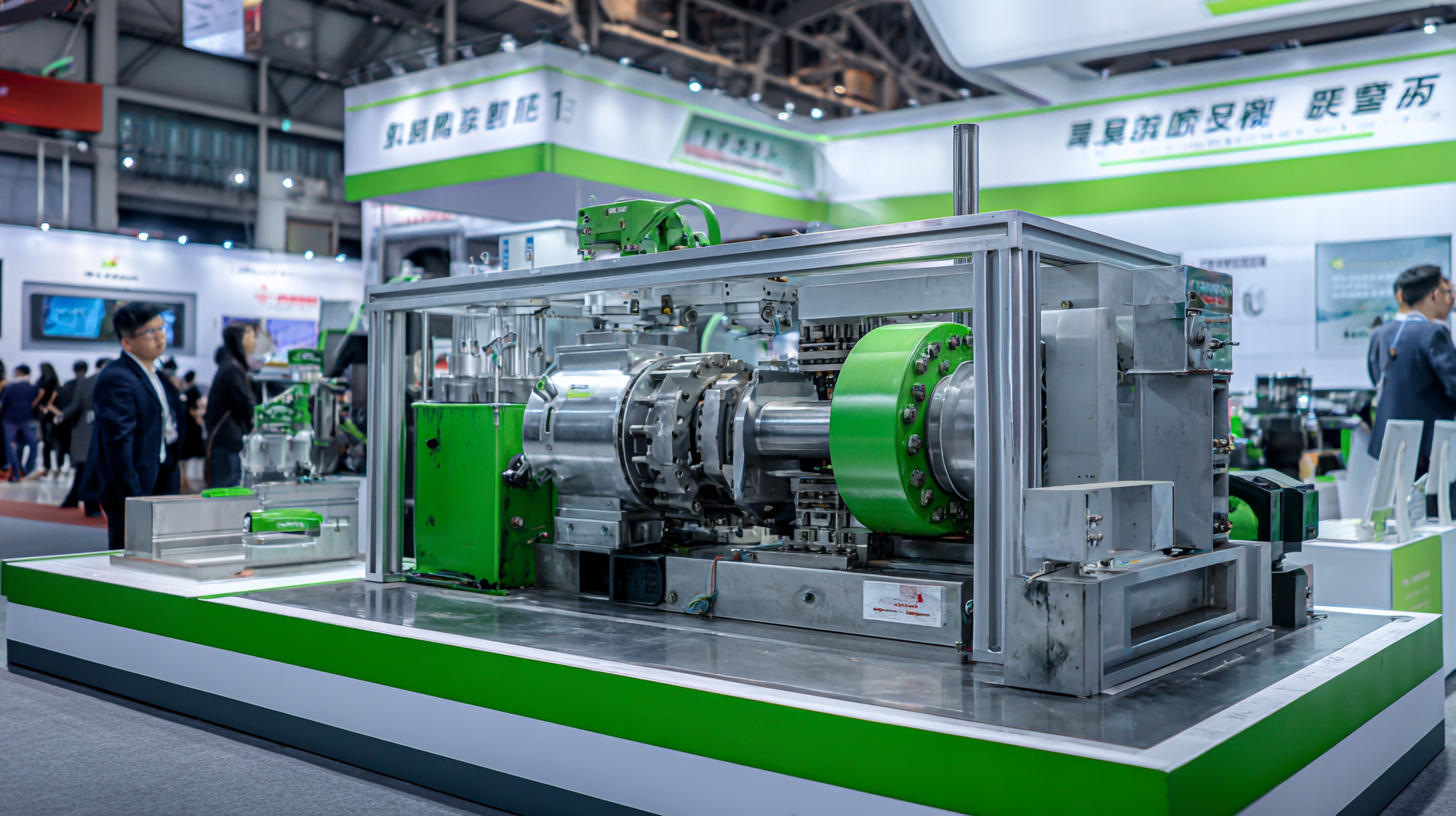

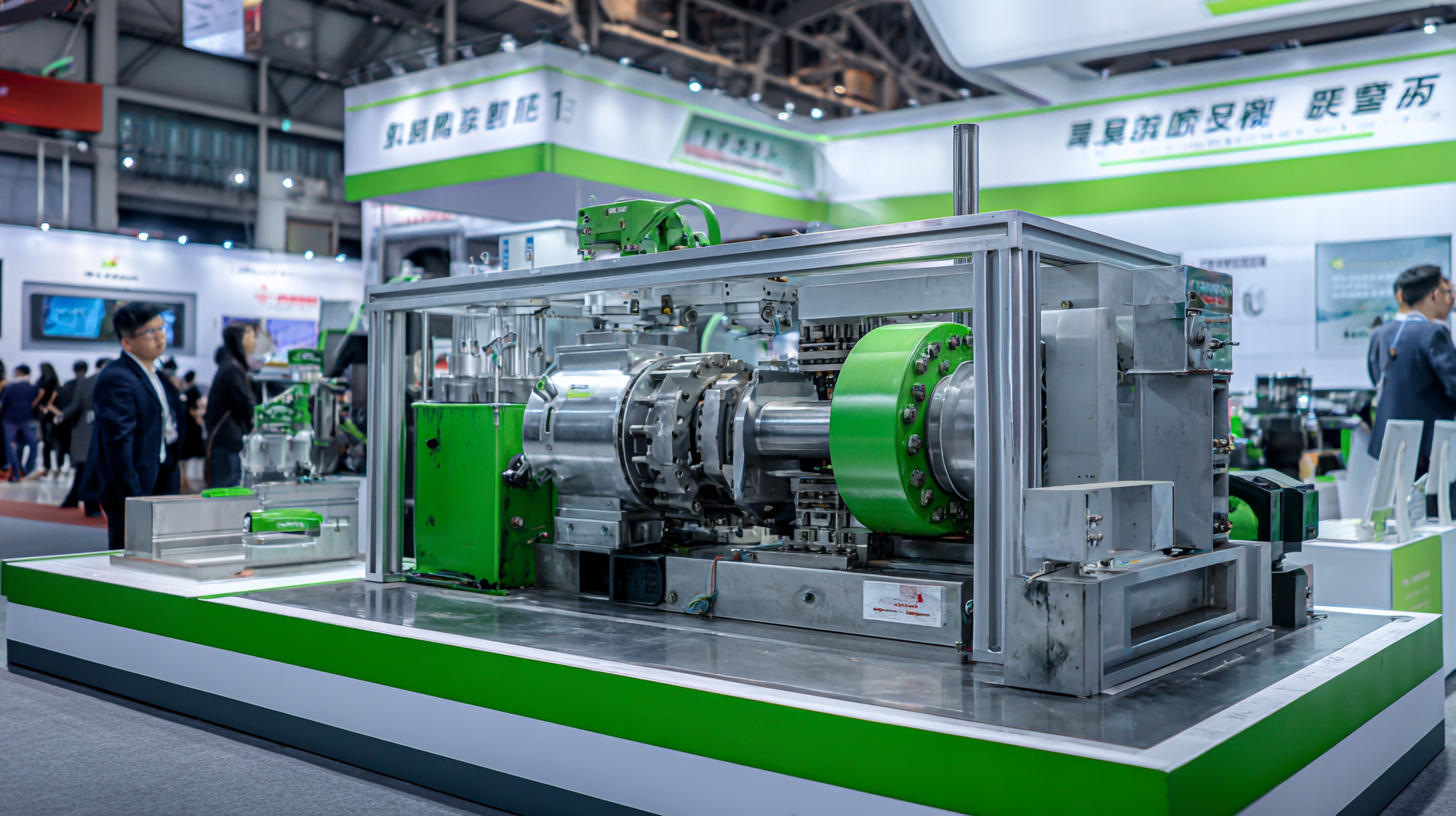

At the 138th Canton Fair in 2025, the spotlight was on groundbreaking advancements in glass loading machines, showcasing innovative technologies that promise to revolutionize the industry. Vendors displayed machines that integrate artificial intelligence and robotic automation, enhancing precision and efficiency in glass handling. These technologies not only streamline the loading process but also minimize human error, providing manufacturers with improved productivity and reducing waste during production cycles.

Another key trend observed at the fair was the incorporation of smart sensors and IoT connectivity in glass loading systems. These features allow for real-time monitoring and data analysis, enabling operators to optimize workflows and predict maintenance needs before issues arise. The interaction between machines and cloud-based platforms paves the way for smarter factories, where decision-making is enhanced through data-driven insights. This convergence of technology reflects a significant shift towards automation and efficiency in the glass manufacturing sector, making it an exciting time for industry stakeholders.

Impact of Automation on Glass Loading Efficiency at the 138th Canton Fair

At the 138th Canton Fair in 2025, the focus on automation in glass loading machines is set to transform industry practices. With high competition and rising demand for efficiency, manufacturers are increasingly investing in advanced technologies that enhance loading processes. Automation not only streamlines operations but also minimizes human error, significantly boosting overall productivity. This trend is evident in the innovative designs showcased at the fair, which emphasize smart integration and real-time monitoring capabilities.

The impact of automation on glass loading efficiency is profound, leading to faster turnaround times and reduced labor costs. Exhibitors are demonstrating how automated systems can adapt to varying glass shapes and sizes, offering flexibility that manual processes cannot match. Furthermore, the incorporation of AI and machine learning allows for predictive maintenance, ensuring that machinery operates at peak performance and reducing downtime. As the industry embraces these innovations, stakeholders are witnessing not just enhanced operational efficiency, but also a redefinition of standards in quality control and safety measures in glass handling.

Emerging Trends in Sustainability for Glass Loading Equipment

At the 138th Canton Fair in 2025, the spotlight is set on the emerging trends in sustainability for glass loading equipment. As industries worldwide strive to reduce their environmental footprint, manufacturers are increasingly integrating eco-friendly practices into the production and operation of glass loading machines. Innovative materials with lower carbon emissions and energy-efficient designs are becoming the new standards, enabling businesses to enhance their sustainability goals while maintaining operational efficiency.

Additionally, advancements in automation and smart technologies are reshaping the glass loading equipment landscape. IoT-enabled machines not only optimize resource utilization but also provide real-time data analytics, allowing manufacturers to monitor their energy consumption and waste management processes more effectively. This trend aligns with the growing demand for transparency and accountability in sustainability efforts, as companies seek to demonstrate their commitment to environmental responsibility. By adopting these innovations, the glass loading industry is poised to lead the way toward a more sustainable future, responding to both market demands and regulatory requirements.

Innovations in Glass Loading Machines: Trends in Sustainability

Comparative Analysis of Global and Chinese Glass Loading Innovations

At the 138th Canton Fair in 2025, glass loading machines are taking center stage, showcasing a vast arena of innovations that reflect both global trends and local advancements, particularly in China. According to the latest industry reports from the International Glass Association, the global glass manufacturing industry is projected to grow at a CAGR of 3.5% from 2023 to 2028. This growth drives demand for more efficient and innovative loading machines that can enhance production lines while reducing costs.

Chinese manufacturers are leading this charge with significant advancements in automation and artificial intelligence. A comparative analysis reveals that while global competitors focus on energy efficiency, Chinese innovations are pushing boundaries with smart technologies like IoT-enabled systems that provide real-time monitoring and predictive maintenance. For example, a market survey by Mordor Intelligence indicates that the adoption of AI-driven solutions in glass loading processes could reduce operational costs by up to 20%. As global standards rise, the integration of these innovative solutions positions Chinese manufacturers at the forefront of the glass loading machinery market, providing them a competitive edge in both domestic and international markets.

Future Prospects for the Glass Industry Post-Canton Fair 2025

The glass industry is on the cusp of significant transformation, especially in the aftermath of the 138th Canton Fair 2025. As global demand for innovative glass products increases, the integration of technology in glass loading machines has become a focal point for manufacturers aiming to boost efficiency and productivity. This innovation not only streamlines production processes but also enhances output quality, positioning the sector for robust growth in the coming years.

Looking ahead, the glass industry is set to benefit from the anticipated expansion of related markets. With a projected market size growth from $44.39 billion in 2025 to $70.28 billion by 2032, the industry is well-poised to harness emerging trends. The integration of smart technologies and automation is driving this momentum, aligning with global shifts toward sustainable and efficient manufacturing practices. Stakeholders are keenly observing these developments, indicating a promising horizon for the glass sector post-Canton Fair 2025.

Exploring Innovations in Glass Loading Machines at China's 138th Canton Fair 2025: Industry Insights and Trends

| Category |

Innovation Type |

Application Area |

Market Impact |

Future Prospects |

| Automation |

Robotic Loading Systems |

Manufacturing Lines |

Increased Efficiency |

High Demand for Smart Automation |

| Sustainability |

Eco-friendly Materials |

Packaging |

Reduced Environmental Impact |

Growing Consumer Preference for Green Products |

| Technology |

Smart Sensors |

Quality Control |

Enhanced Accuracy |

Integration with IoT |

| Safety |

Advanced Safety Features |

Loading Operations |

Reduced Accidents |

Increased Regulatory Compliance |

| Customization |

Modular Systems |

Various Industries |

Versatile Applications |

Adaptability to Market Needs |

Home

About Us

Products

UPVC PVC Window Machine

Aluminum Window Machine

Glass Cutting Machine

Glass Edging Machine

Insulating Glass Machine

Glass lifting machine

Glass Washing Machine

Glass Laminating Machine

Glass Sandblasting Machine

Glass Drilling Machine

CNC Glass Working Center

CNC Non-Metal Cutting Machine

The Other Glass Machinery

Application

Download

News

Contact Us