What is the Importance of Manual Glass Cutting Tables in Modern Manufacturing

In the rapidly evolving landscape of modern manufacturing, the significance of precision and efficiency cannot be overstated, particularly in the glass industry.

Manual Glass Cutting Tables have emerged as essential tools in this realm, significantly impacting production quality and operational efficiency.

According to a recent report by Research and Markets, the global glass processing market is projected to grow by 7.2% annually, highlighting the increasing demand for high-quality glass products.

The adoption of Manual Glass Cutting Tables allows manufacturers to achieve intricate designs and precise cuts, which are crucial for meeting the stringent standards of both residential and commercial applications.

Furthermore, a study by the International Journal of Advanced Manufacturing Technology suggests that utilizing such manual cutting solutions can enhance productivity while reducing waste, ultimately contributing to lower production costs.

As the industry pivots towards more sustainable practices, the importance of Manual Glass Cutting Tables becomes increasingly prominent as they blend craftsmanship with modern technology.

Manual Glass Cutting Tables have emerged as essential tools in this realm, significantly impacting production quality and operational efficiency.

According to a recent report by Research and Markets, the global glass processing market is projected to grow by 7.2% annually, highlighting the increasing demand for high-quality glass products.

The adoption of Manual Glass Cutting Tables allows manufacturers to achieve intricate designs and precise cuts, which are crucial for meeting the stringent standards of both residential and commercial applications.

Furthermore, a study by the International Journal of Advanced Manufacturing Technology suggests that utilizing such manual cutting solutions can enhance productivity while reducing waste, ultimately contributing to lower production costs.

As the industry pivots towards more sustainable practices, the importance of Manual Glass Cutting Tables becomes increasingly prominent as they blend craftsmanship with modern technology.

The Evolution of Manual Glass Cutting Tables in Manufacturing

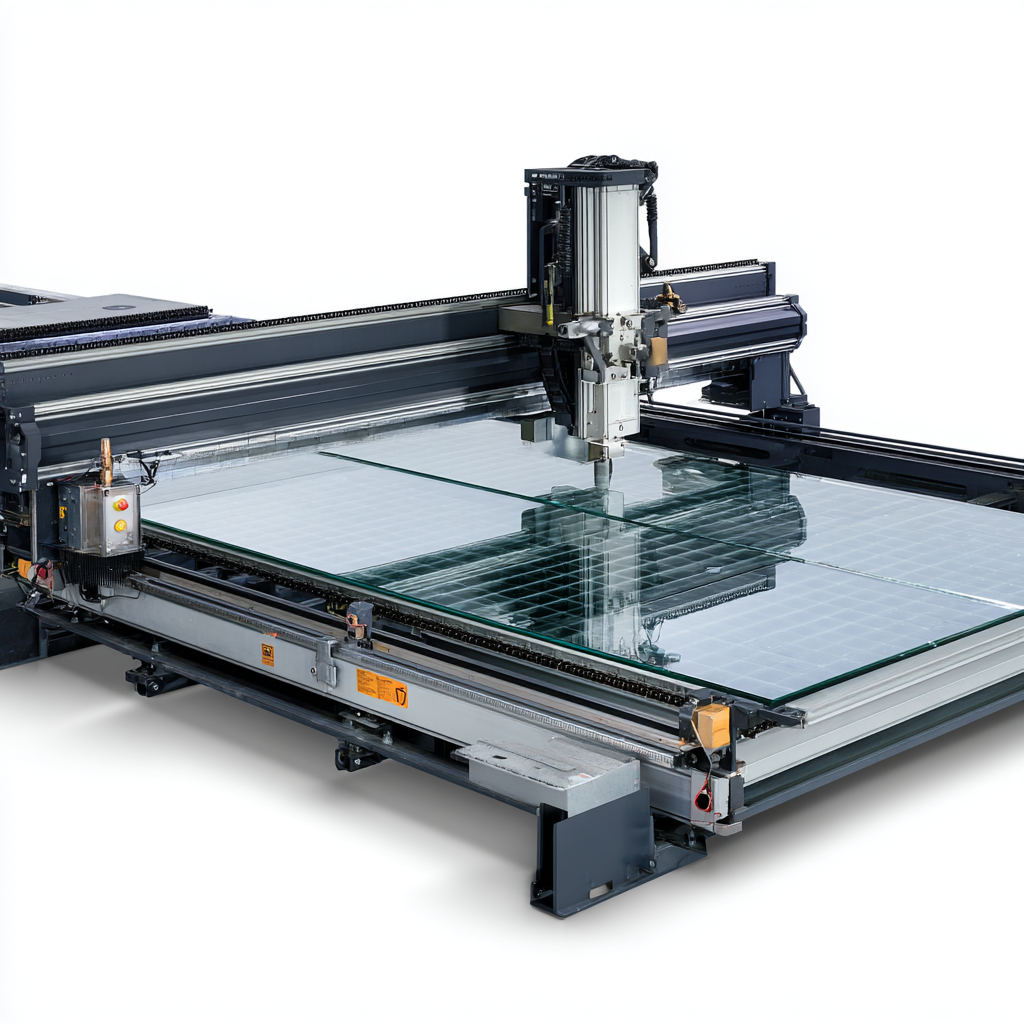

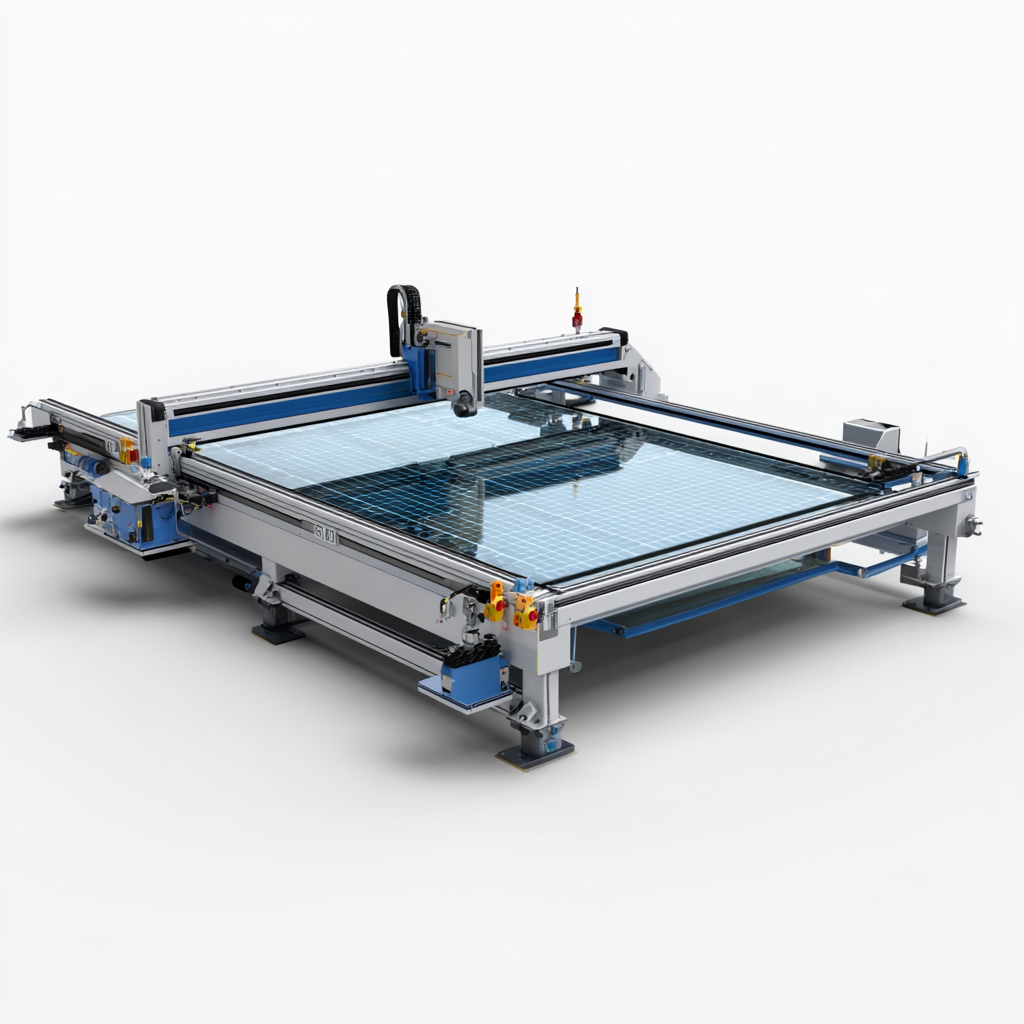

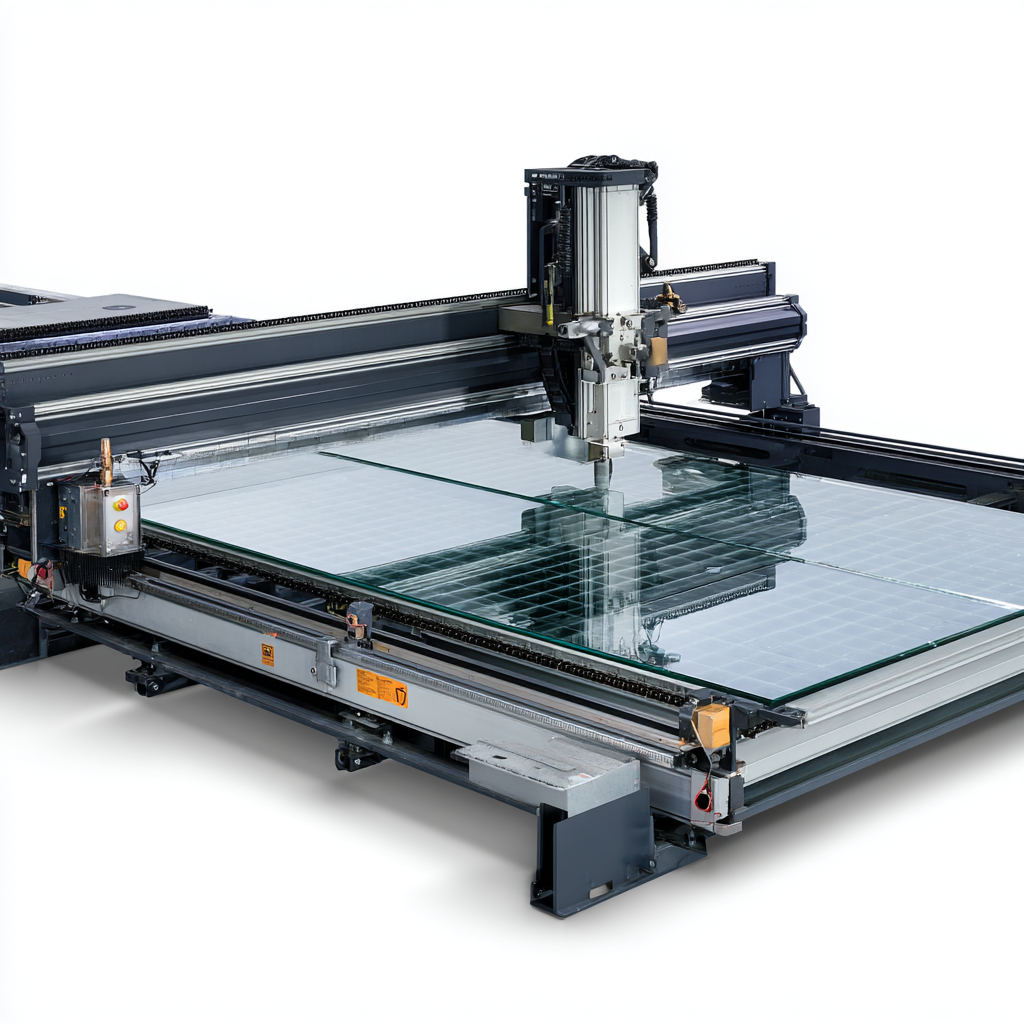

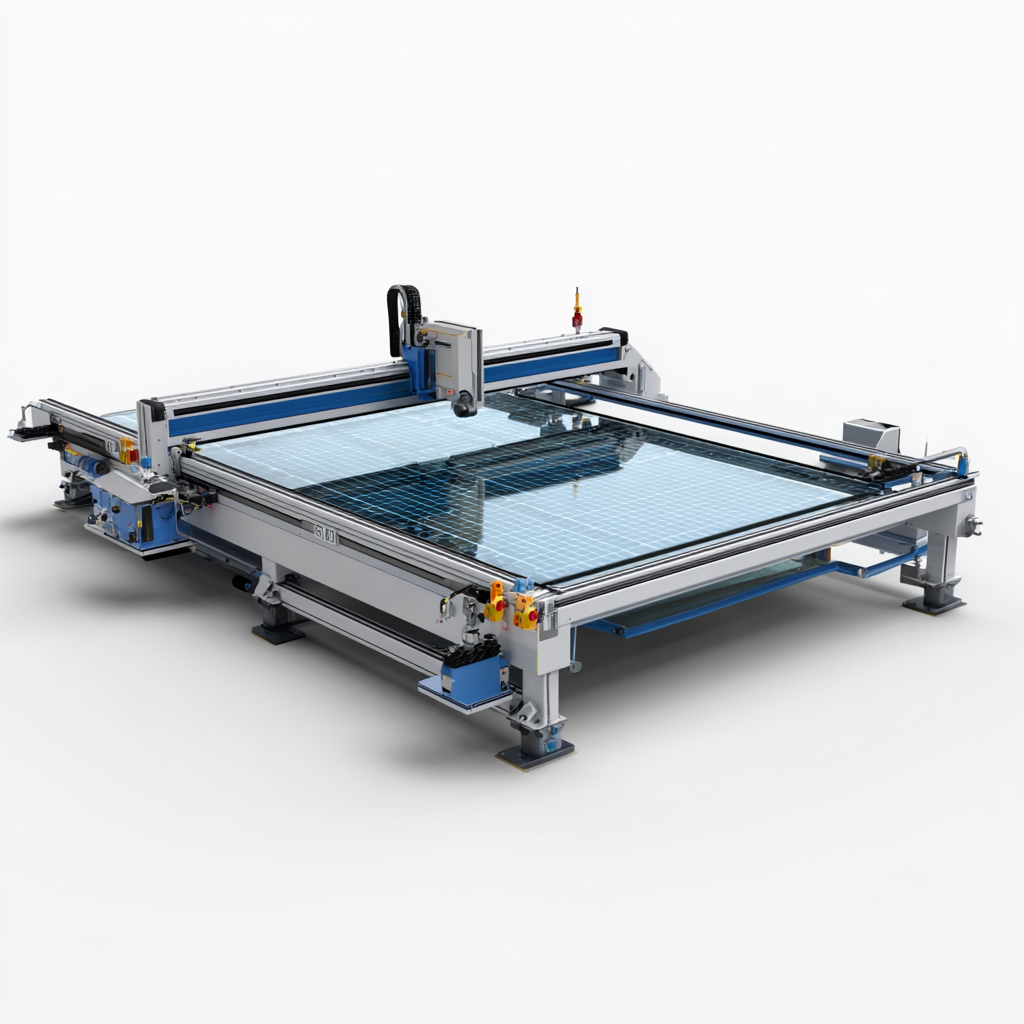

The evolution of manual glass cutting tables in manufacturing has been marked by significant advancements that reflect both technological innovations and the demands of modern production. In the early days, craftsmen relied on rudimentary tools and techniques, often cutting glass by hand using simple guides and measuring tools. This process was labor-intensive and required immense skill to ensure precision and minimize waste. However, as industries grew and the need for efficiency increased, manufacturers began to develop specialized cutting tables that enhanced both speed and accuracy.

With the introduction of more advanced designs, manual glass cutting tables have incorporated features such as adjustable cutting heads, integrated measuring systems, and specialized surfaces that improve the stability of the glass during the cutting process. This evolution has allowed for greater flexibility, enabling manufacturers to create custom shapes and sizes with precision. Furthermore, ergonomic designs have improved operator comfort and safety, making it possible for workers to produce high-quality cuts without the risk of injury.

Today's manual glass cutting tables not only showcase refined craftsmanship but also highlight the continuous adaptation of manufacturing practices to meet the complexities of modern demands.

Key Features of Modern Manual Glass Cutting Tables

Modern manual glass cutting tables are essential tools in the glass manufacturing industry, providing accuracy and efficiency in cutting processes. One of the standout features of these tables is their precision cutting technology, often incorporating advanced scoring systems that ensure clean, accurate cuts every time. According to a report by Smithers Pira, the global glass processing market is expected to reach over $35 billion by 2025, highlighting the increasing demand for high-quality glass products. This growing market emphasizes the importance of specialized equipment like manual glass cutting tables in facilitating superior workmanship.

Another key feature of modern manual glass cutting tables is their adaptability to various glass types and thicknesses. Many tables offer adjustable cutting parameters, allowing operators to handle a range of materials—from standard float glass to specialized laminated glass. This versatility is crucial for manufacturers who need to keep up with diverse client demands and trends. Furthermore, ergonomic designs are becoming standard in these tables, reducing the physical strain on operators and increasing efficiency on the production floor.

**Tips:** When selecting a manual glass cutting table, consider models with integrated safety features to enhance workplace safety. Regular maintenance of the cutting equipment can also prolong its lifespan and maintain cutting precision, ensuring consistent output quality.

Importance of Manual Glass Cutting Tables in Modern Manufacturing

The Benefits of Manual Glass Cutting in Precision Engineering

Manual glass cutting tables play a crucial role in precision engineering, offering a unique blend of control and customization that modern manufacturing demands. With these tables, artisans can manipulate the glass with meticulous attention to detail, ensuring that every cut is executed flawlessly. This level of precision is vital in industries where the slightest deviation can compromise quality or functionality, such as in aerospace, automotive, and architectural applications.

Furthermore, manual glass cutting allows for greater flexibility in design. Unlike automated processes, which may be limited to specific patterns and shapes, manual cutting enables craftsmen to tailor each piece to meet unique specifications. This adaptability is particularly important when working with custom orders or intricate designs that require a human touch. The skill of the operator combined with the use of a manual glass cutting table ensures that manufacturers can achieve high-quality results while accommodating the diverse needs of their clients.

Comparing Manual and Automated Glass Cutting Methods

In modern manufacturing, the choice between manual and automated glass cutting methods plays a crucial role in efficiency and precision. Manual glass cutting tables offer unique advantages that can be particularly beneficial for smaller operations or specialized tasks. The hands-on control allows skilled operators to make quick adjustments on the fly, ensuring that each cut meets the specific needs of the project. This adaptability can be essential for intricate designs where precision is paramount.

Tips for using manual glass cutting tables effectively include ensuring that the cutting tools are regularly maintained for optimal performance. Additionally, it is essential to have a well-organized workstation, as a clutter-free environment enhances focus and minimizes the risk of mistakes. Operators should also consider practicing different cutting techniques to improve their skills and familiarity with various glass types.

On the other hand, automated glass cutting equipment brings a different set of benefits, such as speed and uniformity in production. While these machines can handle high volumes with impressive accuracy, they may lack the flexibility that manual methods provide. Businesses must weigh the pros and cons of each approach based on their specific requirements, production scale, and budget constraints to find the most suitable solution for their glass cutting needs.

What is the Importance of Manual Glass Cutting Tables in Modern Manufacturing - Comparing Manual and Automated Glass Cutting Methods

| Criteria |

Manual Glass Cutting |

Automated Glass Cutting |

| Cost |

Lower initial investment |

Higher upfront cost |

| Setup Time |

Longer setup time |

Quick setup |

| Flexibility |

Highly flexible for various designs |

Less flexible; optimized for standard cuts |

| Labor Skill Requirement |

Requires skilled labor |

Operators need basic training |

| Production Speed |

Slower production speed |

Faster production speed |

| Waste Material |

May have higher waste |

Reduced waste via precision cuts |

| Maintenance |

Low maintenance required |

Requires regular maintenance |

The Role of Manual Glass Cutting Tables in Sustainable Manufacturing Practices

In today's quest for sustainable manufacturing practices, manual glass cutting tables play a pivotal role. These tables are not only essential for precision in glass cutting, but they also contribute significantly to waste reduction. By allowing skilled operators to cut glass with great accuracy, these tables minimize the amount of scrap generated during the cutting process, leading to a more efficient use of materials. This efficiency aligns with the core principles of sustainable manufacturing, where reducing material waste is crucial for environmental conservation.

Tips for optimizing the use of manual glass cutting tables include regular maintenance to ensure precision and durability. Keeping the cutting surface smooth and free from debris greatly enhances the quality of each cut, reducing mistakes that could lead to waste. Moreover, training operators on best practices can further enhance efficiency. By focusing on proper techniques and methods, manufacturers can achieve smoother cuts and ultimately lower their material costs.

Additionally, integrating manual glass cutting tables into a circular economy mindset can position manufacturers as leaders in sustainability. This can involve repurposing leftover glass scraps for new products or ensuring that all waste is recycled appropriately. By fostering an innovative approach towards material usage, businesses can not only improve their sustainability metrics but also enhance their reputation in an increasingly eco-conscious market.

Home

About Us

Products

UPVC PVC Window Machine

Aluminum Window Machine

Glass Cutting Machine

Glass Edging Machine

Insulating Glass Machine

Glass lifting machine

Glass Washing Machine

Glass Laminating Machine

Glass Sandblasting Machine

Glass Drilling Machine

CNC Glass Working Center

CNC Non-Metal Cutting Machine

The Other Glass Machinery

Application

Download

News

Contact Us