What is a Glass Shape Beveling Machine? Exploring Its Applications and Industry Insights

The Glass Shape Beveling Machine is an essential tool in the glass processing industry, transforming raw glass sheets into finely beveled edges for a variety of applications. According to a recent market analysis from Research and Markets, the global glass processing machinery market is projected to grow at a CAGR of 5.1% from 2021 to 2026, indicating a robust demand for specialized machines like the beveling machine. These machines enhance the aesthetic appeal and safety of glass products, making them vital in sectors ranging from architecture to automotive. With advancements in technology, modern Glass Shape Beveling Machines are equipped with precise control systems that improve efficiency and quality, addressing the industry's need for high-performance solutions. This blog will delve deeper into the functionalities of these machines, their applications across different industries, and the insights that underscore their significance in contemporary glass production.

Understanding the Basics of Glass Shape Beveling Machines

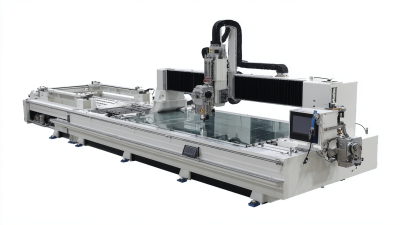

Glass shape beveling machines are essential tools in the glass processing industry, designed to create precise angles and edges on glass products. By employing advanced technologies, these machines enhance both the aesthetic appeal and functional characteristics of glass items. According to a recent industry report by Market Research Future, the global glass processing market is projected to reach USD 39 billion by 2025, indicating a strong demand for specialized machinery like beveling machines.

These machines operate by using diamond grinding wheels to shape the glass edges, allowing for intricate designs that meet both commercial and residential needs. The versatility of glass shape beveling machines makes them invaluable in various sectors, including architecture and automotive industries. As noted in a report by Mordor Intelligence, the demand for decorative glass in interior architecture is expected to grow significantly, further driving the need for advanced beveling technologies. With the rise of custom glass applications, manufacturers are focusing on integrating automation and precision into beveling processes, thus streamlining production and minimizing waste.

Key Features and Technologies of Beveling Machines

Beveling machines are essential tools in the fabrication and manufacturing industries, designed to create precise angled edges on metal sheets and components. The key features of modern beveling machines include advanced cutting technologies that enhance efficiency and accuracy.

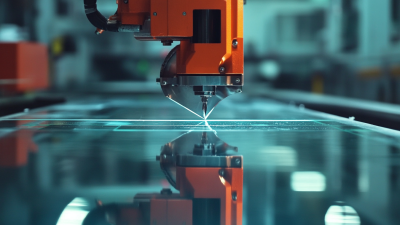

Notably, laser bevel cutting technology has emerged as a revolutionary approach, allowing for high-precision bevels at various angles, often up to 50 degrees. This technology not only improves the quality of the finished products but also significantly reduces waste material, making it a preferred choice among manufacturers aiming for sustainability.

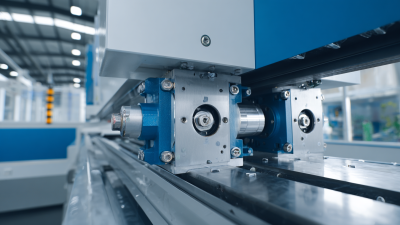

In addition to laser cutting, beveling machines often incorporate automation technologies, which streamline the production process. Intelligent systems enable multipass welding capabilities in configurations like Butt Double V-Groove and Tee Double Bevel, optimizing weld quality and speed.

These innovations reflect the industry's commitment to enhancing productivity while meeting the increasing demand for custom metal fabrication solutions. As the market for such equipment continues to expand, staying informed about the latest technologies and their applications is crucial for businesses looking to maintain a competitive edge.

Applications of Glass Shape Beveling in Various Industries

Glass shape beveling machines play a crucial role in various industries, refining and enhancing the aesthetic appeal of glass products. In the architecture and construction sector, beveling is frequently used for glass panels, providing a sleek and polished finish that complements modern designs. This not only improves the visual appeal but also aids in safety by eliminating sharp edges. Similarly, in the furniture industry, beveling adds elegance to glass tabletops and displays, creating stunning visual statements.

In the automotive and aerospace industries, beveled glass is essential for components like windshields and cockpit panels. The beveling process helps to ensure a secure fit and contributes to the overall strength of the glass, ensuring safety and performance in high-stress environments. Additionally, the manufacturing of art glass and custom glass products also benefits significantly from beveling techniques, allowing artisans to create unique, one-of-a-kind pieces.

Tip: When choosing a glass shape beveling machine, consider factors such as precision, speed, and ease of operation to ensure a seamless integration into your production process.

Tip: Regular maintenance of the beveling machine will enhance its longevity and performance, reducing downtime and ensuring consistent quality in your glass products.

Comparative Analysis of Beveling Methods in Glass Processing

Beveling is a crucial process in glass manufacturing, enhancing both the aesthetic appeal and functionality of glass products. Various methods are employed in glass beveling, each with its own advantages and applications. Traditional hand beveling, while labor-intensive, allows for intricate designs and personal touch, making it ideal for bespoke projects. However, this method can be time-consuming and requires skilled artisans, which may not be suitable for high-volume production needs.

On the other hand, modern machines, such as glass shape beveling machines, utilize advanced technology for precision and efficiency. These machines automatically bevel glass edges, ensuring uniformity and reducing waste. Some advanced models even incorporate CNC (Computer Numerical Control) for complex shapes, allowing manufacturers to meet diverse client requirements quickly. A comparative analysis of these methods reveals that machine-assisted beveling is increasingly favored in industrial settings, where speed and consistency are paramount, while hand beveling remains popular for specialty items. The choice between these methods often depends on production volume, the nature of the project, and budget constraints.

Future Trends in Glass Beveling Technology and Market Insights

The glass beveling industry is witnessing significant advancements driven by technology and evolving market demands. One of the notable future trends in glass beveling technology is the integration of automation and artificial intelligence. These innovations enable precise control over the beveling process, resulting in enhanced productivity and reduced waste. As manufacturers seek to improve efficiency and accuracy, the adoption of smart machines equipped with sensor technology and data analytics is becoming more common, allowing for real-time monitoring and adjustments.

Another crucial trend is the growing emphasis on environmentally friendly practices within the glass processing sector. Companies are increasingly focusing on sustainable sourcing of materials and implementing eco-friendly solutions in their manufacturing processes. This shift aligns with global efforts to reduce carbon footprints and promote greener alternatives. As demand for eco-conscious products rises, glass beveling machines that incorporate energy-efficient technologies, such as programmable features that optimize power usage, are expected to gain traction in the marketplace, meeting both consumer expectations and regulatory standards.

Glass Beveling Machine Market Overview

This bar chart illustrates the market share distribution of glass beveling machines across different regions. As seen, Asia holds the largest share, indicating a robust demand for glass beveling technology in that region. North America and Europe also represent significant portions of the market, reflecting their advanced glass processing industries.

Home

About Us

Products

UPVC PVC Window Machine

Aluminum Window Machine

Glass Cutting Machine

Glass Edging Machine

Insulating Glass Machine

Glass lifting machine

Glass Washing Machine

Glass Laminating Machine

Glass Sandblasting Machine

Glass Drilling Machine

CNC Glass Working Center

CNC Non-Metal Cutting Machine

The Other Glass Machinery

Application

Download

News

Contact Us