What is a Glass Grinding Machine and How Does It Work?

A Glass Grinding Machine is a vital tool in the glass manufacturing industry. This machine shapes and smooths glass edges with precision. According to industry expert Dr. Samuel Greene, "The efficiency of a Glass Grinding Machine can significantly enhance production quality."

Glass grinding involves removing sharp edges and creating desired shapes. The process helps in safety and aesthetics. Many businesses rely on this technology to ensure product longevity. However, not all machines are created equal. Some may struggle with consistency, leading to imperfections. It's crucial to choose the right machine for specific needs.

Innovations in Glass Grinding Machines continue to emerge. New technologies aim to enhance speed and accuracy. Despite advancements, there are still challenges to address. Each machine has its limitations, which require careful consideration. Understanding these nuances is key to success in glass processing.

What is a Glass Grinding Machine?

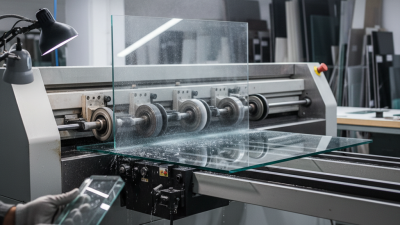

A glass grinding machine is a specialized tool used in the glass industry. Its primary function is to refine the edges of glass pieces, ensuring precision and safety. These machines are essential in various applications, including fabrication, automotive, and construction. In 2022, the global glass processing market was valued at over $30 billion, highlighting the vital role of such machinery.

The operation of a glass grinding machine involves several steps. Typically, it uses abrasive wheels to smooth and shape glass edges. These wheels may vary in grit depending on the desired finish. Some machines also feature automated systems to increase efficiency and reduce human error. However, operators must be careful with machine settings. Incorrect adjustments can lead to uneven edges or glass breakage, resulting in material waste.

Despite advancements in technology, not every glass grinding machine is perfect. Issues like overheating or wear and tear on grinding wheels can arise. Regular maintenance is crucial yet often overlooked. It can significantly prolong the machine's lifespan and improve output quality. The ongoing challenge lies in balancing high productivity with consistent quality. This industry must continuously seek improvements and innovations to address these concerns effectively.

Components of a Glass Grinding Machine

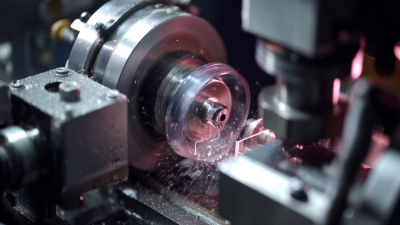

A glass grinding machine is a complex piece of equipment designed to shape and finish glass products. Understanding its components is crucial for anyone involved in glass processing. The main elements include a grinding wheel, a motor, a frame, and a coolant system. Each plays a specific role in the grinding process.

The grinding wheel is the heart of the machine. It is made of abrasive material and determines the smoothness of the glass surface. An operator must select the right wheel for the job; otherwise, the glass may become scratched or uneven. The motor powers the grinding wheel and should be robust to handle various tasks. Sometimes, it can struggle under heavy workloads, which might require frequent maintenance.

The frame holds everything together. It must be sturdy yet accessible for adjustments. A weak frame can lead to vibrations that affect the grinding quality. The coolant system helps in reducing heat during grinding, often overlooked. It can clog or malfunction, leading to subpar results. Operators need to remain vigilant about these aspects while using the machine. Each detail matters in achieving the desired finish.

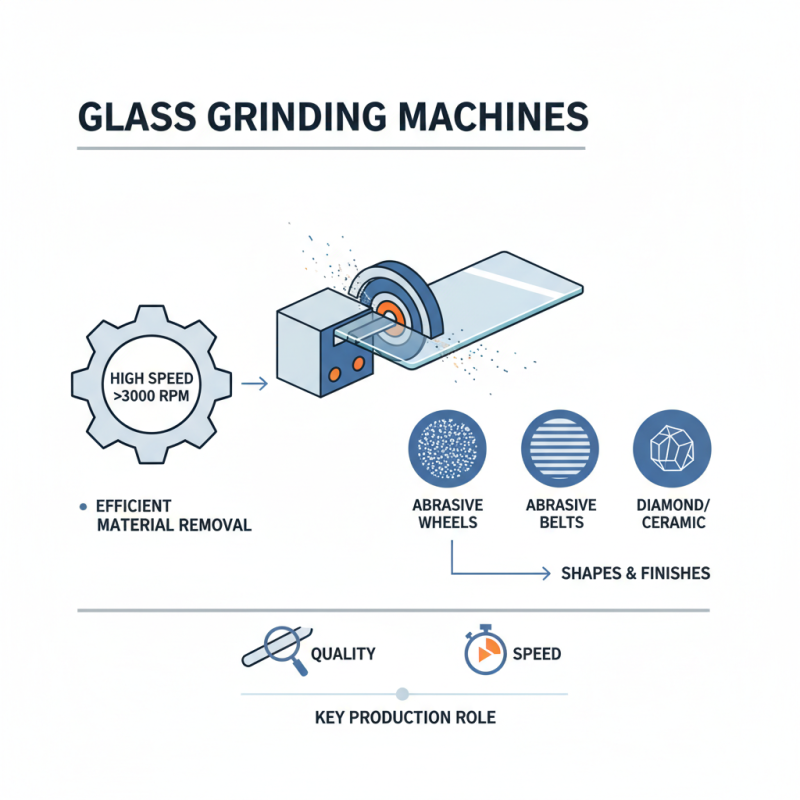

Working Principle of Glass Grinding Machines

Glass grinding machines play a crucial role in the production of glass products. They utilize abrasive wheels or belts to grind glass surfaces to achieve desired shapes and finishes. The abrasive materials can vary, impacting the speed and quality of the grinding process. Typically, these machines operate at high speeds, often exceeding 3,000 RPM. This velocity is essential for effective material removal.

Understanding the working principle is vital. A glass grinding machine uses a rotating wheel that makes contact with the glass surface. The wheel’s grit removes tiny particles from the glass, smoothing the surface. Adjusting the machine settings can change the grinding depth and finish. Data shows that precise control of parameters can increase efficiency by up to 30%. However, many users overlook these settings, leading to inconsistent results.

Moreover, temperature management during grinding is essential. Excessive heat can cause glass to crack or warp, especially with thinner materials. Industry reports indicate that maintaining a cool working environment boosts the machine's lifespan and performance. Operators must regularly monitor these conditions. Ignoring them results in costly mistakes.

Types of Glass Grinding Techniques

Glass grinding is a crucial process in the manufacturing and finishing of glass products. There are various glass grinding techniques, each with unique features. The primary methods include beveling, edge grinding, and flat grinding. According to industry reports, the global glass processing market is expected to grow by 5.4% annually through 2027. This growth is driven by increasing demand in the automotive and construction industries.

Beveling involves creating angled edges on glass pieces. It enhances aesthetics but can be challenging. Precision is crucial to prevent edge chipping. Edge grinding is designed to smooth the rough edges of glass. This technique ensures a safe finish, crucial for user safety. Flat grinding, on the other hand, focuses on creating a flat surface for thicker glass. Machines used for this purpose require high skill levels and regular maintenance.

Despite advancements, some issues remain prevalent. Inconsistent quality can arise from operator skills or machine features. Sometimes, the equipment can show wear and tear over time, affecting performance. Addressing these challenges is essential for maintaining quality control in glass grinding. Data indicates that 30% of defects in glass products stem from grinding errors, highlighting the need for ongoing monitoring and improvement in techniques.

Applications of Glass Grinding Machines in Various Industries

Glass grinding machines are essential tools in various industries. They help create precision edges and surfaces on glass products. Industries such as construction, automotive, and electronics rely heavily on these machines. In fact, the global glass processing market was valued at approximately $24 billion in 2021, showcasing the high demand for glass products and their components.

Construction firms frequently use glass grinding machines. These machines ensure windows, doors, and facades are perfectly finished. A report indicated that 60% of architects prefer glass due to its aesthetic appeal and energy efficiency. Automotive manufacturers also utilize these machines. They need precise glass components for safety and design. According to industry data, the use of glass in vehicles has risen by over 15% during the past five years.

Despite their benefits, challenges exist. Operators must be cautious of the grinding process. Overheating can lead to cracks or poor finishes. Additionally, some machines may require frequent maintenance to ensure peak performance. Balancing efficiency and precision can sometimes be tricky. Operators continually seek ways to enhance productivity while minimizing defects in the finished products.

Applications of Glass Grinding Machines in Various Industries

Home

About Us

Products

UPVC PVC Window Machine

Aluminum Window Machine

Glass Cutting Machine

Glass Edging Machine

Insulating Glass Machine

Glass lifting machine

Glass Washing Machine

Glass Laminating Machine

Glass Sandblasting Machine

Glass Drilling Machine

CNC Glass Working Center

CNC Non-Metal Cutting Machine

The Other Glass Machinery

Application

Download

News

Contact Us