Explore the Future of Glass Edge Polishing Machines at 2025 China Import and Export Fair: Market Trends and Data Insights

As the glass industry continues to evolve, the demand for advanced manufacturing solutions is on the rise. The Glass Edge Polishing Machine plays a crucial role in enhancing product quality and efficiency, making it a pivotal focus at the 138th China Import and Export Fair in 2025. According to recent market research, the global glass processing machinery market is projected to reach $3.5 billion by 2026, with a CAGR of 5.2% during the forecast period. This surge can be attributed to the growing architectural and automotive sectors, which require precision and durability in glass products. At the fair, innovation in glass edge polishing technologies will be showcased, highlighting trends such as automation and energy efficiency, which are becoming increasingly essential for manufacturers aiming to stay competitive. Attendees will gain valuable insights into market dynamics and the future trajectory of glass edge polishing solutions.

The Growing Demand for Advanced Glass Edge Polishing Machines in China

The demand for advanced glass edge polishing machines in China is witnessing significant growth, bolstered by rising market needs and evolving technological capabilities. As manufacturers aim to enhance product quality and efficiency, these sophisticated machines are becoming essential in the glass processing industry. The increasing use of glass in various sectors, such as construction and automotive, further propels this demand, making the upcoming China Import and Export Fair in 2025 a focal point for trends and innovations in this niche market.

The demand for advanced glass edge polishing machines in China is witnessing significant growth, bolstered by rising market needs and evolving technological capabilities. As manufacturers aim to enhance product quality and efficiency, these sophisticated machines are becoming essential in the glass processing industry. The increasing use of glass in various sectors, such as construction and automotive, further propels this demand, making the upcoming China Import and Export Fair in 2025 a focal point for trends and innovations in this niche market.

In conjunction with this, the semiconductor equipment sector in China is also undergoing a transformative phase, marked by an active wave of mergers and acquisitions. These consolidations signal strong confidence in the market's trajectory, aligning with the growing requirements for advanced manufacturing technologies across industries. The interplay between the glass and semiconductor sectors reflects broader economic trends, underscoring the importance of investing in cutting-edge machinery.

Tips:

- Stay informed about advancements in glass edge polishing technologies to better understand market dynamics.

- Engage with industry experts at trade fairs to gain insights into emerging trends and innovations.

- Explore strategic partnerships that could enhance your competitive edge in the evolving manufacturing landscape.

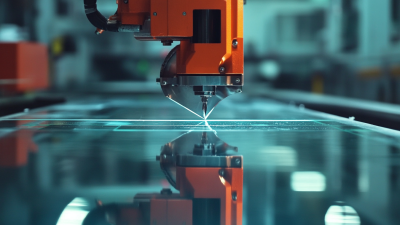

Innovations in Glass Edge Polishing Technology for Enhanced Efficiency

The future of glass edge polishing technology is poised for remarkable advancements, particularly as showcased at the upcoming 2025 China Import and Export Fair. Innovations in this field are primarily focused on enhancing efficiency, quality, and cost-effectiveness in the glass processing industry. With the rise of automation and smart technologies, manufacturers are integrating AI and machine learning into their polishing machines, allowing for precise adjustments and real-time monitoring. This not only reduces manual labor but also minimizes errors, resulting in a higher quality finish and a more streamlined production process.

Moreover, the introduction of eco-friendly materials and energy-efficient designs presents an opportunity for companies to align with global sustainability goals. These technological advancements are expected to significantly lower operational costs while ensuring a minimal environmental footprint. As stakeholders gather at the fair, discussions surrounding the adoption of these innovative solutions will be crucial in shaping market trends and setting new standards for the glass edge polishing industry. Embracing these changes will be vital for businesses looking to maintain a competitive edge in a rapidly evolving marketplace.

Market Trends in Glass Edge Polishing Machines (2025)

This chart illustrates the projected market growth and key technological innovations in glass edge polishing machines by 2025. The data reflects trends such as efficiency improvements, demand growth, and advancements in automation technologies.

Market Analysis: Projected Growth Rates for Glass Polishing Equipment by 2025

The glass polishing equipment market is witnessing significant growth, driven by increasing demand for precision in glass production processes. As highlighted by current market trends, the global market for glass polishing machines is expected to see substantial expansion, aligning with evolving technological advancements and heightened consumer preferences for quality finishes. By 2025, the anticipated market dynamics suggest a notable increase in adoption, reflecting a broader trend of automation and efficiency within the manufacturing sector.

Data projections indicate an aggressive trajectory for the glass polishing equipment sector, with comprehensive analyses pointing towards a robust CAGR through the decade. The infusion of artificial intelligence and robotics into production lines is expected to enhance productivity and reduce waste, catering to environmental considerations that have become pivotal in industry operations. As businesses increasingly recognize the advantages of investing in advanced polishing technologies, the landscape of the glass industry is poised for transformative growth, emphasizing quality and sustainability as key market drivers through 2025 and beyond.

Key Competitors in the Glass Edge Polishing Machine Market: A Data-Driven Overview

As the glass edge polishing machine market continues to evolve, key competitors are emerging with innovative solutions that cater to the growing demand among manufacturers. Recent industry data indicates a notable shift towards automation and efficiency, with machine features that enhance productivity and reduce operational costs. With market projections suggesting significant growth, it is crucial for stakeholders to stay informed on competitive advancements and market dynamics.

In parallel, the broader stone processing machine market is also exhibiting impressive growth potential, projected to reach a market size of approximately $1.41 billion by 2025 and further expanding to $2.22 billion by 2032, maintaining a compound annual growth rate (CAGR) of 6.7%. This rise reflects increasing investments in machinery that aid in the processing and finishing of stone materials, a trend that is mirrored in the glass industry. Such data-driven insights highlight the competitive landscape where manufacturers in both sectors must continuously innovate to capture market share effectively.

Sustainability Trends Impacting Glass Processing Equipment in the Future

As the glass processing industry evolves, sustainability trends are shaping the future of glass edge polishing machines. With growing awareness of environmental issues, manufacturers are increasingly focusing on developing eco-friendly equipment that minimizes waste and energy consumption. Innovations in machinery design, such as utilizing renewable energy sources and reducing emissions, are becoming essential for companies to stay competitive.

Moreover, the shift towards sustainable practices is influencing consumer preferences, prompting suppliers to adopt greener technologies. This encompasses the use of recycled materials in machine production and the implementation of efficient recycling processes for glass byproducts. By investing in sustainable glass processing equipment, companies not only address regulatory standards but also align with the rising demands of environmentally conscious consumers. The 2025 China Import and Export Fair will showcase these advancements, emphasizing the importance of sustainability in the future of the glass industry.

Explore the Future of Glass Edge Polishing Machines at 2025 China Import and Export Fair: Market Trends and Data Insights

| Market Segment |

2023 Market Size (USD Million) |

2025 Projected Market Size (USD Million) |

CAGR (2023-2025) |

Sustainability Trends Impact |

| Flat Glass Processing |

450 |

600 |

11.2% |

Increased demand for energy-efficient machines |

| Architectural Glass |

350 |

480 |

10.5% |

Focus on sustainable building materials |

| Automotive Glass Processing |

200 |

290 |

13.4% |

Growing trend towards lightweight and recycled materials |

| Specialty Glass |

150 |

230 |

15.1% |

Innovation in sustainable glass coatings |

| Glass Packaging |

300 |

410 |

10.9% |

Shift towards recyclable and eco-friendly packaging |

Home

About Us

Products

UPVC PVC Window Machine

Aluminum Window Machine

Glass Cutting Machine

Glass Edging Machine

Insulating Glass Machine

Glass lifting machine

Glass Washing Machine

Glass Laminating Machine

Glass Sandblasting Machine

Glass Drilling Machine

CNC Glass Working Center

CNC Non-Metal Cutting Machine

The Other Glass Machinery

Application

Download

News

Contact Us

The demand for

The demand for