Technological advancement and rising demand for precision and efficiency have led to drastic changes in the glass processing industry in the last few years. According to the report on the global glass cutting machine market by Research and Markets, it will grow at a CAGR of 7% or more during the period 2023 to 2028. The growth is mainly driven by advances in manual glass cutting machines, which are still very important to small and medium enterprises in need of cost-effective solutions that do not sacrifice quality. With innovations, the manual glass cutting machine industry is introducing more and more additional features such as user-friendly operation, optimized material utilization, and improved safety regulations.

In this evolving scenario, Shandong Eworld Machine Co., Ltd., founded in 2014, holds the leading position. Shandong Eworld, a high and new technology enterprise, specializes in the development and manufacture of a broad spectrum of glass processing machinery, from cutting-edge automatic systems to traditional manual machines. As there is a general push for automation and increased production efficiencies worldwide, an understanding of the recent trends in manual glass cutting machinery is essential for buyers globally. This complete guide will form a basis for knowing future trends, functions, and other considerations of glass cutting machines in 2025, with the goal that global buying clients will be fully equipped to make prudent buying decisions in the so-competitive world of today.

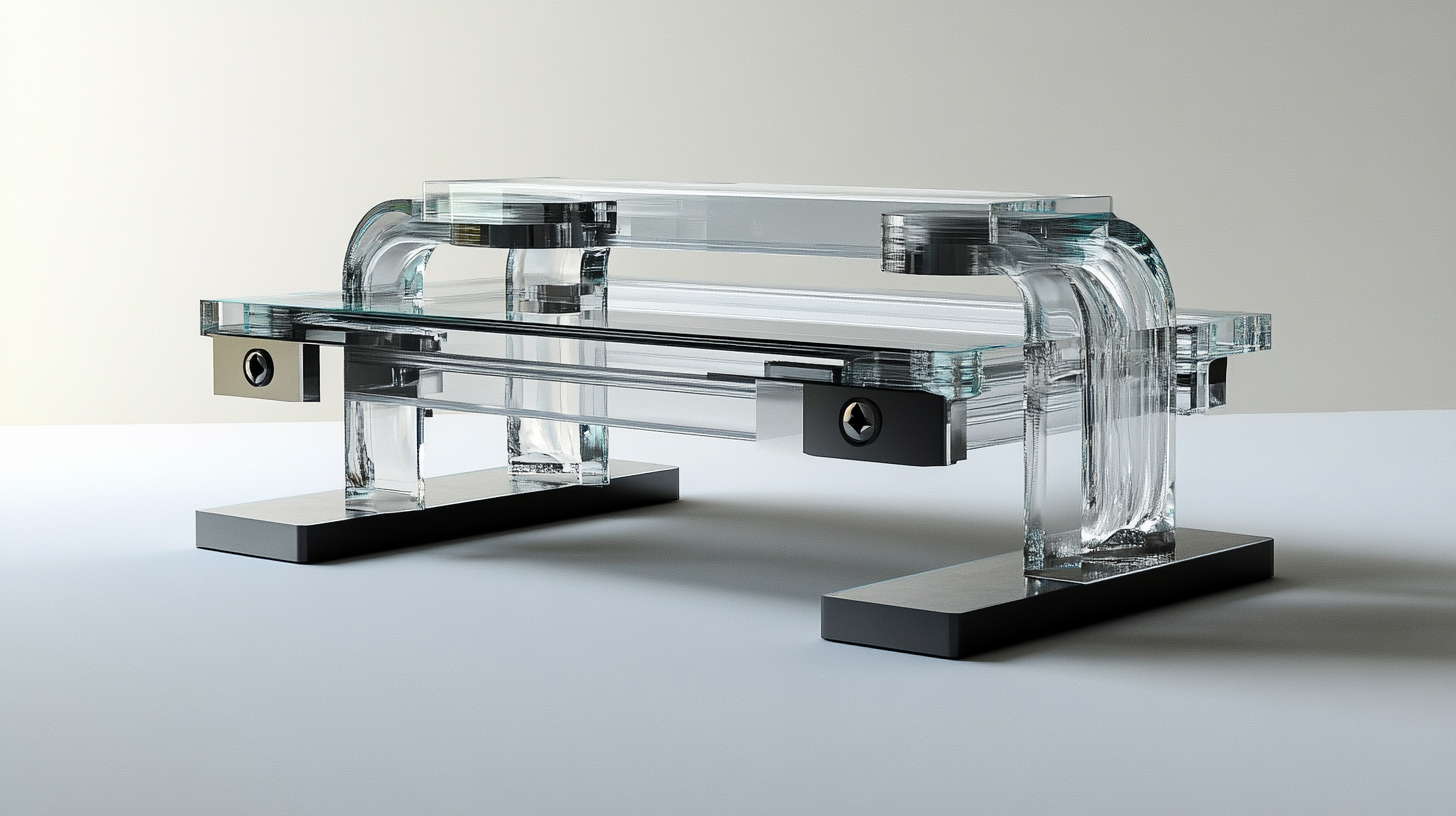

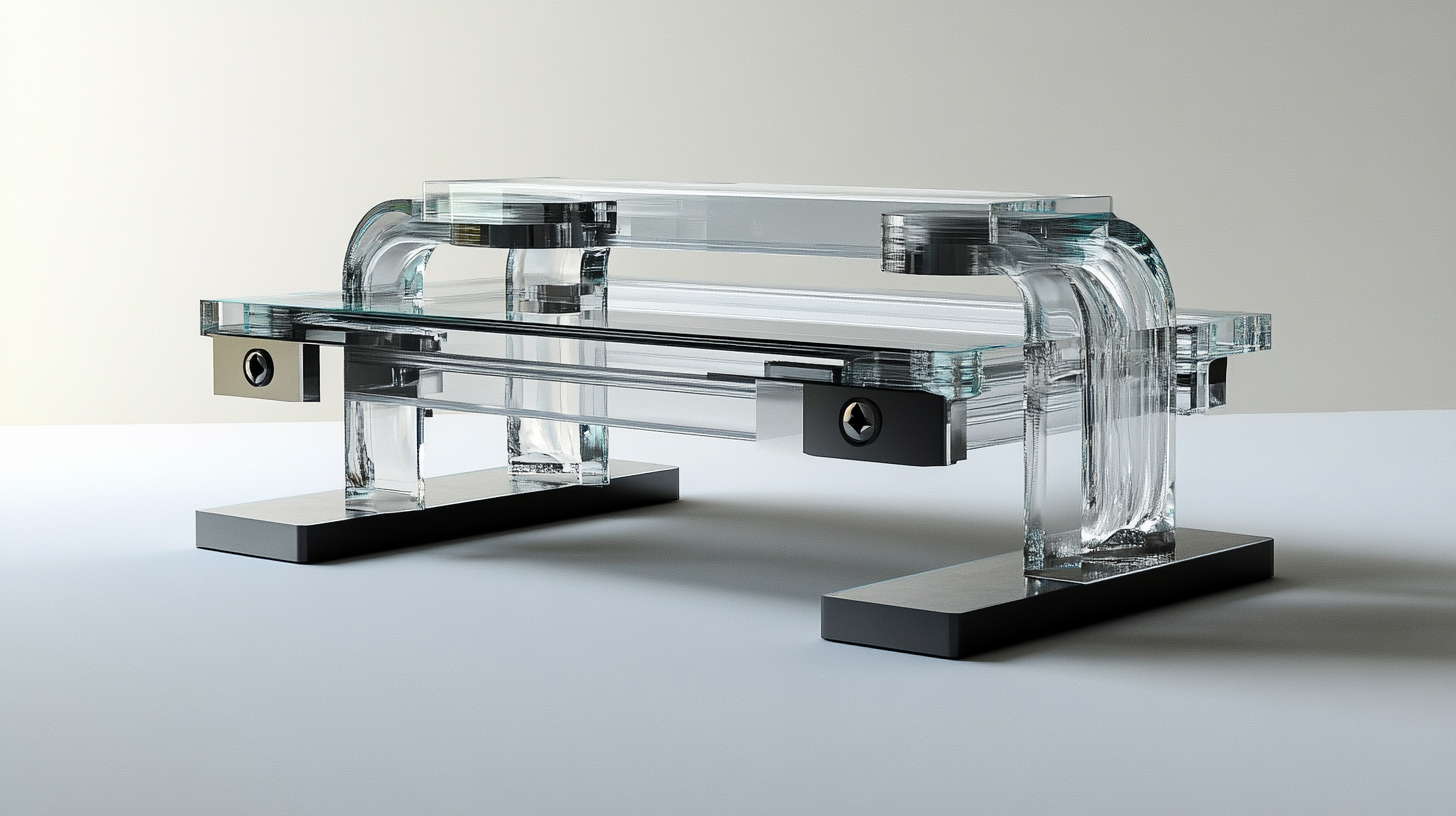

Emerging Technologies Transforming Manual Glass Cutting Machines

2025 will see manual glass cutting machines drastically transformed due to the new emerging technology. The entire evolution of artificial intelligence and machine learning has made such machines not only more efficient but also exceptionally accurate in cutting. Advanced machine learning algorithms, similar to what exists in powerful software solutions such as Azure Machine Learning and Google Cloud Vertex AI, can be included in glass cutting machines for enhancing speed and accuracy of cutting. These technologies can analyze and optimize cutting patterns in real time, ensuring minimal waste and the best possible yield. In addition, their collaboration with the object detection capabilities, which have received a lot of media coverage in AI community discussions lately, will definitely contribute to improved safety and operational effectiveness in glass cutting processes. In combination with the smart sensors that are going to be made available for such machines, an operator will ensure that all critical parameters are continuously monitored and almost eliminate the chances of incidences through loss of material or accidents. This trend is lying along the wide-scale adoption of intelligent robotics across sectors and reflects a future of machines that not only help but also learn and adapt in their working environments. With such innovations, it is worthwhile to note that technology regarding glass cutting machinery is also changing, with reports highlighting advances in high temperature resisting and energy-efficient materials. Such innovations are very critical in supporting operating requirements of next-generation glass cutters, which are quite performance hungry and durability demanding. The industry is thus changing towards more sustainable practices, and these advancements promise a better future for manual glass cutting machines, making them smarter, safer, and greener in terms of operations.

Key Features to Look for in 2025 Glass Cutting Solutions

As a way towards 2025, buyers in the glass cutting industry should focus on certain features that would define the next generation of manual glass cutting machines. It is anticipated that the introduction of other advanced technologies with AI-based processing will reshape the operating manner of these machines. Buyers should consider systems that improve precision and efficiency and allow for any intricate design to be cut with minimal waste and maximum clarity.

Another key consideration is the adaptability of glass cutting machines to various glass types and thicknesses. Since the trend is moving towards lightweight materials with durability, manufacturers must be capable of transforming such machines to serve larger market opportunities. Better cutting solutions, availing of advanced glass substrates, are pivotal to the advancement of the industry, inciting innovation and performance.

On the buyer's end, the priority should also be given to user-friendly interface machines with automation. With these features, these machines will increase the speed of operations while decreasing the training time for new operators, thereby aiding safe practices and improving work efficiency. The demand for flexible and top-quality glass cutting solutions will definitely grow with changing industrial scenarios; hence, these considerations may become crucial for any global buyer in 2025.

Sustainability Trends in Glass Cutting Machine Innovations

Manual glass-cutting machine innovations, with a sustainability trend, take a place at the core in looking into the years to come, especially with respect to the year 2025. The glass industry, too, is making more and more efforts to employ technology that truly reflects being green in manufacturing practices, with an emphasis on the reduction of waste and energy use. Innovations in design and efficiency that boost productivity must also resonate with eco-minded views, and thus ecological footprints will become ever more important for buyers.

Recent innovations, such as automated systems for refined cutting, demonstrate material waste reductions. Automated machines are being developed that are capable of processing huge glass panels efficiently, thus assisting manufacturers to optimize their resources. The shift toward automating the next stage in glass cutting therefore ties into sustainability because it allows optimum raw material usage, thereby reducing the carbon footprint of glass manufacturing.

Additionally, various other companies are innovating with new materials and processes that improve the recyclability of glass products. Such companies will enhance a circular economy by producing machines that not only cut but also aid in recycling the scraps. As such, potential buyers of manual glass cutting machines must stay informed about such sustainability trends, as they are likely to drive higher efficiency and lower costs in their respective operations. With these innovations, the future of glass cutting is bound to become focused not only on precision but also on a more sustainable industry.

Comparative Analysis of Manual vs. Automated Glass Cutting Techniques

Manual glass cutting techniques are, and for long have been, popular in the craft and construction industries. With such techniques, an unmatched precision and control are ensured which very few automated machines can demonstrate. The human touch in manual cutting adds to the artistry of work, but also permits real-time fine adjustment made by the artisans to suit the amazing shapes and sizes taken by the glass pieces. This dexterous skill is perfected over several years and, quite often, is reflected onto the end product making it much more useful for specialty applications.

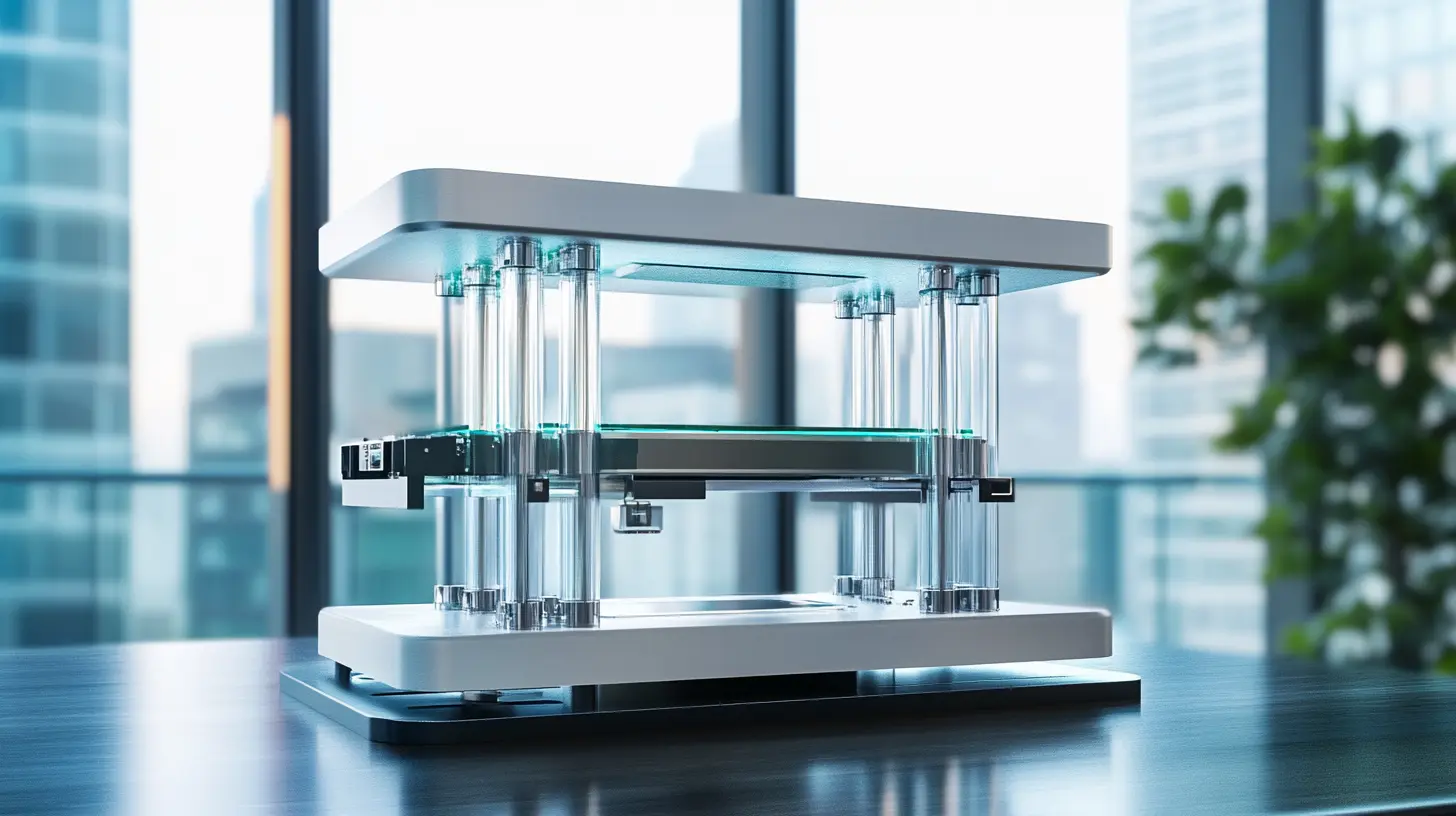

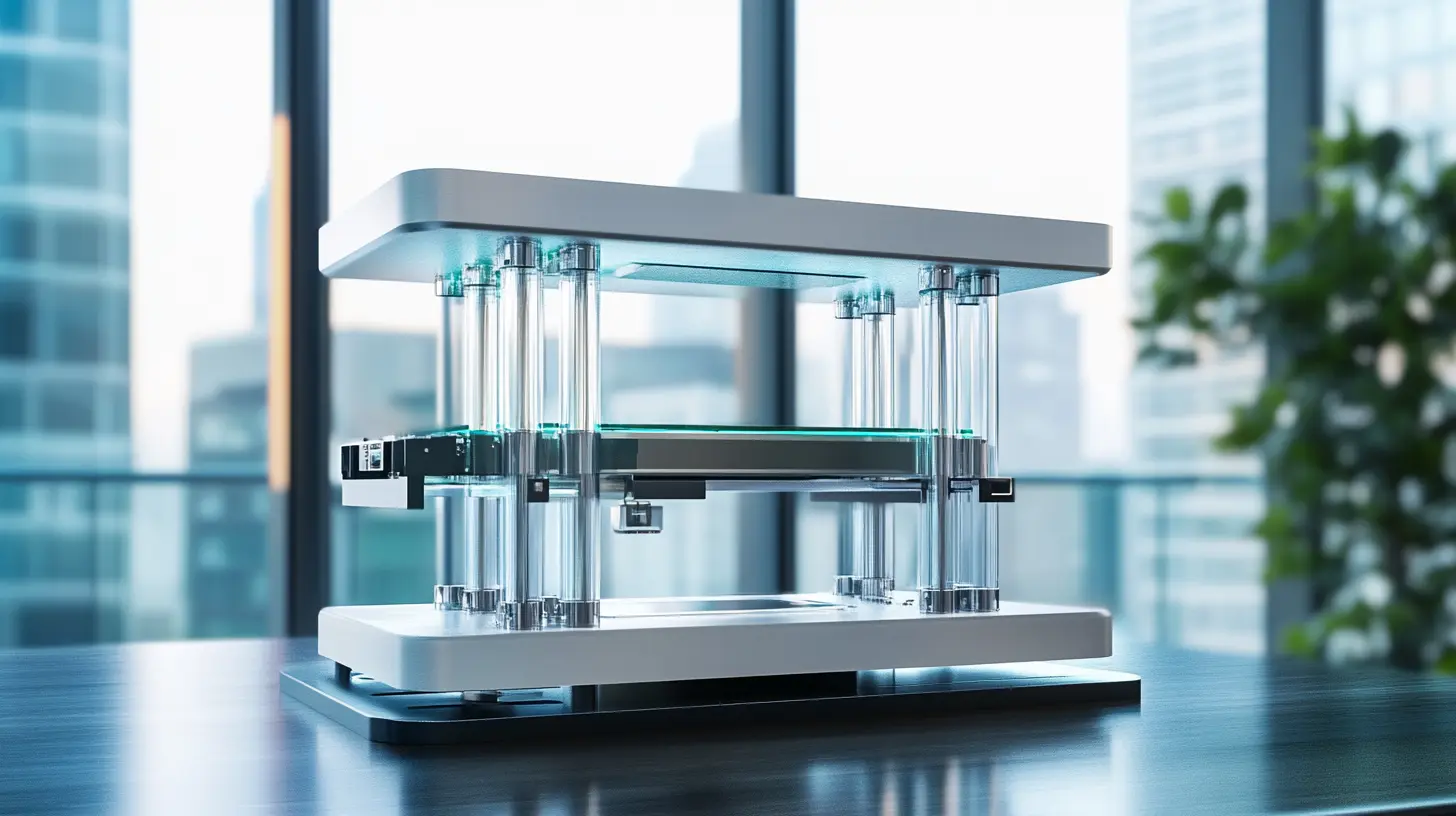

But, the existence of automated glass cutting machines is making speed and efficiency popular among large-scale glass fabricators needing to stimulate production rates. These intelligent machines incorporate sophisticated technology that augments their accuracy and makes them waste-free, thereby allowing them to be operated at high volume with minimum error. But then they may not be that versatile for customized designs involved in manual cutting and it raises some questions on the future of craftsmanship as more and more machines enter the field.

In 2025, the world buyers would be judging between merits and demerits of glass cutting according to their needs and wants. While automation is a great temptation, the timeless quality of manual techniques is such that an amalgam of both may follow. The future may not lie in choosing between methods but rather in finding new ways of combining them so that efficiency and artistry thrive together within the glass-cutting industry.

The Role of Precision Engineering in Modern Glass Cutting Equipment

Precision engineering has assisted in the advancement of manual glass cutting machines, thereby increasing their efficiency and accuracy. Today, cutting solutions are growing in demand due to projections that the global glass market will reach $225 billion by 2025. Reports by various industries show that advancements in manufacturing techniques are leading to cutting solutions that save waste and improve material usage, creating better productivity.

The integration of advanced materials and technologies, including carbide-tipped blades and laser-guided systems, is a testimony to the centrality of precision engineering in contemporary glass cutting tools. Reports indicate that machines with these advancements achieve cutting tolerances as tight as ±0.1 mm, resulting in high-quality output while reducing post-production processing. Such precision becomes critically important in applications where a fraction of a millimeter may translate into considerable loss of material.

As a result of the increasing use of automation and CNC systems in manual cutting, operators are now able to perform intricate cuts with unprecedented ease and accuracy. This has further emphasized the role of precision engineering in enhancing productivity and optimization in reducing costs for the cutting process itself. In the run-up to 2025, these technological advancements ought to be kept in mind by buyers within the global market for the sake of maintaining competitiveness and adapting to changing customer requirements.

Global Market Trends Affecting Glass Cutting Machine Buyers

As the traditional commercial glass-cutting industry prepares for the boom years of 2025, many emerging global trends influencing the buying decisions are seen. According to a new report released by MarketsandMarkets, glass processing will grow by a staggering CAGR of 6.5 percent over the next five years, driven by increasing construction activities and rising demand for energy-efficient solutions. With this prospective growth, buyers will have to evolve with new technologies and innovations in manual glass-cutting machines in their quest to become competitive.

Another trend that influences this market is sustainability. The push for environment-friendly materials prompted manufacturers to develop glass-cutting machines that cater to minimal waste and energy consumption. According to Research and Markets, eco-friendly glass processing tools could account for more than 30 percent of the market by 2025. Thus, buyers may need to look at machines that improve efficiency and at the same time carry their sustainability targets since this will also best meet an increasingly environmentally conscious consumer division.

Automation and smart technology have also influenced the buyers' paradigm shifts in this sector. The latest market disclosures present that incorporating IoT into manual glass cutting machines will considerably improve efficiency in the operations and accuracy of performance. As mentioned in MarketsandMarkets, the boom category within the glass processing industry is anticipated to see a blow-up growth rate of 10% per annum in smart automation, marking proof of a drastic change toward smarter and more adaptable manufacturing processes. Therefore, the buyers are incited to looking for solutions that include these features to prepare their operations for the future.

Expert Insights: Predictions for the Future of Glass Cutting Industry

Even the glass cutting business gradually oozes into metamorphic changes on the very roadmap to 2025. According to ResearchAndMarkets, the global glass cutting machinery market will reach $1.2 billion by 2025, growing with a CAGR of 4.5%. The main propulsion for this growth is technology improvement and the rising demand for precision in architects, autos, and electronics. Manufacturers are investing in better technologies to allow advancement in the operation and efficiency of manual glass cutting machines.

According to experts, one major area of development will be broad-spectrum smart technologies integrated into glass cutting processes. Through the advent of Industry 4.0 and hence the introduction of IoT capabilities, real-time monitoring and analysis of glass cutting processes would optimize production lines thus reducing waste. In fact, a stainless steel survey conducted by TechSci Research disclosed close to 60% of respondents from the industry view that smart machinery would help in unprecedented ways to enhance operational efficiency, reduce costs, and provide higher quality deliverables.

And sustainability is fast becoming a big concern in the glass cutting industry. As per a report by the International Energy Agency (IEA), companies using green technologies are slashing energy use by as much as 30%."Innovation is expected to encompass energy-efficient blades and eco-friendly cutting fluids for manual glass cutting machines to deliver improved eco-responsibility while retaining high productivity. Looking into these forthcoming trends will be crucial for sustaining great purchases as worldwide buyers pursue sustainable solutions."

Navigating Supply Chain Challenges for Glass Cutting Machinery in 2025

The growing market for manual glass cutting machines does not, however, relieve the supply chain navigation challenges for all those global buyers beholden to global supply bases in the year 2025. Such seems to be their anticipation between the Glass Packaging Institute, forecasting the glass utilized in the products worth over $170 billion by 2025 and an annual growth rate estimated at over 3%. The demand here fuels for a ripple effect throughout the supply chain, calling for strategic adaptation of manufacturers and buyers for timely access to equipment.

One of those things negatively impacting the glass cutting machinery market by 2025 would most probably be raw material cost volatility, mainly concerning glass and machining parts. The prices of these materials that have fluctuated significantly, according to the World Trade Organization, have been due to avowed geopolitical tensions and trade disputes, which could further increase production costs for machinery producers. So it makes relationships with good suppliers and consideration of local sourcing options pertinent for buyers to mitigate those risks.

Another thing creating complexity on the supply chain is the increased technology on manual glass cutting machines. These advance the smart aspect of machines like those IoT-enabled; it would really require re-evaluating existing supplier networks and technical capabilities. By 2025 the global smart manufacturing market has been predicted, thus, by MarketsandMarkets, that it would grow to a whopping USD 396 billion, thus, really calling for investments by buyers in supplier education and collaboration in innovation to keep pace and competitive advantages in the market.

FAQS

Buyers should focus on advanced technologies like AI-driven processing capabilities, adaptability to various glass types and thicknesses, user-friendly interfaces, and automation features to enhance precision and efficiency.

Precision engineering significantly enhances the efficiency and accuracy of glass cutting machines, allowing for tighter cutting tolerances (up to ±0.1 mm) and boosting overall productivity while minimizing waste.

The global glass market is projected to reach approximately $225 billion by 2025, with a demand for glass products expected to exceed $170 billion, growing at over 3% annually.

Challenges include volatility in raw material costs due to geopolitical tensions and trade disputes, which can increase production costs, along with the complexity introduced by technological advancements in machinery.

User-friendly interfaces and automation reduce the learning curve for new operators, leading to safer and more productive working environments, which is increasingly vital as industries evolve.

Automation and computer numerical control (CNC) systems enable operators to execute complex cuts with ease and accuracy, optimizing cutting processes through the use of real-time data and feedback.

Strong relationships with suppliers and local sourcing alternatives are essential for mitigating risk from raw material cost volatility and ensuring timely access to equipment amidst market changes.

Innovations like carbide-tipped blades and laser-guided systems are likely to drive advancements in efficiency and quality, highlighting the importance of investing in modern technologies for competitive advantage.

Innovations in manufacturing techniques that enhance cutting precision help reduce waste and improve material usage, ultimately increasing productivity.

Buyers should invest in supplier education and collaboration to keep pace with smart technology advancements and maintain a competitive edge in the evolving glass cutting market.

Home

About Us

Products

UPVC PVC Window Machine

Aluminum Window Machine

Glass Cutting Machine

Glass Edging Machine

Insulating Glass Machine

Glass lifting machine

Glass Washing Machine

Glass Laminating Machine

Glass Sandblasting Machine

Glass Drilling Machine

CNC Glass Working Center

CNC Non-Metal Cutting Machine

The Other Glass Machinery

Application

Download

News

Contact Us