7 Essential Tips for Choosing the Best Manual Glass Cutting Table

In the rapidly evolving glass manufacturing industry, the demand for precision and efficiency has never been higher, and the choice of equipment plays a pivotal role in achieving these goals. A report by the International Glass Association indicates that the global market for glass processing equipment is expected to reach $10 billion by 2025, with manual systems still holding significant prevalence, particularly in artisanal and low-volume production settings. A Manual Glass Cutting Table is critical for achieving clean cuts and maintaining the integrity of the glass, which can directly impact the quality of the final products. As manufacturers strive to enhance productivity while reducing costs, understanding how to select the best manual glass cutting table becomes essential. This blog will outline seven indispensable tips to guide you in making an informed choice that aligns with your operational needs and future growth aspirations, while also celebrating the "world-class manufacturing, Chinese pride, exported globally" ethos that defines the industry today.

Key Considerations for Determining the Right Size of Your Glass Cutting Table

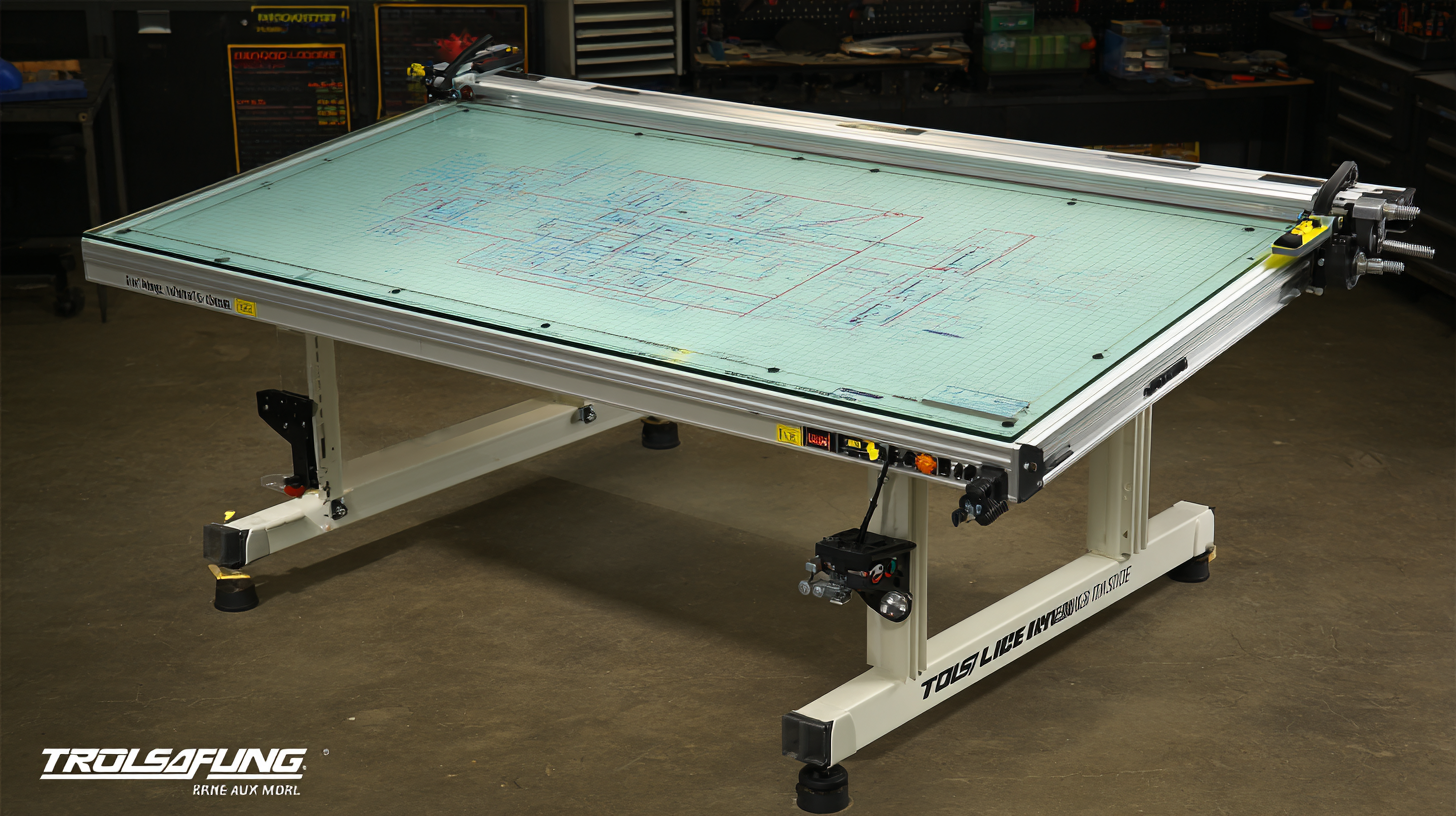

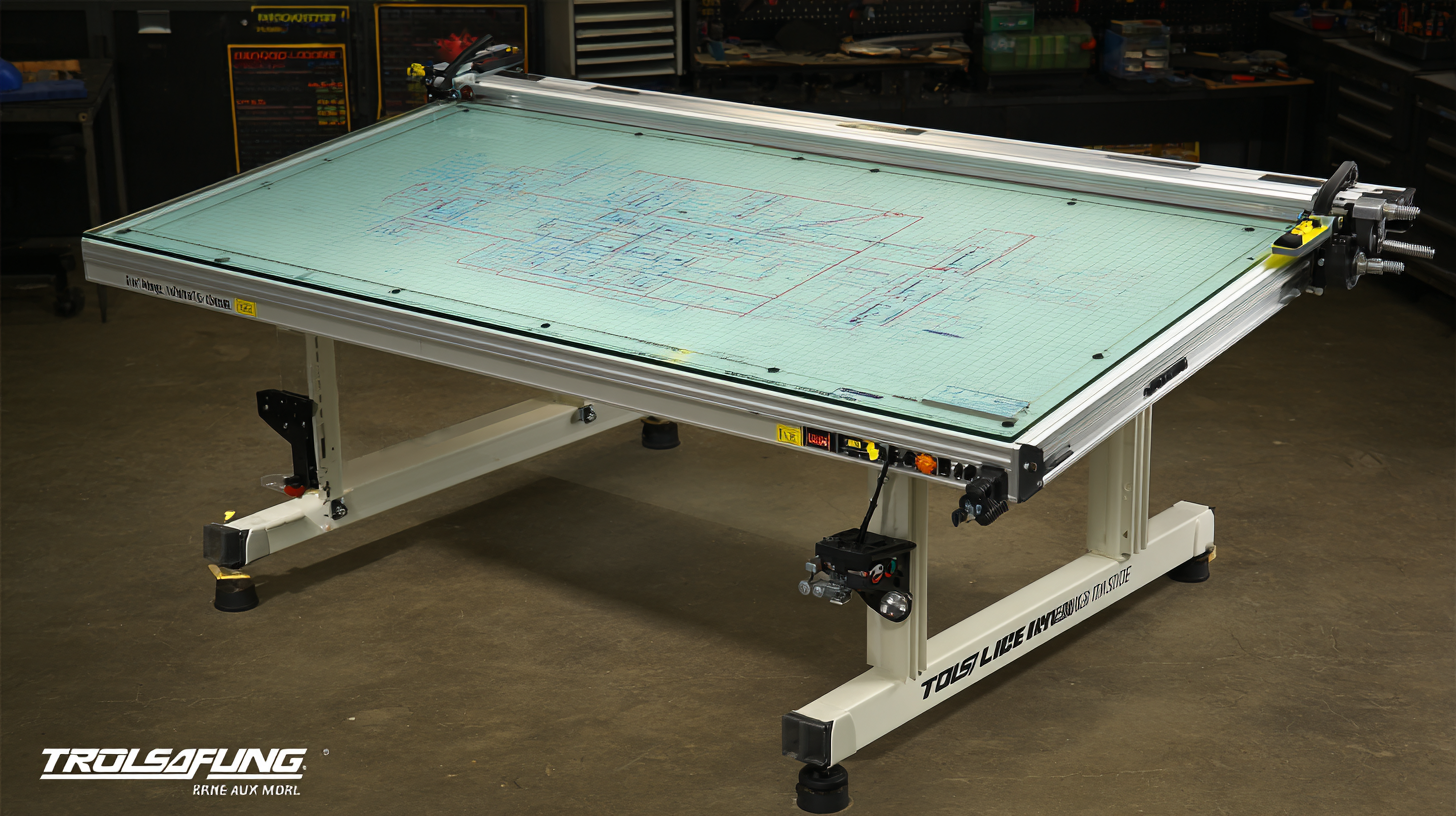

When selecting the right manual glass cutting table, one of the primary considerations is determining the appropriate size. A well-sized cutting table not only enhances efficiency but also ensures safety during the cutting process. According to industry reports, a standard 10 x 6-foot table can accommodate a considerable volume of glass sheets, making it ideal for medium to large-scale operations. However, smaller workshops might benefit from a compact design, typically around 5 x 3 feet, which provides adequate workspace without occupying excessive floor area.

When choosing the size, consider the maximum dimensions of the glass you commonly work with. Tip: Always add a few extra inches to your calculated dimensions to allow for maneuverability and occasional larger projects. It's also vital to think about the workflow around the table; adequate space around it can lead to improved productivity. Another essential factor is the height of the table; it should be comfortable for operators to minimize strain—an ergonomic height usually ranges between 34 to 36 inches from the floor.

It’s important to evaluate your workspace limitations and future growth. As per a recent survey, nearly 30% of glass-cutting businesses reported needing to upgrade their tables within just a few years due to increased demand. Tip: When in doubt, opt for a larger size to accommodate potential expansion in your projects, and ensure versatility to adapt to various glass types and sizes you might encounter.

Understanding the Importance of Material Quality in Glass Cutting Tables

When selecting a manual glass cutting table, understanding the importance of material quality cannot be overstated.

The durability and performance of the table largely depend on the materials used in its construction.

High-quality materials ensure that the table can withstand the rigors of glass cutting without warping, bending, or suffering from wear and tear.

For instance, tables made from sturdy aluminum or reinforced steel not only provide stability but also enhance precision during cuts, allowing for clean and accurate edges.

In addition to the structural integrity, the surface material of the cutting table plays a critical role in the cutting process.

A surface that is too soft may cause uneven cuts, while one that is excessively hard might lead to chipping or cracking of the glass.

Therefore, opting for tables with specialized surfaces, such as tempered or laminated materials, can significantly improve the cutting experience.

Overall, investing in a high-quality manual glass cutting table made from premium materials is essential for anyone looking to achieve professional results and maintain a safe working environment.

Essential Features to Look For in a Manual Glass Cutting Table

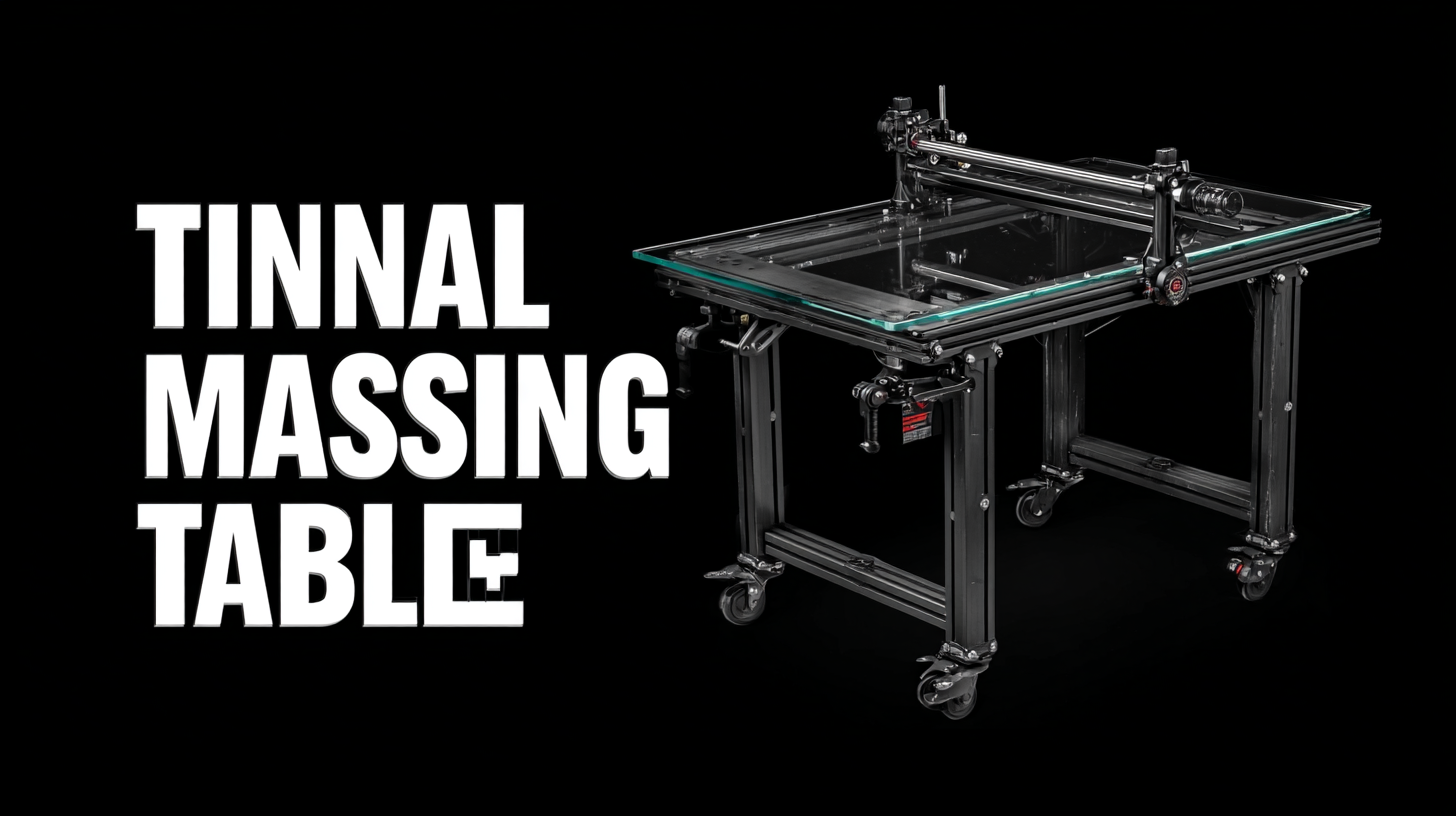

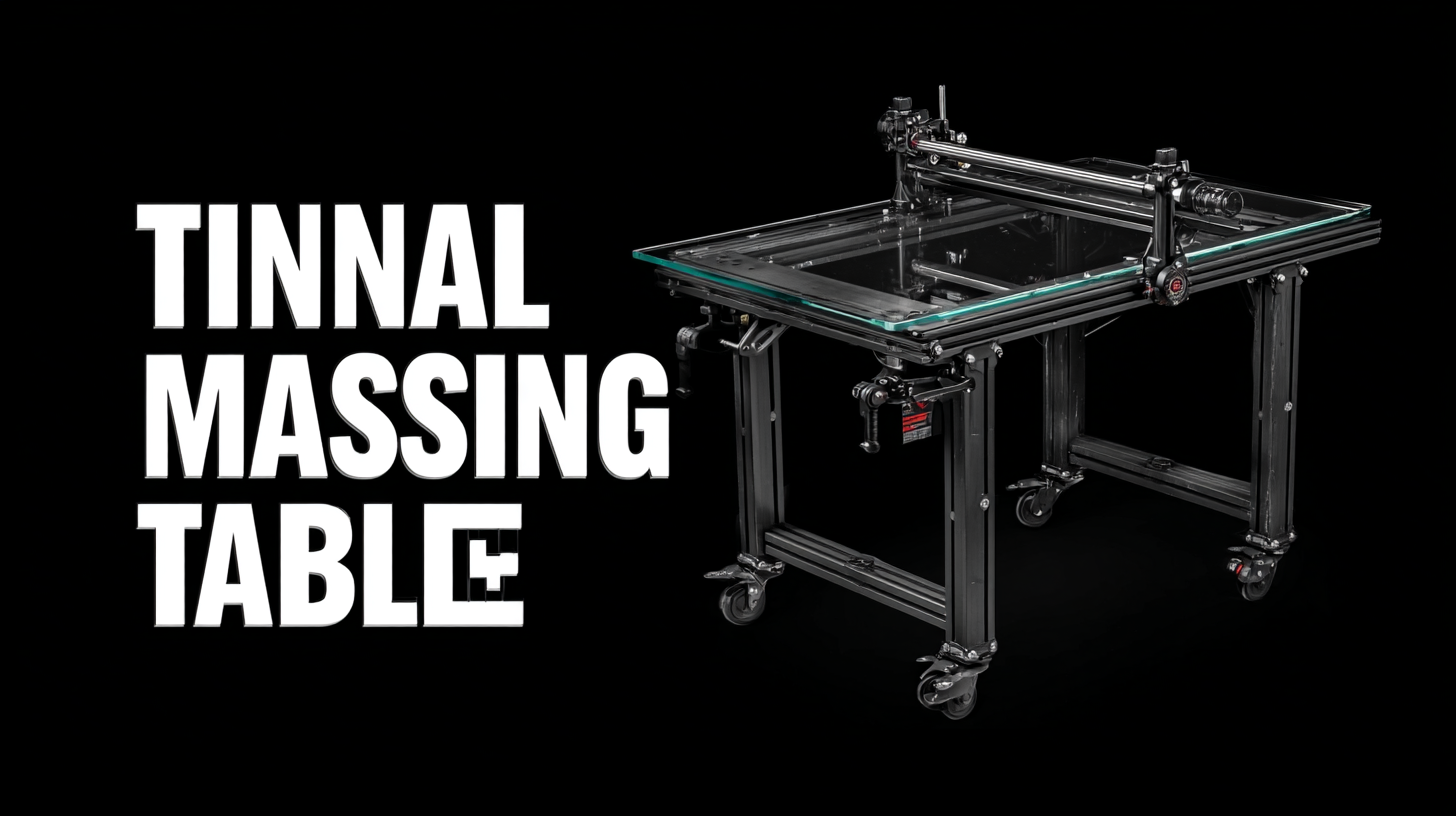

When selecting a manual glass cutting table, several essential features should be at the forefront of your decision-making process. First and foremost, look for a sturdy, stable construction. A table that can withstand the weight and pressure of glass cutting is vital to produce clean, precise cuts.

Materials such as steel or heavy-duty aluminum offer the necessary durability, ensuring that the table won't wobble during the cutting process, which can lead to inaccuracies.

Another significant feature to consider is the size of the cutting surface. A generous workspace allows you to handle larger sheets of glass and provides ample room for maneuvering your tools. Additionally, adjustable cutting angles can greatly enhance your ability to create custom shapes and sizes. A good cutting table will also include built-in measuring tools and guides, which can streamline your workflow and reduce the risk of errors. Finally, check for portability options if you need to move your table frequently; features like foldability or lightweight materials can make transport much easier.

Evaluating Cost vs. Value: Budget-Friendly Tips for Glass Cutting Tables

When selecting a manual glass cutting table, understanding the balance between cost and value is crucial. A budget-friendly option doesn’t necessarily mean compromising on quality. Start by identifying your specific needs. Are you a hobbyist or a professional? Your usage will dictate the features you should consider. Look for tables made from durable materials that offer stability and precision, even if it means investing a little more upfront. Often, spending a bit extra on a reliable table can save you costs in the long run by enhancing your work's accuracy and reducing wastage.

Another factor to evaluate is the table's additional features. Some models offer adjustable cutting heights, integrated rulers, or clamps, which can significantly increase efficiency. While these features might raise the initial cost, they provide value by improving your workflow and ensuring better cuts. Research and compare different options, as a slightly higher price tag can lead to enhanced functionality that justifies the investment. Ultimately, finding the right manual glass cutting table involves weighing its long-term benefits against your budget constraints.

Safety Features: Ensuring a Secure Cutting Environment for Glass Projects

When selecting a manual glass cutting table, safety features should be at the forefront of your decision-making process. A secure cutting environment not only protects you but also ensures accurate results. Look for a table with a sturdy frame and non-slip surface to minimize the risk of accidents. Additionally, consider tables equipped with safety guards that prevent glass shards from scattering, which can be a significant hazard during cutting.

Another crucial aspect is the presence of adjustable clamps or supports. These allow you to secure your glass firmly in place, reducing movement while you work and enhancing safety. Furthermore, ensure that the table has appropriate safety certifications, indicating that it has undergone rigorous testing for durability and stability. Investing in a quality cutting tool with these essential safety features can make all the difference in creating a safe and efficient workspace for your glass projects.

Lastly, don't overlook the importance of personal protective equipment (PPE). No matter how secure your glass cutting table is, wearing safety goggles and cut-resistant gloves can provide an additional layer of protection. Prioritizing safety in your workspace helps foster creativity and productivity without compromising your well-being.

7 Essential Tips for Choosing the Best Manual Glass Cutting Table - Safety Features: Ensuring a Secure Cutting Environment for Glass Projects

| Feature |

Description |

Importance |

| Safety Guards |

Transparent guards that prevent accidental contact with the cutting blade. |

High - reduces risk of injury. |

| Non-Slip Surface |

A textured surface that keeps the glass in place during cutting. |

Medium - enhances stability. |

| Cutting Accuracy |

Features such as guided rails that assist in making precise cuts. |

High - ensures quality of the cut. |

| Portability |

Lightweight design for easy transport between job sites. |

Medium - convenience for users. |

| Adjustable Height |

Allows the user to set the table to a comfortable working height. |

High - reduces strain and fatigue. |

| Cutting Tools Storage |

Built-in compartments for safe storage of cutting tools. |

Medium - keeps workspace organized. |

| Durability |

Constructed from sturdy materials to withstand heavy use. |

High - ensures long-term investment. |

Home

About Us

Products

UPVC PVC Window Machine

Aluminum Window Machine

Glass Cutting Machine

Glass Edging Machine

Insulating Glass Machine

Glass lifting machine

Glass Washing Machine

Glass Laminating Machine

Glass Sandblasting Machine

Glass Drilling Machine

CNC Glass Working Center

CNC Non-Metal Cutting Machine

The Other Glass Machinery

Application

Download

News

Contact Us