Why Choose CNC Machines for Glass Processing: Key Benefits Explained

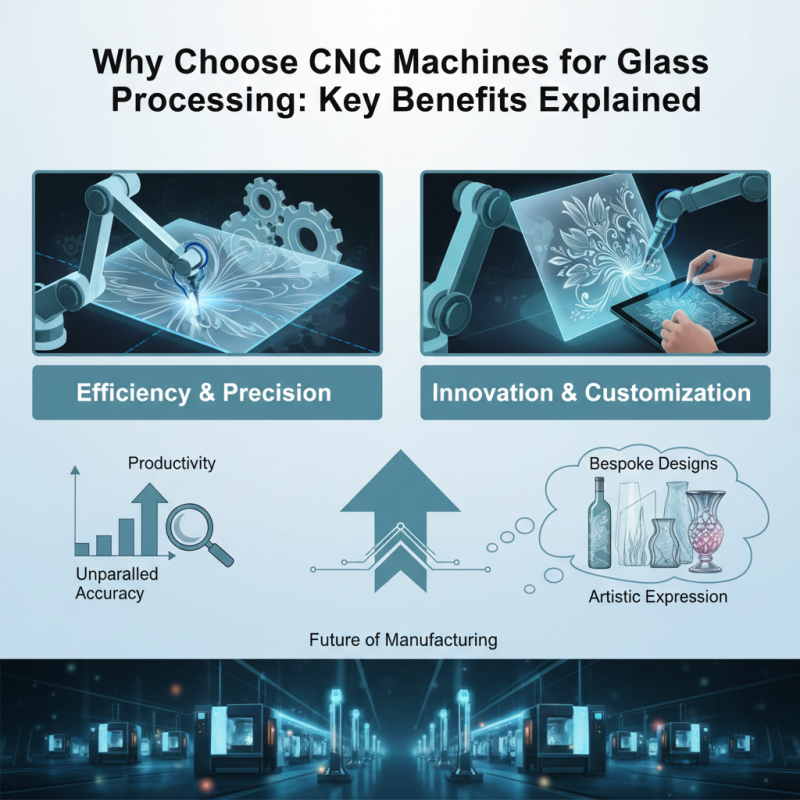

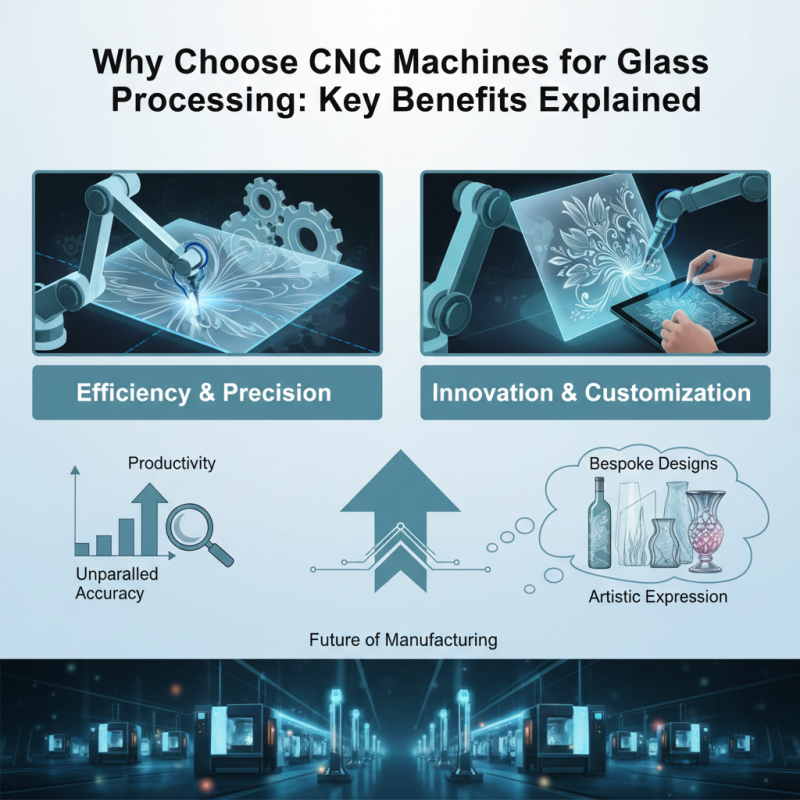

In the realm of modern manufacturing, the precision and efficiency of CNC machines have revolutionized various industries, particularly in the realm of glass processing. As John Smith, a leading expert in CNC Machine Glass Processing, aptly stated, “The advent of CNC technology has not only increased productivity but has also pushed the boundaries of creativity in glass design.” This statement underscores the significant advantages that CNC machines offer for glass processing, making them an essential investment for manufacturers aiming to enhance both their output and the intricate designs they can achieve.

The growing demand for customized glass products has necessitated innovative solutions that can meet the intricate specifications of clients while ensuring seamless production processes. CNC Machine Glass Processing provides unparalleled accuracy, allowing for detailed cutting, engraving, and shaping of glass materials. By leveraging advanced software and precision tools, manufacturers can produce exceptionally detailed designs that were previously unattainable through traditional methods. This capability not only streamlines the manufacturing process but also opens new avenues for artistic expression, catering to the increasing market for bespoke glass items.

As we delve deeper into the key benefits of CNC machines in glass processing, it becomes evident that their role extends far beyond mere efficiency. They empower manufacturers to push the limits of design while maintaining consistent quality and reducing waste. The integration of CNC technology into glass processing is not merely a trend; it is a pivotal step towards the future of glass manufacturing.

Advantages of CNC Machines in Glass Processing

CNC (Computer Numerical Control) machines have revolutionized the glass processing industry by offering precision, efficiency, and versatility. One of the primary advantages of using CNC machines for glass processing is their ability to produce intricate designs and shapes that were previously challenging to achieve with manual methods. The automation provided by CNC technology minimizes human error and allows for consistent quality across batches, ensuring that each piece meets the exact specifications required.

Another key benefit of CNC machines is their efficiency. These machines can operate continuously, which drastically reduces production time compared to traditional methods. This increase in productivity not only saves time but also reduces labor costs, allowing businesses to allocate resources more effectively. Additionally, CNC machines can handle a variety of glass types and thicknesses, making them adaptable to various project needs.

Tips: When considering CNC machines for glass processing, ensure that you invest in proper training for your operators. Familiarity with the software and machine operation will enhance productivity and safety. It's also beneficial to regularly maintain the CNC equipment to ensure optimal performance and longevity, as neglect can lead to costly downtime or repairs.

Why Choose CNC Machines for Glass Processing: Key Benefits Explained

| Key Benefits |

Description |

| Precision |

CNC machines offer high precision and accuracy, ensuring each cut and design is executed to exact specifications. |

| Efficiency |

They significantly reduce production time, allowing for faster turnaround and higher volume outputs. |

| Complex Designs |

CNC technology can easily handle complex designs and intricate shapes that are difficult with traditional methods. |

| Material Variety |

These machines can work with a variety of glass types and thicknesses, increasing versatility across projects. |

| Reduced Waste |

CNC machines optimize material usage, which leads to less waste and lower overall production costs. |

| Automation |

Automation capabilities allow for continuous production with minimal human intervention, improving consistency and safety. |

| Flexibility |

CNC machines can be easily reprogrammed for different jobs, providing flexibility to adapt to project variations. |

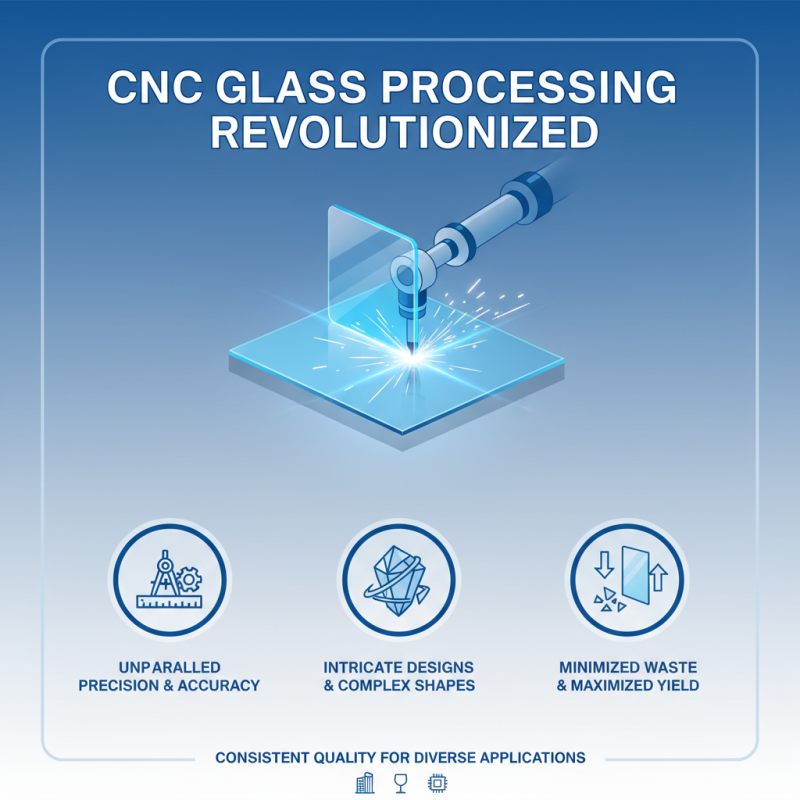

Precision and Accuracy in Glass Cutting and Shaping

CNC machines have revolutionized the way glass is processed, offering unparalleled precision and accuracy that traditional methods cannot achieve. This technology allows for intricate designs and complex shapes to be cut and shaped from glass with an exactness that minimizes waste and maximizes yield. With the capability to produce precise measurements consistently, CNC machines ensure that each piece of glass meets stringent specifications, making them ideal for various applications, from architectural elements to intricate art pieces.

The use of CNC technology in glass processing also enhances efficiency in production. Automated processes reduce the likelihood of human error, ensuring that each cut is uniform and replicable. This level of control allows for the production of high-quality glass products in a shorter time frame, catering to the increasing demands of the market. As a result, businesses can deliver tailored solutions to their clients while maintaining the highest standards of quality, making CNC machines an indispensable tool in the glass industry.

Efficiency and Speed: Enhancing Glass Production

Efficiency and speed are two cornerstone advantages of utilizing CNC machines in glass processing, revolutionizing the way manufacturers approach production. By automating the cutting, shaping, and finishing processes, CNC machinery minimizes human error and optimizes operational workflows. This results in significantly reduced cycle times, allowing for quicker turnaround on projects and enhanced productivity. Manufacturers can process larger volumes of glass with precision, meeting the increasing demand in various sectors, such as architecture and automotive industries.

Moreover, with the rapid advancements in technology, modern CNC machines offer enhanced features that streamline production further. High-speed lasers and automated tool changes ensure that tasks are completed swiftly without sacrificing quality. Additionally, the ability to program complex designs with ease means that intricate patterns can be executed in a fraction of the time it would take using traditional methods. This agility not only fosters a more responsive supply chain but also permits greater flexibility in design, which can attract a broader clientele seeking customized glass solutions.

Efficiency and Speed in Glass Processing with CNC Machines

Customization Capabilities with CNC Technology

CNC technology has revolutionized glass processing by offering unrivaled customization capabilities. Unlike traditional methods, CNC machines allow for precise control over every aspect of the glass fabrication process, enabling manufacturers to produce intricate designs that were previously unattainable. With advanced programming and modeling software, CNC machines can accommodate unique shapes, sizes, and patterns, ensuring that each piece of glass meets specific client requirements. This level of customization not only enhances aesthetic appeal but also greatly expands the design possibilities for architects and interior designers.

Moreover, CNC machines streamline the production process, reducing lead times while maintaining high-quality standards. Automated settings facilitate rapid adjustments, allowing for quick transitions between different designs or specifications without sacrificing accuracy. This flexibility is particularly beneficial for businesses looking to fulfill diverse customer demands, as it empowers them to respond swiftly to market trends. Overall, the integration of CNC technology in glass processing paves the way for innovative solutions that cater to the evolving needs of the industry.

Cost-Effectiveness and Waste Reduction in Glass Fabrication

When it comes to glass fabrication, CNC machines offer significant advantages in cost-effectiveness and waste reduction. Traditional methods often involve high labor costs and significant material waste, whereas CNC technology automates the cutting and shaping processes with precision. This means less material is lost during production, directly impacting the bottom line by lowering the costs associated with raw materials. By streamlining operations and minimizing manual errors, businesses can improve their overall efficiency.

**Tips:** To maximize your savings, consider optimizing your production schedule to fully utilize CNC capabilities. Transitioning to CNC machines can also lead to economies of scale; as production increases, the fixed costs are spread across a larger number of units, reducing the cost per item. Additionally, investing in proper training for your operators can enhance efficiency and ensure that the machines are used to their full potential.

Moreover, CNC machines can facilitate the recycling of glass by efficiently cutting scrap to size for reuse. By transforming leftover materials into usable shapes, companies can significantly lower the costs related to waste disposal. This not only contributes to a more sustainable practice but also boosts profitability by turning what would otherwise be considered waste into valuable product.

**Tips:** Regular maintenance of CNC machines can prevent costly downtime and ensure they operate at peak efficiency. Moreover, keeping an accurate inventory of glass materials can help in planning for production runs, thereby reducing surplus and optimizing resource usage.

Home

About Us

Products

UPVC PVC Window Machine

Aluminum Window Machine

Glass Cutting Machine

Glass Edging Machine

Insulating Glass Machine

Glass lifting machine

Glass Washing Machine

Glass Laminating Machine

Glass Sandblasting Machine

Glass Drilling Machine

CNC Glass Working Center

CNC Non-Metal Cutting Machine

The Other Glass Machinery

Application

Download

News

Contact Us