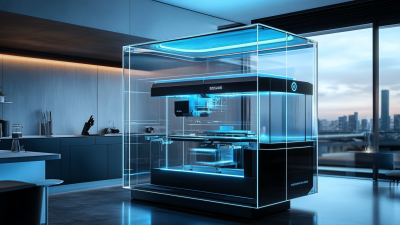

7 Compelling Reasons to Choose Cnc Machine Glass Cutting for Your Business Success

In today's competitive manufacturing landscape, businesses are constantly seeking innovative solutions to enhance efficiency and quality. One such advancement is "Cnc Machine Glass Cutting," which has revolutionized the glass processing industry. According to the Global Glass Cutting Machine Market Report, the industry is projected to grow at a CAGR of 6.2% from 2021 to 2026, driven by increasing demand for precision and speed in glass fabrication. Utilizing CNC technology not only minimizes material waste but also ensures higher accuracy than traditional methods. As businesses aim to meet ever-evolving consumer demands, adopting Cnc Machine Glass Cutting becomes not just an option but a necessity for success. This article delves into seven compelling reasons why integrating CNC glass cutting into your operations can significantly enhance your business's productivity and profitability.

Advantages of Precision and Accuracy in CNC Glass Cutting

The growing demand for precision in manufacturing has positioned CNC machine glass cutting as an indispensable tool for businesses aiming for success.

CNC (Computer Numerical Control) technology allows for unparalleled accuracy, achieving tolerances as tight as ±0.01 mm. According to a report from MarketsandMarkets, the CNC machine market is anticipated to reach USD 117.8 billion by 2026, driven by the need for enhanced precision in various industries, including automotive, aerospace, and glass fabrication.

One of the key advantages of CNC glass cutting is its ability to produce consistently high-quality results with minimal waste. Advanced software enables manufacturers to optimize cutting paths, reducing raw material waste by up to 30%. This precision not only minimizes costs but also ensures that the final product meets exact specifications.

The precision offered by CNC technology is critical, with a study from the National Institute of Standards and Technology highlighting that even slight deviations in glass cutting can lead to significant performance issues in applications such as architecture and automotive design. Adopting CNC glass cutting can thus provide a competitive edge, ensuring that businesses can deliver superior products that meet the increasing demands of quality-conscious consumers.

Enhancing Production Efficiency through Automated Processes

Automated processes play a crucial role in enhancing production efficiency, particularly within industries that require precision and speed. CNC machine glass cutting exemplifies this by streamlining operations, minimizing human error, and increasing output. By automating this process, businesses can significantly reduce labor costs and ensure consistent quality in their products.

Tip: When considering automation, invest in training for your staff to effectively manage and troubleshoot the new systems. This ensures a smooth transition and maximizes the benefits of automation.

Moreover, the integration of advanced technologies, such as RFID, further enhances production capabilities. RFID can optimize inventory management and traceability in complex manufacturing processes, allowing businesses to respond quickly to market demands. This added layer of automation not only enhances efficiency but also boosts the overall smart image of your products.

Tip: Monitor key performance indicators (KPIs) to assess the impact of automation on production. This will help you identify areas for improvement and adjust your strategy accordingly, ensuring sustained business growth in an increasingly competitive market.

Cost-Effectiveness: Reducing Waste and Maximizing Resources

Cost-effectiveness is becoming an essential criterion for businesses aiming for long-term success, especially in the competitive landscape of glass cutting. Utilizing CNC machine glass cutting technology significantly reduces waste and optimizes resource usage. Traditional cutting methods often result in a substantial amount of leftover materials, leading to increased operational costs. By switching to CNC machines, businesses can achieve precise cuts that minimize off-cuts and resource wastage, thereby maximizing their material efficiency.

Moreover, the ability to produce high-quality finished products quickly without compromising on accuracy can further enhance a company's profitability. CNC technology automates the cutting process, leading to consistent results and reducing the likelihood of human error. This not only saves time but also allows companies to allocate their workforce to other critical tasks, increasing overall productivity. As businesses increasingly prioritize sustainability and cost-saving measures, CNC machine glass cutting stands out as a logical and beneficial choice, setting the stage for enhanced operational performance and financial success.

Versatility of CNC Machines for Various Glass Types and Thicknesses

In today's competitive landscape, the versatility of CNC machines in glass cutting cannot be overstated. According to a recent report by MarketsandMarkets, the global CNC machine market is expected to grow at a compound annual growth rate (CAGR) of 6.0% from 2021 to 2026, driven in part by the rising demand for precision in glass applications. CNC machines can easily accommodate various types of glass, including tempered, laminated, and even specialized decorative glass, making them an invaluable asset for businesses catering to diverse client needs.

Moreover, CNC technology allows for precise adjustments in cutting thickness, ensuring tailored solutions for projects that require specifications ranging from a mere few millimeters to more extensive slabs. According to a study by Grand View Research, the increasing applications of glass in construction—projected to rise by 4.5% annually—highlight the necessity for adaptable cutting technologies. This adaptability not only enhances production efficiency but also reduces material waste, driving down costs while improving the environmental footprint of glass manufacturing processes. By embracing CNC machine glass cutting, businesses can position themselves to meet the evolving demands of the market effectively.

Streamlining Design Options with Customization Capabilities

The advancement of CNC machine glass cutting technology has revolutionized the way businesses approach custom design projects. With the ability to streamline and enhance design options, CNC machines allow for unparalleled customization, enabling manufacturers to meet specific client demands quickly and efficiently. According to a report by MarketsandMarkets, the global CNC machine market is projected to reach $116.08 billion by 2025, growing at a CAGR of 6.3%. This trend indicates a robust demand for innovative and tailored solutions across industries, making CNC machines essential tools for any business seeking a competitive edge.

Customization capabilities are a significant benefit of CNC machine glass cutting, as they allow businesses to produce intricate designs and shapes that were previously difficult or impossible to achieve. By utilizing advanced software and precision cutting techniques, companies can effortlessly create personalized products that cater to diverse customer needs. Research from Technavio highlights that the growing trend for customization is expected to contribute to an annual market growth rate of 4% in the glass cutting industry until 2024. This increasing preference for tailored solutions underscores the importance of incorporating CNC technology into business operations, where creativity and efficiency go hand in hand.

7 Compelling Reasons to Choose CNC Machine Glass Cutting for Your Business Success

| Reason |

Description |

Benefit |

| Precision Cutting |

CNC machines provide high precision in glass cutting, ensuring accurate dimensions. |

Reduces material waste and increases product quality. |

| Customization |

Ability to create custom designs and shapes easily. |

Enhances customer satisfaction through tailored solutions. |

| Speed |

CNC cutting is faster than traditional methods. |

Increases productivity and reduces lead times. |

| Versatility |

Can handle various glass types and thicknesses. |

Expands the range of products and services offered. |

| Reduced Labor Costs |

Automation reduces the need for manual labor. |

Lowers overhead costs associated with staffing. |

| Consistency |

Delivers consistent cuts across multiple pieces. |

Ensures product uniformity and reduces quality issues. |

| Enhanced Safety |

CNC machines are equipped with safety features that minimize risks. |

Protects workers and reduces injury-related expenses. |

Home

About Us

Products

UPVC PVC Window Machine

Aluminum Window Machine

Glass Cutting Machine

Glass Edging Machine

Insulating Glass Machine

Glass lifting machine

Glass Washing Machine

Glass Laminating Machine

Glass Sandblasting Machine

Glass Drilling Machine

CNC Glass Working Center

CNC Non-Metal Cutting Machine

The Other Glass Machinery

Application

Download

News

Contact Us