What is CNC Machine Glass Cutting and How Does It Work?

CNC Machine Glass Cutting is revolutionizing the glass manufacturing industry. According to a recent report by Grand View Research, the CNC glass cutting machine market is projected to reach $2 billion by 2026. This growth is fueled by the increasing demand for precise glass parts in architecture, automotive, and electronics sectors.

Expert Alex Johnson, a leading figure in CNC technology, emphasizes, "The efficiency and accuracy of CNC Machine Glass Cutting are unmatched." His insights highlight the precision offered by CNC systems, which can enhance production efficiency. However, there are challenges in adopting this technology fully. Companies must invest in training and proper maintenance to ensure optimal performance.

Despite its benefits, some industries remain hesitant. The initial investment can be daunting. Many businesses struggle with calibrating their machines for specific glass types. As the market evolves, thought leaders will address these issues. Continuous development in CNC technology may help bridge the gap.

What is CNC Glass Cutting?

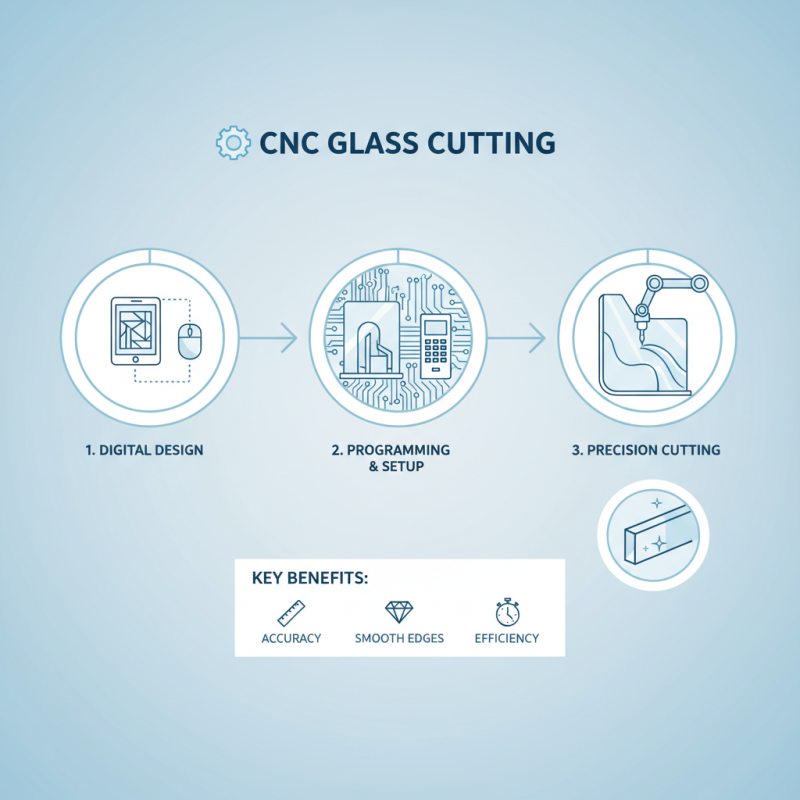

CNC glass cutting utilizes computer numerical control technology to achieve precision. It operates with a machine that follows programmed designs. This method ensures accuracy that manual cutting struggles to match. The process begins with designing the desired shape using CAD software. This design is then translated into machine language.

The CNC machine uses a diamond-tipped cutting tool or laser. Once the program is set, the machine cuts the glass smoothly and accurately. This workflow minimizes human error. However, challenges can arise, such as misalignment of tools or software glitches. Operators must double-check their settings, as mistakes can be costly.

Despite its benefits, CNC glass cutting is not without flaws. It requires expensive equipment and skilled operators. Not every design can be efficiently executed. Some complex shapes might need manual adjustments. Thus, while CNC offers advantages, it demands careful consideration and continuous learning.

CNC Glass Cutting Efficiency Over Different Glass Thicknesses

This bar chart illustrates the efficiency of CNC glass cutting across different glass thicknesses. As shown, the efficiency decreases as the thickness of the glass increases, demonstrating the challenges of cutting thicker materials.

The Components of a CNC Glass Cutting Machine

CNC glass cutting machines are essential tools in various industries. Their design comprises key components that function collaboratively. At the core of the machine is the CNC control unit. This unit allows precise programming of cuts. Operators input specific dimensions, ensuring accuracy.

Another significant component is the cutting head. It contains diamond blades or lasers that slice through glass effortlessly. The material is secured on a flat surface. This helps maintain stability during the cutting process. The motion system ensures smooth movement across the glass, enhancing the cutting precision.

Tip: Always double-check your measurements. Small errors can lead to large discrepancies in glass pieces.

Maintenance is crucial for these machines. Regularly inspect the blades and moving parts. A well-maintained machine reduces the risk of mistakes. Dust and debris can accumulate, affecting performance. Cleaning the work area helps ensure quality cuts.

Tip: Consider using protective gears. Glass cutting can produce sharp shards, posing safety risks. It's better to invest in safety than to deal with injuries later.

What is CNC Machine Glass Cutting and How Does It Work? - The Components of a CNC Glass Cutting Machine

| Component |

Function |

Material |

Importance |

| CNC Controller |

Interprets design files and sends commands to the machine |

Electronics |

Essential for precise operation |

| Cutting Head |

Houses the cutting tool, making precise cuts |

Aluminium or Steel |

Critical for cut quality |

| Movement System |

Moves the cutting head along the X, Y, Z axes |

Steel Rails |

Ensures accuracy and smooth operation |

| Software |

Generates cutting paths and controls the machine |

Digital |

Key to automation and efficiency |

| Safety Enclosures |

Protects operators from hazards |

Acrylic or Metal |

Critical for operator safety |

How CNC Machines Cut Glass: The Process Explained

CNC glass cutting utilizes advanced technology to precisely shape glass. The process begins with a digital design. This design directs the CNC machine on how to cut the glass. A typical CNC machine uses a diamond-tipped cutter due to its hardness. This ensures smooth edges and accuracy.

During the cutting process, the machine moves along the programmed paths. It executes complex shapes with minimal human intervention. Data from the machinery suggests a reduction in waste by up to 20%. The precision of CNC cutting allows for intricate designs that may be challenging with traditional methods. However, some users report difficulties with thicker glass. Adjusting settings for depth can be critical.

**Tip:** It’s always best to test cuts on scrap glass first. This way, adjustments can be made without wasting material.

CNC technology is evolving. Recent reports indicate increased efficiency in mass production. Companies can expect faster turnaround times, reducing labor costs significantly. Yet, operators must remain vigilant. Machine maintenance is essential to avoid unexpected failures. Keeping the equipment in top shape is crucial for continued precision.

Advantages of Using CNC for Glass Cutting

CNC machine glass cutting offers numerous advantages that make it a preferred choice in the industry. One key benefit is precision. With CNC technology, glass pieces can be cut with an accuracy of 0.01 mm. This level of precision reduces material waste and minimizes rework.

According to a report by the International Journal of Advanced Manufacturing Technology, companies have reported reducing their material waste by as much as 30% due to the precision of CNC cutting.

Efficiency is another significant advantage. CNC machines can cut various shapes and sizes without needing constant human supervision. This capability allows manufacturers to operate at higher speeds.

Industry surveys show that businesses utilizing CNC systems can enhance their production rates by 50% compared to manual cutting methods. However, some operators may find it challenging to adapt fully to this technology, highlighting the need for comprehensive training.

Additionally, the customization options offered by CNC glass cutting are impressive. Companies can create unique designs tailored to client specifications. Yet, achieving this requires a clear understanding of both software and machinery. This complexity can lead to mistakes for inexperienced operators. Thus, while the benefits are significant, they come with a learning curve that cannot be overlooked.

Applications of CNC Glass Cutting in Various Industries

CNC glass cutting technology has transformed various industries. From architecture to automotive, its precision plays a vital role. According to a report by MarketsandMarkets, the CNC machine market is expected to reach $100 billion by 2026, with glass cutting applications driving significant growth.

In architecture, CNC cutting enables intricate designs. Glass panels can be shaped to fit specific loading patterns. For instance, commercial buildings often feature large glass façades. These require precision to ensure structural integrity. However, the reliance on automated systems can lead to mistakes if the initial data inputs are flawed.

The automotive industry also benefits from CNC glass cutting. Windscreens and side windows are produced with accuracy. This improves vehicle safety and aesthetics. Yet, maintaining quality control can be challenging. Any miscalculation in the cutting process may lead to wasted materials. An estimated 20% of glass used in production is often discarded due to errors. Balancing efficiency and quality remains a crucial task for manufacturers in this field.

Home

About Us

Products

UPVC PVC Window Machine

Aluminum Window Machine

Glass Cutting Machine

Glass Edging Machine

Insulating Glass Machine

Glass lifting machine

Glass Washing Machine

Glass Laminating Machine

Glass Sandblasting Machine

Glass Drilling Machine

CNC Glass Working Center

CNC Non-Metal Cutting Machine

The Other Glass Machinery

Application

Download

News

Contact Us