What is a CNC Glass Milling Machine and How Does it Work

In the realm of modern manufacturing, precision and efficiency are paramount, particularly in industries that require intricate glass components. The CNC (Computer Numerical Control) Glass Milling Machine emerges as a groundbreaking tool, designed to meet the demands of contemporary glass processing. This advanced machinery utilizes computerized controls to automate the milling process, allowing for the creation of complex shapes and designs with exceptional accuracy. By harnessing the power of automation and precision engineering, the CNC Glass Milling Machine not only streamlines production but also enhances the quality of the final products.

Understanding how a CNC Glass Milling Machine operates is essential for those involved in glass fabrication and engineering. This sophisticated machine employs cutting tools that are meticulously guided by a computer program, ensuring that each cut is executed with precision. The integration of CNC technology not only minimizes human error but also allows for the replication of designs with unwavering consistency, making it invaluable in sectors such as automotive, aerospace, and architecture. As we delve deeper into the mechanics and applications of the CNC Glass Milling Machine, we will explore its significance in revolutionizing glass manufacturing and how it continues to shape the future of this industry.

What is a CNC Glass Milling Machine?

A CNC glass milling machine is an advanced tool designed for precision machining of glass materials, utilizing computer numerical control (CNC) technology for enhanced accuracy and efficiency. This technology allows for the automated movement of the milling tool based on a programmed set of instructions, enabling complex designs and intricate patterns to be achieved with minimal human intervention. According to industry reports, the global CNC machining market is projected to reach approximately $100 billion by 2025, with a significant portion of this growth attributed to the increasing applications of CNC machinery in various sectors, including the glass industry.

The functionality of a CNC glass milling machine relies on its ability to read vector-based programs and convert them into mechanical movements. By leveraging high-speed spindle rotation and specialized milling tools, these machines can perform tasks such as shaping, engraving, and drilling with exceptional precision. Reports indicate that CNC milling machines can improve production efficiency by as much as 30% compared to traditional manual milling methods. Additionally, advances in glass processing technology, including the integration of automation and robotics, are set to further enhance the capabilities of CNC glass milling machines, making them indispensable in manufacturing processes that require precision and repeatability.

Comparison of CNC Glass Milling Machine Applications

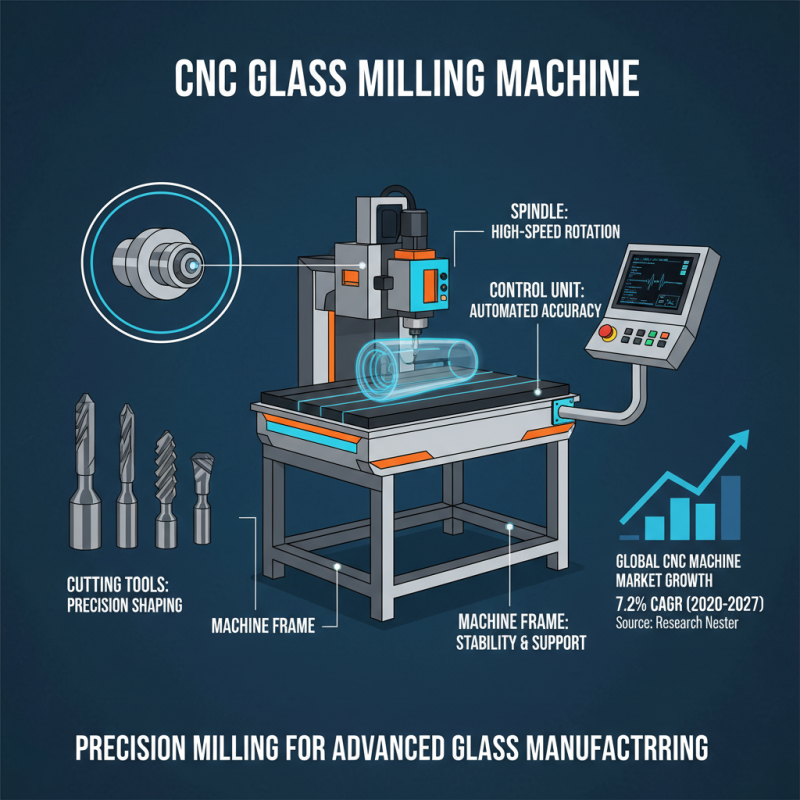

The Components of a CNC Glass Milling Machine

A CNC glass milling machine is a complex piece of equipment utilized in the manufacturing sector to precisely mill glass components. The core components of a CNC glass milling machine include the spindle, cutting tools, control unit, and the machine frame. The spindle operates to rotate the cutting tool at high speeds, enabling the efficient removal of material from the glass surface. According to a report by Research Nester, the global CNC machine market is expected to grow at a CAGR of 7.2% from 2020 to 2027, underscoring the increasing demand for such advanced capabilities in various industries including glass manufacturing.

The cutting tools used in a CNC glass milling machine are specially designed to handle glass materials, often featuring diamonds or carbide tips for improved durability and precision. In addition to the mechanical components, the control unit plays a critical role, as it interprets the design specifications and translates them into machine operations. This allows for intricate designs and cuts that meet specific customer requirements. The combination of these components allows manufacturers to achieve tolerances as tight as ±0.01 mm, which is crucial in the glass industry where precision is paramount. The efficiency and accuracy offered by CNC glass milling machines are driving their adoption, as companies seek to enhance production capabilities while minimizing waste.

How CNC Glass Milling Machines Operate

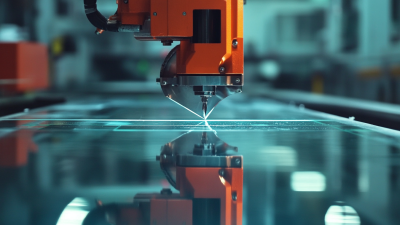

CNC glass milling machines operate by employing computer numerical control (CNC) technology to achieve precise glass fabrication. Unlike traditional milling methods that rely heavily on manual operation, CNC machines use pre-programmed software to dictate the movement of the cutting tools and workpiece. This not only enhances precision but also increases efficiency in creating complex glass shapes and designs. The process begins with a digital 3D model, which is translated into commands that instruct the machine on how to cut, shape, and finish the glass.

The operation of a CNC glass milling machine involves several key components. The cutting tool, typically made of diamond or carbide, is mounted on a spindle that rotates at high speeds, allowing it to carve through glass with ease. The workpiece is held in place on a stable bed, which may have vacuum capabilities to secure the glass during the milling process. As the machine executes the programmed instructions, the spindle moves along multiple axes—often up to five—enabling it to execute intricate patterns and detailed designs with precision. This automation not only minimizes human error but also streamlines production processes, making it ideal for both small-scale artisan projects and large-scale industrial applications.

What is a CNC Glass Milling Machine and How Does it Work

| Feature |

Description |

| Machine Type |

CNC Glass Milling Machine |

| Control System |

Computer Numerical Control (CNC) |

| Material Processed |

Glass and glass composites |

| Typical Applications |

Cutting, shaping, and engraving glass |

| Key Benefits |

High precision, repeatability, and efficiency |

| Machine Components |

Spindle, tool holder, coolant system, CNC controller |

| Operating Environment |

Usually in workshops or manufacturing facilities |

| Typical Speed Range |

10,000 to 25,000 RPM |

| Software Used |

CAD/CAM software for design and toolpath simulation |

Applications of CNC Glass Milling in Industry

CNC glass milling machines have revolutionized the

glass processing industry, providing precise and efficient ways to create intricate designs and components. One major application of CNC glass milling is in the

automotive sector, where high-quality glass components such as windshields and window panels are crucial. These machines allow for the precise shaping of glass, ensuring a

perfect fit and enhancing the overall aesthetics of vehicles.

In the architectural field, CNC glass milling machines are used to craft decorative glass elements in buildings. From complex window designs to artistic facades, the flexibility of CNC technology enables architects to push the boundaries of creativity while maintaining

accuracy. Additionally, in the electronics industry, CNC glass milling is essential for producing high-precision glass parts for devices like smartphones and tablets, where

clarity and durability are paramount.

Tips for maximizing efficiency with CNC glass milling include maintaining your machine regularly to ensure precision and longevity, and experimenting with different milling speeds and tool materials to find the optimal settings for various glass types. Additionally, investing in

high-quality cutting tools can lead to better finishes and reduced production time, ultimately elevating the quality of your products. Harnessing these tips can significantly enhance the overall performance of your CNC glass milling processes.

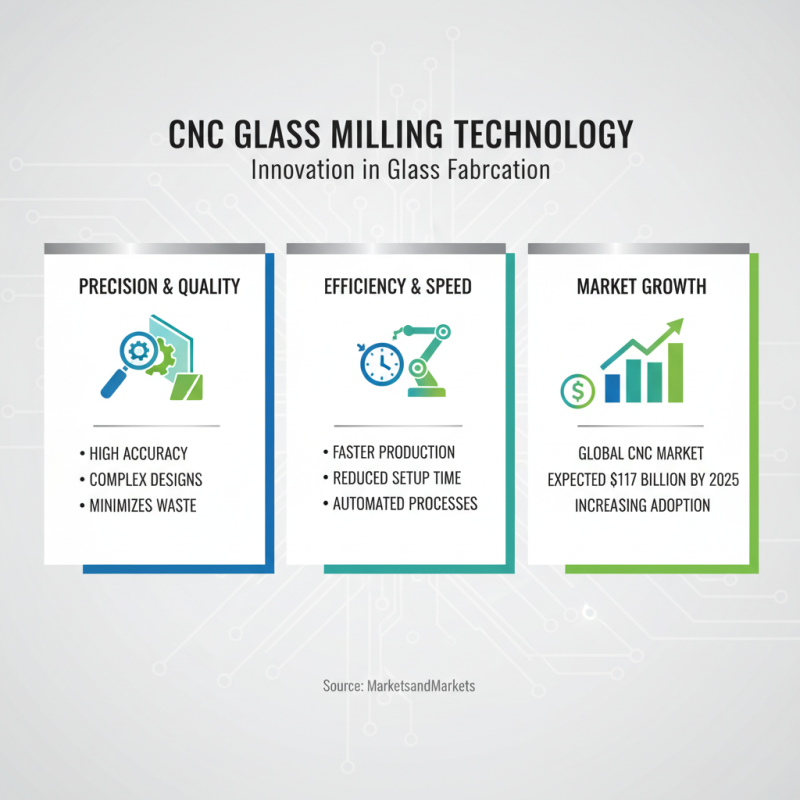

Advantages of Using CNC Glass Milling Technology

CNC glass milling technology has emerged as a pivotal innovation in the glass fabrication industry, providing numerous advantages that significantly enhance production efficiency and output quality. One of the key benefits is the precision that CNC glass milling machines offer. According to a report by MarketsandMarkets, the global CNC machine market is expected to reach $117 billion by 2025, highlighting the increasing adoption of CNC technology across various sectors, including glass manufacturing. With the ability to execute complex designs with high accuracy, CNC milling minimizes material waste and significantly reduces the time required for manual setups and adjustments.

Furthermore, CNC glass milling empowers manufacturers to achieve consistent quality in their products. By employing computer numerical control, machines can replicate designs with exact precision, alleviating the human error often associated with manual processes. A study from Frost & Sullivan indicates that automation in manufacturing can improve productivity by up to 30%, showcasing how CNC technology not only streamlines operations but also enhances resource utilization. This reliability in production yields higher customer satisfaction and drives competitive advantage in a rapidly evolving market landscape, where quality and efficiency are paramount for success.

Home

About Us

Products

UPVC PVC Window Machine

Aluminum Window Machine

Glass Cutting Machine

Glass Edging Machine

Insulating Glass Machine

Glass lifting machine

Glass Washing Machine

Glass Laminating Machine

Glass Sandblasting Machine

Glass Drilling Machine

CNC Glass Working Center

CNC Non-Metal Cutting Machine

The Other Glass Machinery

Application

Download

News

Contact Us