Revolutionizing Manufacturing: The Impact of CNC Glass Cutting Machines on Precision and Efficiency

In recent years, the manufacturing industry has witnessed a significant transformation driven by technological advancements, particularly with the advent of the CNC glass cutting machine. This cutting-edge equipment has revolutionized the way glass is processed, offering unparalleled precision and efficiency that traditional cutting methods simply cannot match. With its computer numerical control capabilities, the CNC glass cutting machine allows for intricate designs and flawless cuts, minimizing waste and maximizing production speed. As businesses strive to stay competitive in a fast-paced market, understanding how to effectively integrate and utilize CNC glass cutting machines becomes essential. This guide will explore the various advantages of these machines, provide insights into their operation, and demonstrate how they can be leveraged to enhance overall manufacturing processes, ultimately leading to increased profitability and client satisfaction.

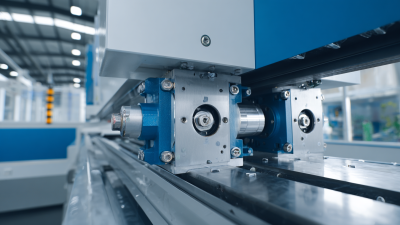

Advancements in CNC Technology for Glass Cutting

The advancements in CNC technology have transformed the glass cutting industry, enabling unprecedented levels of precision and efficiency. Modern CNC glass cutting machines utilize state-of-the-art software and hardware to automate the cutting process, significantly reducing the margin for error. These machines employ advanced algorithms that optimize cutting paths and reduce waste, allowing manufacturers to produce intricate designs with the utmost accuracy. The integration of laser and waterjet cutting techniques further enhances the capability of CNC systems, enabling them to handle different types of glass with varying thicknesses and compositions.

Moreover, CNC technology has revolutionized production speed in glass manufacturing. Unlike traditional methods, which rely heavily on manual labor and can be slow and inconsistent, CNC machines can operate continuously with minimal downtime. This efficiency not only accelerates output but also allows for customization and flexibility in production. As a result, businesses can respond quickly to market demands and provide tailored solutions to their clients. The ongoing advancements in CNC technology promise to push the boundaries of what is possible in glass cutting, driving innovation and competitiveness in the manufacturing sector.

Enhancing Precision in Glass Manufacturing with CNC Machines

CNC (Computer Numerical Control) glass cutting machines are transforming the glass manufacturing industry by significantly enhancing precision and efficiency. According to a report by Research and Markets, the global CNC machine market is expected to grow at a CAGR of 7.4% from 2021 to 2026. This rise is largely attributed to advancements in technology, particularly in precision cutting processes. CNC machines allow manufacturers to achieve tolerances as low as ±0.01 mm, which is critical for applications involving intricate designs or high-quality glass products.

CNC (Computer Numerical Control) glass cutting machines are transforming the glass manufacturing industry by significantly enhancing precision and efficiency. According to a report by Research and Markets, the global CNC machine market is expected to grow at a CAGR of 7.4% from 2021 to 2026. This rise is largely attributed to advancements in technology, particularly in precision cutting processes. CNC machines allow manufacturers to achieve tolerances as low as ±0.01 mm, which is critical for applications involving intricate designs or high-quality glass products.

Implementing CNC technology not only improves the accuracy of cuts but also optimizes production time. A case study from the Glass Association of North America indicated that firms using CNC machines have reduced production times by up to 30%, translating to lower operational costs and increased output. This efficiency can be further enhanced by integrating software that allows for precise programming and real-time adjustments during the cutting process, minimizing waste and maximizing resource utilization.

Tips: To maximize the benefits of CNC glass cutting machines, ensure staff are well-trained in both machine operation and the accompanying software. Regular maintenance of the equipment is also essential to maintain precision levels and prolong the lifespan of the machines. Lastly, consider investing in advanced analytics to monitor production metrics, helping identify areas for improvement and boosting overall efficiency.

Efficiency Gains: Reducing Waste and Time in Glass Cutting

The advent of CNC glass cutting machines has transformed the glass manufacturing landscape, ensuring precision and boosting efficiency significantly. By automating the cutting process, these machines minimize human error and create consistently high-quality products. One of the most crucial benefits is the substantial reduction in waste. Traditional glass cutting methods often resulted in excess material and costly mistakes. CNC machines, equipped with advanced software, calculate optimal cutting patterns that maximize material usage and minimize scrap.

**Tips for Optimizing Efficiency in Glass Cutting:**

Firstly, regular maintenance of CNC machines is vital to ensure they operate at peak efficiency. A well-maintained machine leads to fewer breakdowns and a smoother production process. Secondly, investing in quality raw materials can enhance the performance of your CNC machine, as high-quality glass can minimize flaws and further reduce waste during the cutting process. Lastly, training staff on the latest software and techniques can lead to more efficient workflow, allowing your team to leverage the full potential of CNC technology.

Incorporating these practices not only boosts production speed but also fosters a more sustainable manufacturing environment. As companies prioritize efficiency, CNC glass cutting machines stand at the forefront, marking a significant step toward zero-waste manufacturing.

Efficiency Gains in CNC Glass Cutting

Applications of CNC Glass Cutting Machines in Various Industries

CNC glass cutting machines have become indispensable tools across various industries, significantly enhancing precision and efficiency in glass fabrication.

In the automotive sector, for instance, the integration of CNC technology allows for intricate designs that align perfectly with modern vehicle aesthetics, reducing material wastage by

30% compared to traditional cutting methods. Similarly, in architecture, CNC machines enable the production of customized glass panels that meet specific

dimensional and design requirements, thus supporting the trend of contemporary, transparent structures.

Beyond automotive and architecture, the home furnishings industry has also benefited from CNC glass cutting. It enables manufacturers to create intricate tabletop designs, where precision is paramount.

A

2022 market report indicated that the demand for precisely cut decorative glass products has surged by

40%, emphasizing the growing consumer preference for customized home decor solutions.

Tips: When considering CNC glass cutting for your projects, ensure that you select machines that offer not just speed, but also advanced scoring techniques to

minimize glass chipping.

Regular maintenance is crucial; keeping machines calibrated will enhance cut quality and prolong their lifespan. Emphasizing employee training

on these systems can further increase productivity and safety in the workplace.

Future Trends: Innovations in CNC Glass Cutting Technology

The advent of CNC glass cutting technology has transformed the manufacturing landscape by enhancing precision and efficiency. As we look to the future, several innovations are poised to further advance this field. One of the standout trends is the integration of artificial intelligence and machine learning into CNC systems. These technologies allow for real-time monitoring and adjustments during the cutting process, resulting in higher accuracy and less waste.

With AI-driven analytics, manufacturers can optimize cutting paths and reduce production time, ultimately leading to significant cost savings.

Another exciting trend is the development of multi-function CNC machines that can handle various materials beyond glass. By incorporating capabilities for cutting, engraving, and even polishing, these machines enhance workflow and reduce the need for multiple pieces of equipment. Additionally, advancements in laser technology are enabling more intricate designs and complex cuts that were previously unattainable. As these trends continue to evolve, they promise not only to redefine manufacturing standards but also to boost creative possibilities in the glass industry.

Home

About Us

Products

UPVC PVC Window Machine

Aluminum Window Machine

Glass Cutting Machine

Glass Edging Machine

Insulating Glass Machine

Glass lifting machine

Glass Washing Machine

Glass Laminating Machine

Glass Sandblasting Machine

Glass Drilling Machine

CNC Glass Working Center

CNC Non-Metal Cutting Machine

The Other Glass Machinery

Application

Download

News

Contact Us

CNC (Computer Numerical Control) glass cutting machines are transforming the glass manufacturing industry by significantly enhancing precision and efficiency. According to a report by Research and Markets, the global CNC machine market is expected to grow at a

CNC (Computer Numerical Control) glass cutting machines are transforming the glass manufacturing industry by significantly enhancing precision and efficiency. According to a report by Research and Markets, the global CNC machine market is expected to grow at a