How to Choose the Right Glass Polishing Machine for Your Business Needs

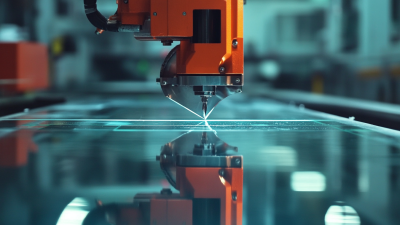

In the ever-evolving glass manufacturing and finishing industry, the demand for high-quality workmanship has never been more critical. The global glass market is projected to reach USD 181.2 billion by 2027, growing at a CAGR of 4.1%, signaling a robust need for efficient and precise finishing tools. One essential piece of equipment in this realm is the Glass Polishing Machine, which plays a pivotal role in enhancing surface quality and reducing post-production defects. As per industry reports, companies that utilize advanced glass polishing technology experience a 30% increase in operational efficiency and a significant reduction in labor costs. Choosing the right Glass Polishing Machine tailored to your specific business needs can thus not only improve product quality but also streamline production processes and bolster competitive advantage in a crowded marketplace.

In the ever-evolving glass manufacturing and finishing industry, the demand for high-quality workmanship has never been more critical. The global glass market is projected to reach USD 181.2 billion by 2027, growing at a CAGR of 4.1%, signaling a robust need for efficient and precise finishing tools. One essential piece of equipment in this realm is the Glass Polishing Machine, which plays a pivotal role in enhancing surface quality and reducing post-production defects. As per industry reports, companies that utilize advanced glass polishing technology experience a 30% increase in operational efficiency and a significant reduction in labor costs. Choosing the right Glass Polishing Machine tailored to your specific business needs can thus not only improve product quality but also streamline production processes and bolster competitive advantage in a crowded marketplace.

Understanding Different Types of Glass Polishing Machines Available in the Market

When selecting the right glass polishing machine for your business, it's essential to understand the different types available in the market. Various glass polishing machines cater to different needs, from manual and semi-automatic to fully automatic systems. Each type has its unique advantages, with automatic machines often offering higher efficiency and consistency, ideal for larger-scale operations. For businesses focusing on high-volume output, investing in a technologically advanced machine may yield a higher return on investment by reducing labor costs and increasing production speed.

Recent industry reports indicate that the market for glass polishing and processing equipment is on the rise. With the shot blasting machine market projected to expand significantly from $1.41 billion in 2025 to $2.22 billion by 2032 at a CAGR of 6.7%, there's a clear indication of growing demand for efficient surface treatment solutions. Additionally, the overall market for commercial bar supplies, which often includes glass equipment, is expected to grow substantially, indicating broadening applications for glass polishing technologies. Understanding these market trends can guide businesses in making informed choices about investing in the right equipment to meet their operational goals.

How to Choose the Right Glass Polishing Machine for Your Business Needs

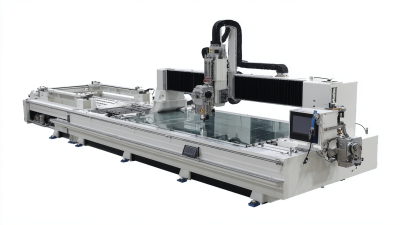

| Machine Type |

Polishing Method |

Material Compatibility |

Power Source |

Typical Use Case |

| Automatic Glass Polisher |

CNC Control |

Flat and Curved Glass |

Electric |

Large Scale Production |

| Handheld Glass Polisher |

Rotary Buffing |

Flat Glass |

Corded or Battery |

DIY and Small Jobs |

| Tabletop Glass Polisher |

Wet Polishing |

Art Glass and Mirrors |

Electric |

Precision Work |

| Vertical Glass Polisher |

Belt Polishing |

Flat Glass |

Electric |

High Volume Production |

| Glass Edge Polisher |

Diamond Grinding |

Edges of Various Glass Types |

Electric |

Edge Finishing |

Key Features to Consider When Selecting a Glass Polishing Machine

When selecting a glass polishing machine, several key features should be taken into account to ensure it meets your business needs. Firstly, consider the machine's horsepower and motor specifications, as these directly impact efficiency and the quality of polish achievable. According to industry reports, machines with a minimum of 2 HP are typically more capable of handling tougher materials, resulting in a smoother finish and better productivity.

Additionally, the size and weight of the machine can significantly affect mobility and usability in your workspace. Many businesses find that a portable option with dimensions that suit their shop layout allows for more flexible usage. Another critical feature is the presence of advanced dust and water control systems, which not only enhances the machine's lifespan but also maintains a cleaner working environment. Research shows that machines designed with effective filtration systems can reduce dust by up to 90%, which is essential for both operator health and product quality.

Finally, consider the available tooling options and the machine's compatibility with different polishing pads and techniques. This versatility not only maximizes the machine’s use for various projects but also helps in maintaining operational costs, making the right choice an investment in your business's future success.

Evaluating Your Business Needs: Size, Volume, and Type of Glass

When choosing the right glass polishing machine for your business, it's crucial to evaluate your specific needs based on the size, volume, and type of glass you handle. For businesses dealing with large sheets of glass or high volumes, investing in a robust machine that can handle continuous operation is essential. Larger machines often come equipped with advanced features that enable faster polishing speeds and superior finish quality, ensuring you meet customer demands efficiently.

On the other hand, if your focus is on small-scale operations or specialty glass products, a more compact and versatile machine might be the best choice. Machines designed for niche markets can provide tailored functionalities, allowing for precise polishing of various glass types. The key is to assess your workflow and the types of glass you polish regularly; this will help determine whether you need a heavy-duty solution or one that offers flexibility for various applications. By aligning your choice with your business needs, you set the stage for enhanced productivity and customer satisfaction.

Comparing Manual vs. Automatic Glass Polishing Machines

When it comes to glass polishing machines, choosing between manual and automatic options can significantly impact your business's efficiency and output quality. Manual glass polishing machines offer precise control and are often more affordable, making them a suitable choice for smaller operations or those just starting in the glass industry. Users can adjust the pressure and speed of polishing to suit different glass types, ensuring a high-quality finish. However, manual machines require more time and labor input, which can be a drawback for high-volume settings.

On the other hand, automatic glass polishing machines streamline the polishing process, saving time and increasing productivity. These machines can consistently deliver high-quality results with minimal operator intervention, making them ideal for larger businesses or those looking to scale up operations. While the initial investment may be higher, the efficiency and reduced labor costs can lead to greater long-term savings. Ultimately, the decision between manual and automatic glass polishing machines hinges on your business needs, budget, and production goals. Careful consideration of these factors will help you select the right equipment to meet your demands.

Glass Polishing Machine Comparison

Budgeting for Glass Polishing Equipment: Cost Analysis and ROI

When considering the acquisition of a glass polishing machine, budgeting should be at the forefront of your planning process. Understanding the full cost of the equipment goes beyond the purchase price; it includes maintenance, operational expenses, and potential downtimes. A comprehensive cost analysis is essential to evaluate whether the investment aligns with your business goals. For instance, high-quality machines might require a higher initial expenditure but can save significant costs in repairs and inefficiencies over time.

Return on investment (ROI) is another crucial factor to consider. Evaluate how the glass polishing machine will enhance your productivity and quality of output. Improved polishing can lead to increased customer satisfaction and repeat business, while effective machines can speed up production timelines. By calculating projected revenue against the total costs associated with the new equipment, you can determine if it will provide a favorable ROI. Ultimately, investing in the right glass polishing machine can lead to enhanced operational efficiency and long-term profitability for your business.

Home

About Us

Products

UPVC PVC Window Machine

Aluminum Window Machine

Glass Cutting Machine

Glass Edging Machine

Insulating Glass Machine

Glass lifting machine

Glass Washing Machine

Glass Laminating Machine

Glass Sandblasting Machine

Glass Drilling Machine

CNC Glass Working Center

CNC Non-Metal Cutting Machine

The Other Glass Machinery

Application

Download

News

Contact Us

In the ever-evolving glass manufacturing and finishing industry, the demand for

In the ever-evolving glass manufacturing and finishing industry, the demand for