Top Tips for Choosing the Right Glass Beveling Machine?

When selecting a Glass Beveling Machine, insights from industry experts can be invaluable. Renowned glass expert, John Smith, once stated, "The right machine can elevate your craftsmanship significantly." This emphasizes the importance of making informed choices.

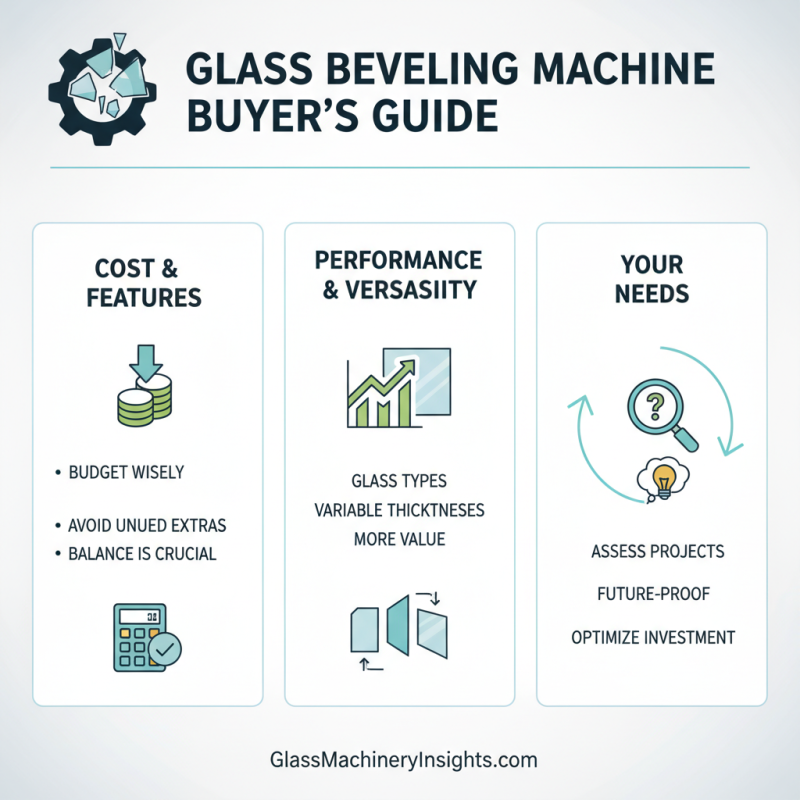

Choosing the right Glass Beveling Machine involves numerous factors. Think about production volume, machine capabilities, and ease of use. Many buyers overlook maintenance costs, which can add up. The ideal machine should not only meet current needs but also adapt to future demands.

However, it’s easy to get overwhelmed by options. Some features may seem appealing but prove unnecessary. If you focus solely on price, you might miss the long-term value of better equipment. Reflect on your specific requirements. Your choice in a Glass Beveling Machine is crucial to your overall production quality.

Understanding Glass Beveling Machines: Types and Applications

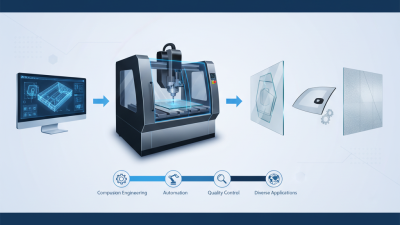

When choosing a glass beveling machine, understanding the types and applications is crucial. There are several types of beveling machines, including manual, semi-automatic, and fully automatic models. Manual machines often require skilled operators but are more affordable. Semi-automatic and fully automatic machines boost efficiency, as reported by the Glass Association, which states that automation can increase production speed by up to 50%.

Applications for glass beveling vary considerably. In the construction industry, beveled glass is popular for enhancing aesthetics. Architectural firms frequently use these machines to create custom designs. However, not all applications require the same bevel angle or quality. Some machines may struggle with thicker or larger glass pieces, which could lead to inconsistencies. According to an industry report, nearly 30% of glass defects are attributed to improper beveling processes.

Cost is another factor that influences choices. Budget constraints often limit options, leading to compromises on quality. A less expensive machine might not offer the precision needed for high-end projects. Moreover, ongoing maintenance can add hidden costs. Regular servicing is essential to keep machines efficient and avoid downtimes.

Key Features to Consider When Selecting a Beveling Machine

When selecting a glass beveling machine, certain key features can greatly impact your decision.

Power and motor capacity are crucial. A machine with a more robust motor will handle thicker glass and provide cleaner edges.

Look for adjustable speed settings. They allow greater flexibility for different glass types. A wide range of speeds helps in achieving optimal bevel angles.

Another important aspect is the machine's design. A user-friendly interface is vital. A complex setup can lead to errors. Ensure that the machine has clear, easy-to-read gauges and controls.

Additionally, consider the size and portability of the machine. A compact model may fit better in smaller shops but could limit processing larger pieces of glass.

Safety features cannot be overlooked. Look for machines that include protective coverings and emergency shut-offs.

These technologies help prevent accidents in busy work environments. If the machine requires maintenance, seek models with accessible components. This minimizes downtime and frustration.

Each of these aspects requires careful consideration and reflection. Choosing a machine shouldn't be rushed. It demands thoughtful evaluation to find the perfect fit for your needs.

Analyzing Production Speed and Efficiency Metrics in Beveling Machines

When selecting the right glass beveling machine, it’s crucial to focus on production speed and efficiency. Industry statistics reveal that machines with higher production rates can significantly enhance productivity. A study found that machines operating at 1.5 meters per minute can complete jobs faster than competitors at 1 meter per minute. This speed translates to better output over time.

Efficiency metrics are equally important. Machines are often assessed based on their energy consumption and waste rate. For example, a beveling machine that uses less energy yet maintains high output can save costs long-term. Many operations overlook this aspect, leading to unexpected expenses.

Tip: Evaluate the machine's energy ratings before making a decision. A slight increase in initial costs may result in savings later.

Additionally, consider the versatility of the beveling machine. Some machines are limited to specific glass sizes or shapes. This limitation can hinder operations in the long run. Machines that require frequent adjustments can slow down production, impacting overall profitability. Training staff on varied machine settings is essential, yet often neglected.

Tip: Analyze whether the machine can handle future production demands. Flexibility can be a game-changer in a competitive market.

Maintenance and Support Considerations for Long-term Use of Machines

Maintaining a glass beveling machine is essential for optimal performance. Regular inspections help identify wear and tear. Keep an eye on the blades; dull blades can lead to poor quality cuts. Cleaning the machine after every use prevents dust and resin buildup. This practice ensures smooth operation.

Support is equally important for long-term use. Manufacturers often provide manuals that detail maintenance procedures. However, not all operators take the time to read them. Understanding the machinery helps in troubleshooting minor issues before they escalate. Engaging with user communities can offer valuable insights and tips that manuals may overlook.

Consider establishing a routine maintenance schedule. This can help in prolonging the life of the machine. Documenting any repairs or adjustments is helpful. However, some users neglect this step, leading to repeated mistakes. Reflecting on past experiences can enhance future performance. Remember, a well-maintained machine promotes efficiency and quality.

Home

About Us

Products

UPVC PVC Window Machine

Aluminum Window Machine

Glass Cutting Machine

Glass Edging Machine

Insulating Glass Machine

Glass lifting machine

Glass Washing Machine

Glass Laminating Machine

Glass Sandblasting Machine

Glass Drilling Machine

CNC Glass Working Center

CNC Non-Metal Cutting Machine

The Other Glass Machinery

Application

Download

News

Contact Us