How to Choose the Right Glass Beveling Machine for Your Business Needs

In today's competitive landscape, selecting the right Glass Beveling Machine is crucial for businesses aiming to enhance their operational efficiency and product quality. According to a recent industry report by Grand View Research, the global glass processing market is expected to reach USD 24.3 billion by 2025, driven largely by the increasing demand for customized glass products in various sectors, including construction and interior design.

The right beveling machine not only improves the aesthetic appeal of glass but also contributes to the overall durability and safety of glass installations. Therefore, understanding the specifications, capabilities, and long-term benefits of different glass beveling machines is essential for decision-makers looking to invest in equipment that meets their specific business needs and keeps pace with industry trends.

The right beveling machine not only improves the aesthetic appeal of glass but also contributes to the overall durability and safety of glass installations. Therefore, understanding the specifications, capabilities, and long-term benefits of different glass beveling machines is essential for decision-makers looking to invest in equipment that meets their specific business needs and keeps pace with industry trends.

Understanding Your Glass Beveling Requirements for Optimal Choice

When selecting the right glass beveling machine, it is crucial to understand your specific glass beveling requirements. Various factors come into play, including the thickness of the glass, the desired bevel angle, and the production volume. According to industry reports, demand for customized beveling solutions has increased by over 25% in the past three years, highlighting the need for machines that can handle a diverse range of glass types and bevel specifications.

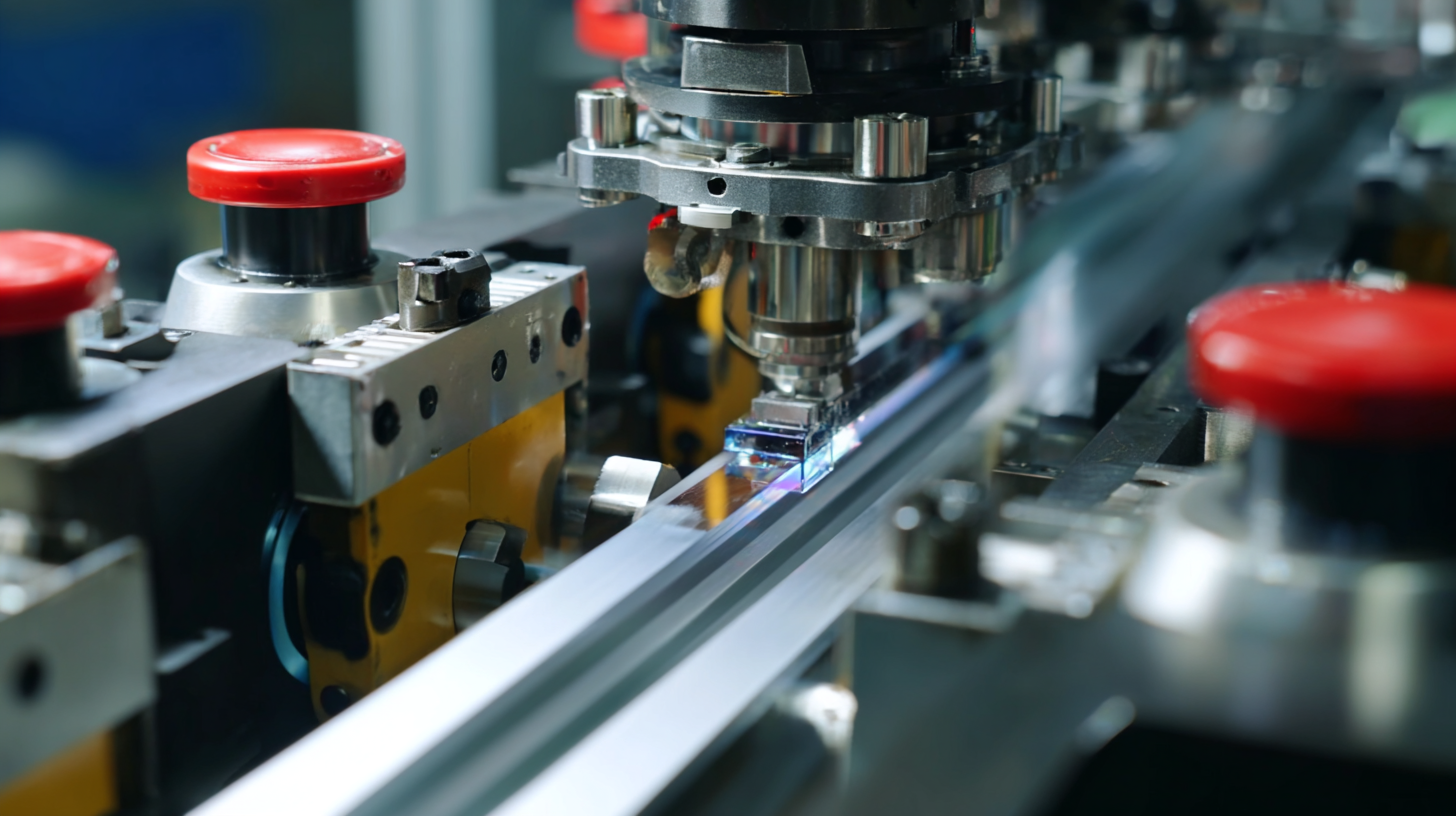

Manufacturers are now focusing on delivering machines that not only provide precision but are also versatile enough for different applications. For instance, nonthermal beveling technologies allow for a variety of operations without causing heat-affected zones (HAZ), which can negatively impact the integrity of the glass. Furthermore, trends indicate a growing preference for automated systems that enhance productivity while ensuring consistent quality in bevel edges. By aligning your machine selection with these evolving industry standards, you can significantly improve your glass fabrication processes and meet the varying demands of your customers.

Evaluating Different Types of Glass Beveling Machines Available

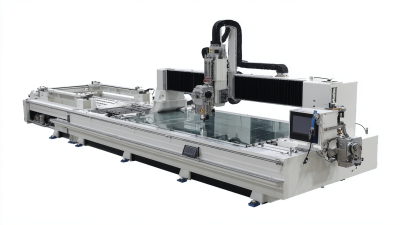

When evaluating different types of glass beveling machines for your business, it's essential to consider the specific applications and the materials you'll be working with. Glass beveling machines can vary significantly in design, capability, and performance, making it crucial to choose one that aligns with your operational needs. For example, high-end machines equipped with programmable controls and multiple spindle configurations may be more suited for large-scale manufacturers who require precision and efficiency when processing architectural tempered glass.

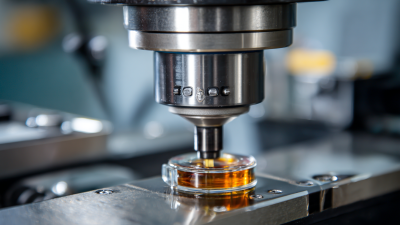

Recent research highlights the importance of edge stress evaluation in tempered glass, emphasizing how the choice of machine can impact the overall quality and safety of your products. According to industry reports, employing advanced photoelastic measurement techniques can significantly improve the assessment of edge stresses, which are critical in applications such as architectural installations. For businesses processing thicker glass, investing in a robust beveling machine that can handle larger thicknesses while minimizing edge stresses will ensure compliance with safety standards and enhance product longevity. Notably, the integration of sophisticated software that supports fitting functions for edge assessment could further streamline production processes and improve quality control measures.

Key Features to Look for in a Glass Beveling Machine

When selecting a glass beveling machine, understanding the key features is crucial to suit your business needs. First and foremost, the machine's production capacity plays a vital role. According to the Glass Association of North America, the demand for glass products is projected to grow by 4.2% annually through 2025. A high-capacity beveling machine can significantly enhance operational efficiency and meet increasing demands.

Another critical feature is the precision and range of bevel options. Machines that offer adjustable bevel angles and precise control mechanisms can enhance product versatility, catering to a broader range of client specifications. Recent industry reports indicate that businesses using advanced CNC beveling technologies have seen productivity increases of up to 30%. Moreover, the ease of maintenance and operation should not be overlooked, as machines with user-friendly interfaces and accessible components minimize downtime, further improving productivity and reducing labor costs. Careful consideration of these features will ensure the chosen machine aligns with production goals and enhances overall profitability.

How to Choose the Right Glass Beveling Machine for Your Business Needs - Key Features to Look for in a Glass Beveling Machine

| Feature |

Description |

Importance |

Average Price Range |

| Motor Power |

Power of the machine's motor, affects speed and efficiency. |

High |

$3,000 - $15,000 |

| Bevel Angle Range |

The range of angles that can be beveled, usually between 0 and 45 degrees. |

Medium |

$1,500 - $5,000 |

| Glass Thickness Capacity |

Max and min thickness of glass that can be processed. |

High |

$2,000 - $10,000 |

| Automation Features |

Include features like CNC programming for precise cuts. |

Very High |

$10,000 - $50,000 |

| Safety Features |

Includes guards, emergency stop buttons, and safety certifications. |

High |

$500 - $3,000 |

| Ease of Use |

How intuitive the controls and setup are for operators. |

Medium |

$1,000 - $4,000 |

Budget Considerations: Investment vs. Long-term Benefits

When selecting a glass beveling machine, it’s crucial to weigh your budget against the long-term benefits of your investment. According to a report by the Glass Association, businesses that invest in high-quality beveling machines can see up to a 30% increase in production efficiency. While a lower initial cost might be tempting, consider that cheaper machines often come with higher operational costs and frequent maintenance needs, which can lead to decreased productivity over time.

Tip: Evaluate your projected workload and the specific features you need in a machine. If your operations involve high volumes or complex beveling, investing in a more expensive, robust model could yield significant cost savings in the long run.

Moreover, consider the return on investment (ROI). A study published by the Manufacturing Institute indicates that businesses that invest in advanced machinery realize a return of up to 150% over five years, thanks to reduced labor costs and improved product quality. Choosing the right beveling machine is not merely about upfront costs; it’s about aligning your purchasing decision with your growth strategy and long-term operational goals.

Tip: Research different manufacturers and their warranties or service agreements, as these can impact your long-term costs and productivity substantially.

Assessing Support and Maintenance Options for Your Equipment

When selecting a glass beveling machine, it is crucial to assess not only its features but also the

support and maintenance options available. Reliable after-sales service

can greatly influence the longevity and efficiency of your equipment. Look for manufacturers that provide

comprehensive training for your team and readily available customer support. Choosing a supplier with a

solid reputation in customer service can ensure that any issues you encounter will be promptly addressed,

reducing downtime.

Tips: Before finalizing your purchase, inquire about the warranty and the availability of replacement

parts. This can save you time and money in the long run. Additionally, consider whether the manufacturer

offers maintenance contracts, which can provide you with peace of mind that

your machine will be regularly serviced by professionals.

Furthermore, evaluating the support network of the machine is vital.

A local service provider can be an asset in minimizing wait times for repairs

and maintenance. Investigate if the supplier has authorized service centers nearby and their expertise in

handling specific models. By ensuring robust support and maintenance options, you can maximize the

efficiency and productivity of your glass beveling operation.

Home

About Us

Products

UPVC PVC Window Machine

Aluminum Window Machine

Glass Cutting Machine

Glass Edging Machine

Insulating Glass Machine

Glass lifting machine

Glass Washing Machine

Glass Laminating Machine

Glass Sandblasting Machine

Glass Drilling Machine

CNC Glass Working Center

CNC Non-Metal Cutting Machine

The Other Glass Machinery

Application

Download

News

Contact Us

The right beveling machine not only improves the aesthetic appeal of glass but also contributes to the overall durability and safety of glass installations. Therefore, understanding the specifications, capabilities, and long-term benefits of different glass beveling machines is essential for decision-makers looking to invest in equipment that meets their specific business needs and keeps pace with industry trends.

The right beveling machine not only improves the aesthetic appeal of glass but also contributes to the overall durability and safety of glass installations. Therefore, understanding the specifications, capabilities, and long-term benefits of different glass beveling machines is essential for decision-makers looking to invest in equipment that meets their specific business needs and keeps pace with industry trends.