How to Choose the Best Glass Loading Table for Your Needs in 2025

In the fast-evolving world of glass manufacturing and processing, selecting the right equipment is crucial for optimizing productivity and ensuring safety. One of the essential tools in this industry is the Glass Loading Table, which greatly enhances the efficiency of handling large sheets of glass. As we approach 2025, a variety of options are available, each designed with unique features to cater to different operational needs. This introductory guide will help manufacturers navigate the complexities of choosing the best Glass Loading Table, considering factors such as size, weight capacity, and mobility.

With technological advancements and growing industry standards, modern Glass Loading Tables have evolved significantly. They now boast features that not only improve efficiency but also enhance the safety of workers handling heavy and fragile materials. Understanding these developments will empower businesses to make informed decisions that align with their specific requirements. Whether you are operating a large-scale factory or a smaller workshop, knowing how to identify the ideal Glass Loading Table can streamline your workflow and minimize risks associated with glass handling.

Understanding Glass Loading Tables: Types and Functions

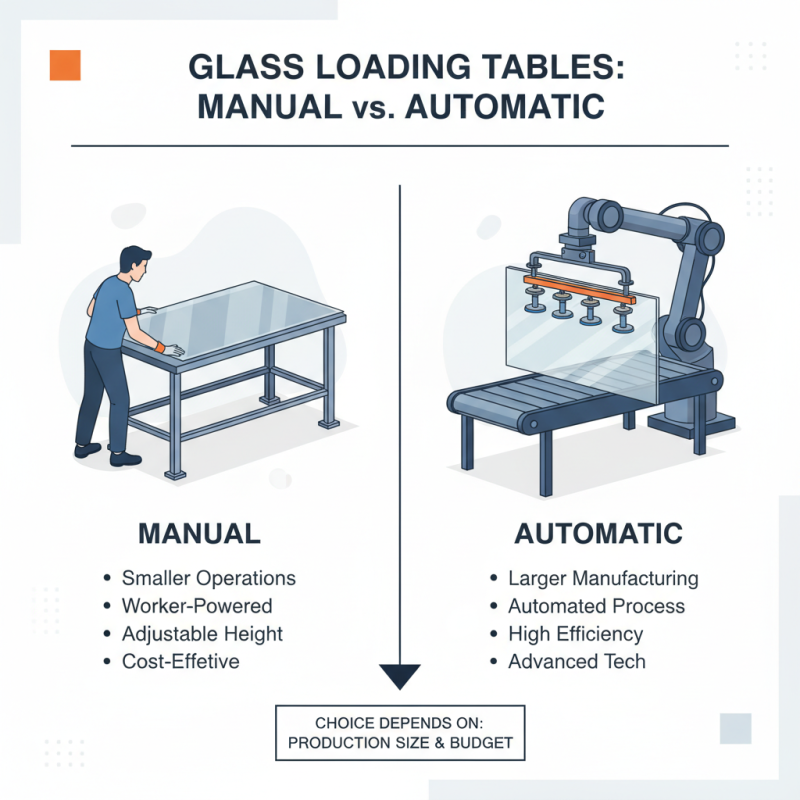

When selecting a glass loading table, it's essential to understand the different types and their functions to ensure that you choose the best one for your specific needs. Glass loading tables are primarily classified into manual and automatic varieties. Manual tables are designed for smaller operations, where workers can easily handle and position glass sheets manually. They typically feature adjustable heights and simple mechanisms for supporting various glass sizes. On the other hand, automatic glass loading tables incorporate advanced technology to streamline the loading process, significantly enhancing efficiency for larger manufacturing setups.

In addition to the basic types, glass loading tables can come with various features tailored to specific functions. For instance, some tables include vacuum systems that securely hold glass sheets in place, minimizing the risk of damage during transportation. Others might have built-in conveyors or rollers to facilitate the movement of glass within a production line. Understanding these functionalities can aid in selecting a table that not only fits your current operational requirements but also accommodates future growth, ensuring that it serves your business effectively in the years to come.

Key Features to Consider When Choosing a Glass Loading Table

When selecting the best glass loading table for your needs in 2025, it’s crucial to focus on several key features that will enhance your operational efficiency and safety. According to the industry report by the Glass Manufacturing Industry Council, the demand for ergonomic and flexible loading solutions has surged by 25% over the last three years. Buyers should prioritize tables that offer adjustable heights and customizable configurations to accommodate various glass dimensions and processing techniques. This adaptability not only improves workflow but also minimizes the risk of worker injuries by reducing strain during loading and unloading tasks.

In addition to ergonomics, another critical aspect to consider is the construction and materials used in the loading table design. As per a recent survey conducted by the International Glass Association, businesses have reported a 30% increase in durability and maintenance efficiency when using advanced composite materials over traditional steel options. A loading table made with high-strength, lightweight materials not only withstands the rigors of heavy glass handling but also enhances maneuverability within the workspace. Additionally, features such as integrated safety stop mechanisms and anti-slip surfaces can further safeguard operators in fast-paced environments, ensuring compliance with the evolving industry safety standards.

How to Choose the Best Glass Loading Table for Your Needs in 2025 - Key Features to Consider When Choosing a Glass Loading Table

| Feature |

Description |

Importance |

Recommended Value |

| Load Capacity |

Maximum weight the table can support. |

High |

Up to 2000 lbs |

| Table Size |

Dimensions of the loading area. |

Medium |

10 ft x 5 ft |

| Material Quality |

Type of materials used in construction. |

High |

Steel and tempered glass |

| Adjustability |

Ability to adjust height or tilt. |

Medium |

Yes, adjustable 28" to 42" |

| Safety Features |

Includes safety mechanisms like guards and brakes. |

High |

Yes, with anti-slip surfaces |

Industry Standards: Load Capacity and Weight Distribution in 2025

When selecting a glass loading table, understanding the industry's standards for load capacity and weight distribution in 2025 is crucial. The load capacity refers to the maximum weight the table can handle without compromising its structural integrity. It’s vital to assess the types of materials you will be handling and choose a table that can safely support them. Overloading can lead to accidents and equipment failure, so ensure that the chosen table exceeds your maximum expected load.

Weight distribution is equally important in ensuring a safe and efficient working environment. An uneven distribution of weight can lead to instability and may cause the glass to shift or break during handling. When evaluating a glass loading table, check for features that allow for even weight distribution, such as reinforced frameworks or adjustable supports.

Tips: When selecting a glass loading table, prioritize tables that have clear specifications detailing their load capacities. Additionally, consider tables with adjustable height features to better accommodate varying glass sizes, further enhancing weight distribution. Always factor in your workspace's layout, as a well-placed table can significantly improve both safety and efficiency.

Analyzing Ergonomics and Safety Features in Glass Loading Tables

When selecting a glass loading table, ergonomics and safety features are paramount considerations. Ergonomically designed tables are essential for minimizing strain on workers during the loading process.

Features such as adjustable height settings and user-friendly controls can greatly enhance comfort and efficiency. It is important to choose a table that allows operators to maintain a neutral posture, reducing the risk of musculoskeletal disorders. Additionally, surfaces that are easy to reach and manipulate can significantly improve workflow, ensuring that tasks are completed with both speed and precision.

Safety features are equally critical, given the inherent risks associated with handling glass. A good glass loading table should include features such as anti-slip surfaces, safety guards, and reinforced edges to prevent accidents. Furthermore, integrated safety sensors can alert operators to potential hazards, such as obstacles or improper positioning, thus preventing injuries. Tables equipped with proper weight distribution mechanisms can also mitigate the risk of tipping or collapsing, providing a stable and secure working environment. Prioritizing ergonomics and safety in your choice of glass loading table will not only enhance productivity but also foster a safer workspace for all employees.

Comparing Costs: Budgeting for a Glass Loading Table Investment

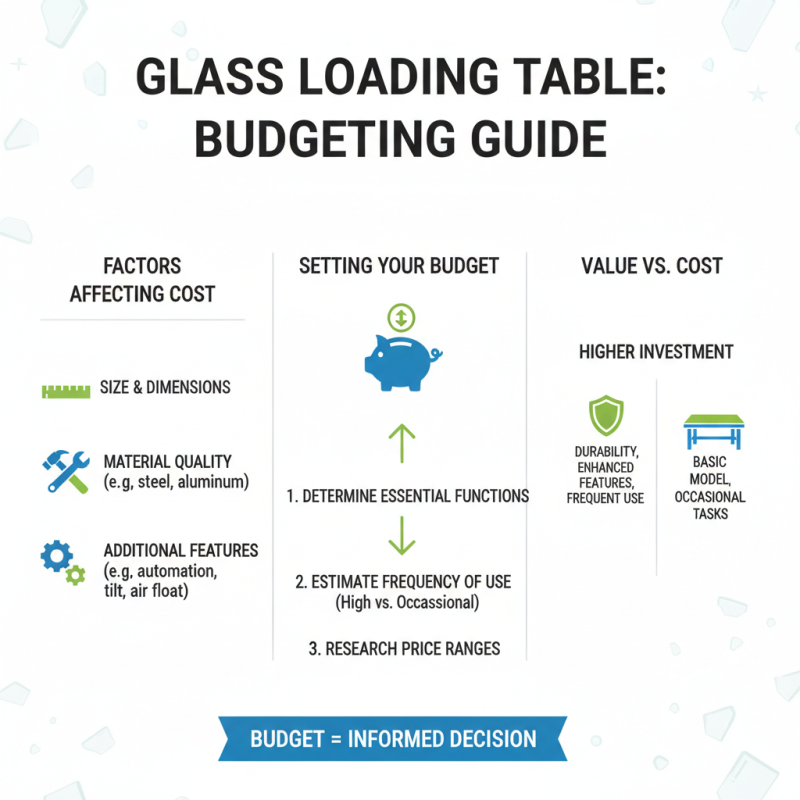

When selecting a glass loading table, budgeting is a crucial factor that can significantly influence your decision. The cost of these tables varies widely based on factors such as size, material quality, and additional features. Understanding your budget allows you to narrow down your options effectively. Initially, consider the essential functions you require from the table, as this will help you assess which specifications justify a higher investment. For example, a table designed for high-frequency use may warrant a greater expenditure due to its durability and enhanced features, while a basic model may suffice for occasional tasks.

It's also important to factor in long-term costs beyond the initial purchase price. This includes maintenance, potential repairs, and the efficiency gained through investing in a high-quality product. Cheaper tables might save money upfront but could lead to higher repair costs or replacements down the line. By analyzing the total cost of ownership over the lifespan of the glass loading table, you can make a more informed decision that aligns with both your immediate financial constraints and your long-term operational goals.

Home

About Us

Products

UPVC PVC Window Machine

Aluminum Window Machine

Glass Cutting Machine

Glass Edging Machine

Insulating Glass Machine

Glass lifting machine

Glass Washing Machine

Glass Laminating Machine

Glass Sandblasting Machine

Glass Drilling Machine

CNC Glass Working Center

CNC Non-Metal Cutting Machine

The Other Glass Machinery

Application

Download

News

Contact Us