How to Choose the Best Glass Cutting Table for Your Needs?

Choosing the right Glass Cutting Table is crucial for both professionals and DIY enthusiasts. John Stevens, a renowned glassworking expert, once said, “A proper cutting table can elevate your project from average to extraordinary.” This statement reflects the importance of selecting the best equipment for your specific needs.

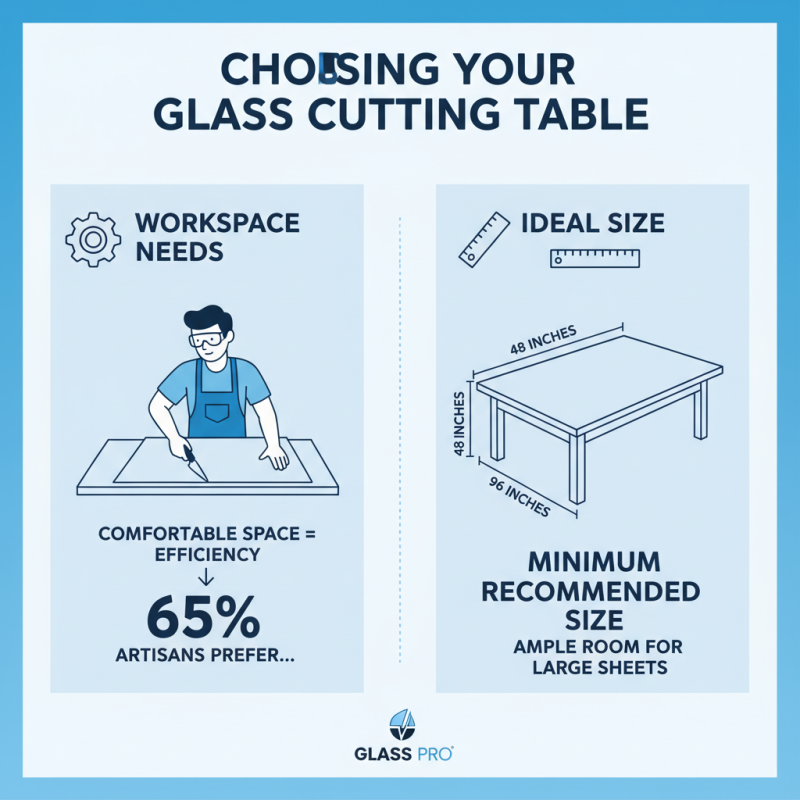

When evaluating a Glass Cutting Table, consider the size and surface material. A sturdy, flat surface is essential for precise cuts. Look for tables with built-in measurement tools and guides. These features can enhance your cutting experience and improve accuracy. However, many overlook the importance of stability. An unstable table can lead to mistakes and wasted materials.

Additionally, think about your workspace. Is there enough room for your table? Many people underestimate the space required to work efficiently. This oversight can lead to frustration and hinder creativity. Also, reflect on your cutting frequency—if you only cut glass occasionally, investing in a high-end table may not be necessary. Make sure to weigh your options carefully to find the best fit.

Understanding the Different Types of Glass Cutting Tables Available

When choosing a glass cutting table, understanding the various types is crucial. There are different styles tailored for specific needs. For example, manual cutting tables are commonly used for DIY projects. These tables are simpler and often more affordable. However, they may not provide the precision needed for professional work.

On the other hand, automated glass cutting tables are equipped with advanced technology. They use CNC machines to ensure accuracy and efficiency. Industry reports suggest that automated tables offer cutting precision of up to 0.1 mm, reducing waste significantly. This technology is pushing the boundaries of glass cutting, making it an essential investment for businesses.

Additionally, there are portable options available. These are ideal for contractors who need flexibility on-site. Yet, they may sacrifice some stability compared to larger models. Selecting the right table involves weighing these pros and cons. Many users report that the right choice can lead to substantial productivity gains, but missteps often lead to frustration and wasted materials.

How to Choose the Best Glass Cutting Table for Your Needs?

| Type of Glass Cutting Table |

Ideal Use Case |

Size (inches) |

Price Range ($) |

Portability |

| Standard Cutting Table |

General glass cutting tasks |

48 x 30 |

150 - 300 |

Stationary |

| Portable Glass Cutting Table |

On-site glass cutting |

36 x 24 |

100 - 200 |

Portable |

| Automatic Glass Cutting Table |

High volume production |

Custom sizes |

5000 - 15000 |

Stationary |

| Table with Built-in Vacuum |

Precise cutting and handling |

60 x 36 |

300 - 600 |

Stationary |

Key Features to Look for in a Quality Glass Cutting Table

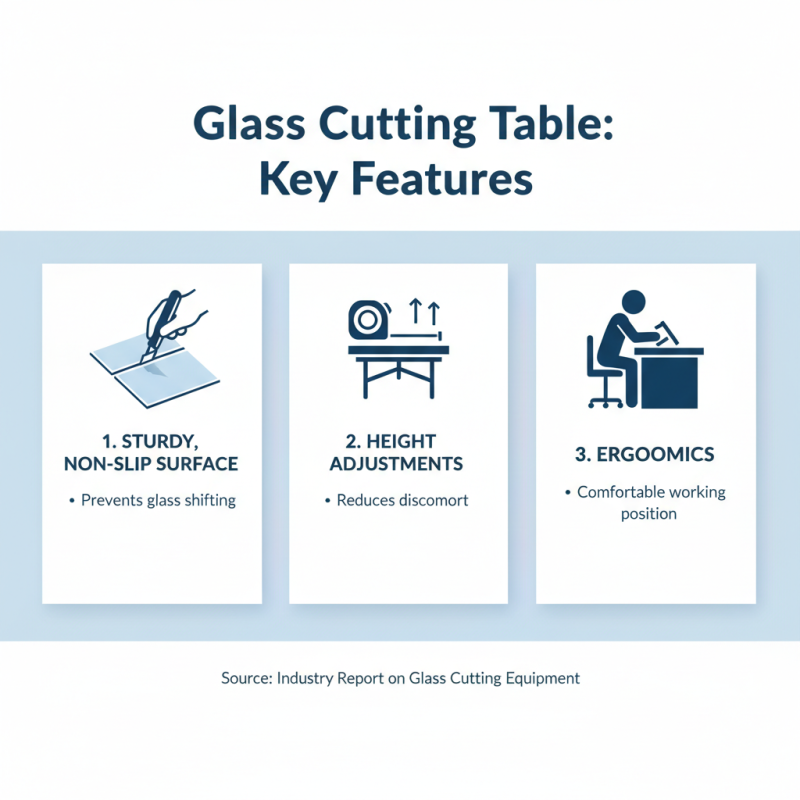

When selecting a glass cutting table, several key features make a significant difference. A sturdy, non-slip surface is essential. This prevents glass from shifting during cutting. A quality table should also have proper height adjustments. Many users report discomfort after long hours of work due to inadequate height options. Ergonomics cannot be overlooked; it's crucial to ensure a comfortable working position.

Material quality is another vital aspect. Tables made from durable materials can withstand heavy usage. According to industry data, professionals prefer tables with a strong aluminum or steel frame. These materials offer stability and longevity. Additionally, look for a table equipped with a scoring system that allows cleaner cuts. This feature can enhance precision and reduce waste.

Storage features are often undervalued. Sufficient space for tools and glass leads to better workflow. A clutter-free environment promotes efficiency. However, not every table provides adequate storage solutions. Users might feel overwhelmed by scattered tools. Therefore, reflect on these elements carefully to choose a table that fits your cutting needs closely.

Assessing Your Budget: What to Expect in Different Price Ranges

When selecting a glass cutting table, your budget plays a crucial role. On average, a basic table with essential features starts around $200. These models often lack advanced capabilities. They can serve beginners but might disappoint seasoned professionals. Investing more can lead to superior quality and functionality, often above $500.

In mid-range options, priced between $300 and $600, you can find features like adjustable heights and additional support mechanisms. Reports indicate that about 35% of users in this range experience fewer issues with cutting precision. This investment can lead to greater efficiency, so consider your long-term needs. However, imperfections may remain in these mid-tier models, leading to frustration over time.

High-end tables start at $700 and can exceed $2000. Users in this category report improved durability and features tailored for professionals. According to industry data, 80% of these users express satisfaction with their investment. Yet, some may still find them bulky or difficult to maneuver. It's essential to weigh these factors carefully before making a decision.

Maintenance and Care Tips for Prolonging the Life of Your Cutting Table

Proper maintenance of your glass cutting table is essential for longevity. A study by the Glass Cutting Industry Association reveals that regular upkeep can extend the lifespan of your table by up to 40%. Keeping the surface clean and free from debris is crucial. Dust and particles can scratch or damage the surface over time. Use a soft cloth with a gentle cleaning solution, avoiding harsh chemicals.

Additionally, ensure your table is stored in a climate-controlled environment. Extreme temperatures can affect the glass and the overall structure. A consistent temperature between 60°F and 80°F is ideal. It’s also vital to routinely check for any signs of wear or damage. Small cracks can become larger over time, leading to costly replacements.

Consider using protective mats during cutting. These mats can absorb some shocks and protect the table's surface. Yet, some users forget to replace mats as they wear out. This oversight can lead to increased risks. Remember, even small, unnoticed issues can escalate. Regular inspections can save you from more significant problems later on. Make maintenance a habit, and your cutting table will serve you well for years.

Home

About Us

Products

UPVC PVC Window Machine

Aluminum Window Machine

Glass Cutting Machine

Glass Edging Machine

Insulating Glass Machine

Glass lifting machine

Glass Washing Machine

Glass Laminating Machine

Glass Sandblasting Machine

Glass Drilling Machine

CNC Glass Working Center

CNC Non-Metal Cutting Machine

The Other Glass Machinery

Application

Download

News

Contact Us