How to Choose the Best Glass Beveling Machine for Your Needs?

Choosing the right Glass Beveling Machine can feel overwhelming. Many factors come into play. You need to understand your specific needs and preferences.

What are you planning to use the machine for? Consider the type of glass you will work with. Different machines suit different purposes. Look into the machine's specifications closely. Pay attention to its speed, size, and functionality.

Remember, not every machine will be perfect for your tasks. A machine that works well for someone else might not fit your requirements. Reflect on your production volume, the level of precision needed, and your budget. Talk to professionals in the field, and don't be afraid to ask for advice.

Understanding Different Types of Glass Beveling Machines in the Market

When choosing a glass beveling machine, understanding the types available is crucial. There are primarily two categories: manual and automatic machines. Manual machines require skilled operators to achieve precise bevels, making them ideal for small-scale operations. However, they can be labor-intensive and might lack consistency.

On the other hand, automatic machines speed up the beveling process significantly. They cater to larger production needs and often provide more uniform results. A report from the Glass Association noted that around 65% of manufacturers prefer automatic machines for efficiency. Still, these machines come with higher initial costs and maintenance challenges. Operators need training to handle complex features.

Furthermore, some machines offer specific capabilities, such as varying bevel angles. This versatility is valuable for projects requiring different bevel styles. However, not all machines can adapt. As indicated by the International Glass Industry report, 30% of glass professionals expressed concerns over the adaptability of their equipment. Evaluating these factors is essential to finding the right fit for your needs.

How to Choose the Best Glass Beveling Machine for Your Needs?

| Type of Glass Beveling Machine |

Suitable Glass Thickness |

Beveling Angle Range |

Production Speed |

Power Consumption |

Price Range (USD) |

| Manual Glass Beveling Machine |

3 - 15 mm |

20° - 45° |

5 - 10 m/min |

1 kW |

500 - 1500 |

| Semi-Automatic Glass Beveling Machine |

4 - 20 mm |

10° - 50° |

15 - 25 m/min |

2 kW |

1500 - 3000 |

| Fully Automatic Glass Beveling Machine |

5 - 25 mm |

15° - 60° |

20 - 40 m/min |

5 kW |

3000 - 7000 |

| CNC Glass Beveling Machine |

3 - 30 mm |

5° - 90° |

25 - 55 m/min |

8 kW |

7000 - 15000 |

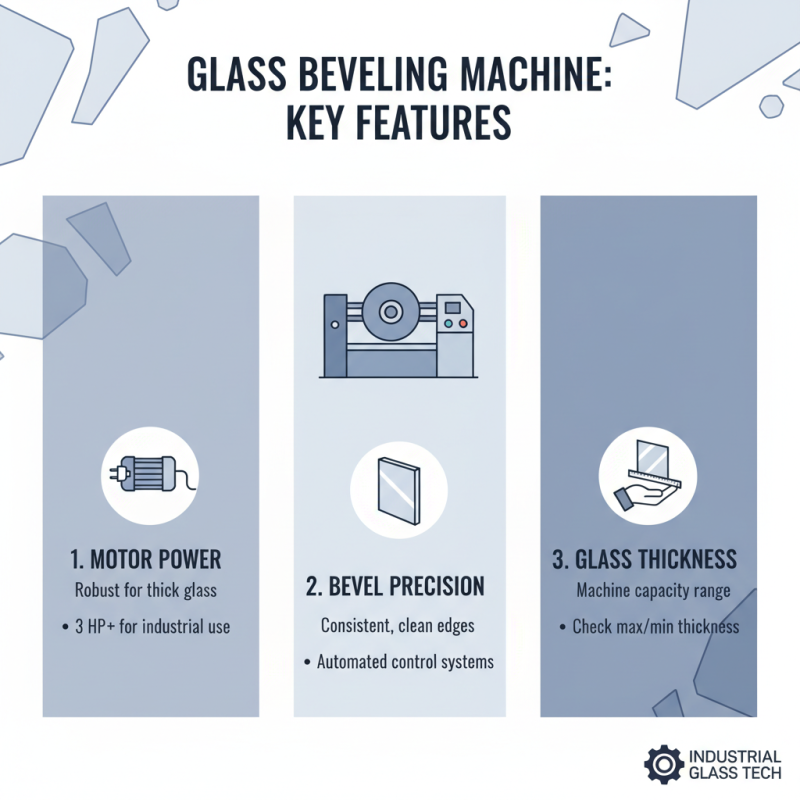

Key Features to Consider When Selecting a Glass Beveling Machine

Choosing the right glass beveling machine involves understanding several key features. First, consider the machine's motor power. A robust motor can handle thicker glass and deliver precise bevels. Reports indicate that machines with at least a 3 HP motor are optimal for most industrial needs.

Next, examine the beveling angle options. Many machines offer angles ranging from 0 to 45 degrees. Flexibility in angle adjustments can enhance creativity in designs. Industry surveys show that 65% of fabricators prefer machines that allow for varied angle settings.

Another critical feature is the ease of use. Complex interfaces often lead to errors. Simple controls, ideally with digital displays, ensure accuracy. Additionally, look for machines with a reliable dust collection system. Effective dust management keeps the workspace clean and boosts safety. Data suggest that up to 30% of operators experience issues due to poor dust removal.

Lastly, after-sales service and support can impact long-term satisfaction. While many manufacturers claim to offer excellent service, user reviews frequently tell a different story. Understanding what you truly need can prevent costly mistakes down the line.

Evaluating Production Capacity and Efficiency in Beveling Machines

When selecting a glass beveling machine, evaluating production capacity is crucial. This metric indicates how much glass can be processed within a specific time frame. A higher production capacity often translates to higher efficiency. However, it’s essential to consider the type of glass you work with. Different glass thicknesses and sizes can affect the machine’s performance. Not all high-capacity machines can handle every type of glass.

Efficiency in beveling machines is determined by their speed and quality of output. Faster machines are desirable, but speed shouldn’t compromise the quality of the beveling. A well-rounded machine should create smooth edges without chips or cracks. That said, sometimes machines may not meet expected efficiency levels due to wear and tear or improper maintenance. This can lead to slower production times and increased costs.

Incorporating advanced technology can enhance both capacity and efficiency. Automatic feed systems and programmable controls can streamline operations. However, it’s important to reflect on the learning curve associated with new technology. Operators may need training to use advanced features effectively. Careful consideration of these factors will lead to better decision-making in choosing the right beveling machine.

Cost Analysis: Budgeting for a Glass Beveling Machine Purchase

When budgeting for a glass beveling machine, it’s essential to assess your needs carefully. The cost can vary significantly based on features and capabilities. Basic models often start at a lower price, while advanced machines can quickly escalate in cost. Determine what you truly need versus what is simply nice to have.

Consider the long-term investment in quality. Cheaper machines may save money initially but could fail sooner. Think about maintenance costs and unexpected repairs. Are you prepared for those expenses? Analyze operating costs as well, such as electricity and consumables. Sometimes a higher upfront cost leads to lower operating expenses over time.

Don't overlook the space required for installation. Larger machines can take up significant floor space. Will your workshop accommodate this? Assess your layout before making a purchase. Reflect on the learning curve as well. Newer machines may come with complex controls that require training. Lastly, consider resale value. Will it hold up over time? Your choices today will influence your business tomorrow.

Maintenance and Support: Essential Post-Purchase Considerations

When selecting a glass beveling machine, post-purchase support and maintenance are crucial. Regular maintenance prolongs the life of the machine. Without proper care, issues may arise that disrupt production. Cleaning components and lubricating moving parts are essential tasks. However, these tasks can be overlooked if not prioritized.

Support options are just as important. Having access to knowledgeable technical support can alleviate stressful situations. If a problem occurs, quick resolutions can prevent downtime. Manuals and online resources should be easy to access. Training sessions for your team can also enhance the machine's effectiveness. Employees need to feel confident operating it.

Consideration of warranties is vital. A good warranty can provide peace of mind. However, it may also require careful scrutiny. Some warranties have limitations or hidden clauses. Knowing exactly what is covered helps avoid future frustrations. The choice of a machine shouldn’t focus solely on features. Consider maintenance and support as part of your long-term strategy.

Glass Beveling Machine Features Comparison

This chart compares key features of different glass beveling machines, including speed, power, maximum thickness and width capabilities, as well as price. When choosing a beveling machine, consider these essential features to meet your specific production needs.

Home

About Us

Products

UPVC PVC Window Machine

Aluminum Window Machine

Glass Cutting Machine

Glass Edging Machine

Insulating Glass Machine

Glass lifting machine

Glass Washing Machine

Glass Laminating Machine

Glass Sandblasting Machine

Glass Drilling Machine

CNC Glass Working Center

CNC Non-Metal Cutting Machine

The Other Glass Machinery

Application

Download

News

Contact Us