How to Choose the Best Glass Shape Beveling Machine?

Choosing the right Glass Shape Beveling Machine is crucial for your business. The machine's quality affects production efficiency and the final product's appearance. A good beveling machine creates smooth edges and enhances the glass's aesthetic value.

When selecting a machine, consider various factors. Think about the types of glass you work with and the bevel angles you need. Also, evaluate the machine's speed and accuracy. Some machines may not meet all your expectations, leading to frustration. You may find yourself wondering if you made the right choice.

It's also essential to consider your budget. High-end machines offer advanced features, but they can be costly. A lower-priced model might lack some capabilities you desire. It's a balancing act between performance and cost. This decision can impact your workflow and profitability. Conduct thorough research before making a commitment to any Glass Shape Beveling Machine.

Understanding Glass Shape Beveling Machines

Choosing the right glass shape beveling machine requires understanding the essential features. Glass shape beveling machines come in various configurations. The market is influenced by demands for precision and speed. According to industry reports, the global glass processing market is expected to reach $14 billion by 2025. This growth highlights the importance of selecting efficient machines.

Machine performance depends on the type of beveling. Conventional machines might lack the advanced features found in newer models. Problems can arise from improper setup. For example, a misaligned glass piece can lead to defects. A report from the Glass Association notes that nearly 30% of glass processing defects stem from machinery errors.

Understanding cutting speeds is crucial. Machines operate best at specific speeds for different glass thicknesses. Too fast, and risks of chipping increase. Too slow, and productivity drops. This balance is essential for quality output. Operators often find that inadequate maintenance contributes to inefficiency. Regular checks can mitigate this issue. Quality craftsmanship demands constant reflection and improvement.

Key Features to Consider When Selecting a Beveling Machine

When selecting the best glass shape beveling machine, it is crucial to focus on key features. The power of the motor should be a priority. A machine with a robust motor ensures smooth operation. Look for a motor range between 2 to 5 horsepower for effective beveling. Machines with higher horsepower can handle thicker glass more efficiently.

Another feature to consider is the beveling angle range. Machines that support versatile angles, from 0 to 45 degrees, offer flexibility. This adaptability is essential for various projects. A recent industry report states that 70% of users favor machines with adjustable angles for precision. Additionally, the ease of operation matters. Machines with user-friendly controls can significantly reduce the learning curve.

Tips: Always verify the machine's warranty. A good warranty provides peace of mind. Check the availability of replacement parts. It's beneficial if parts can be easily sourced. Reflect on your specific needs before making a purchase. Consider how frequently you will use the machine and the types of projects you're tackling. This will guide you toward the ideal choice.

Key Features to Consider When Selecting a Beveling Machine

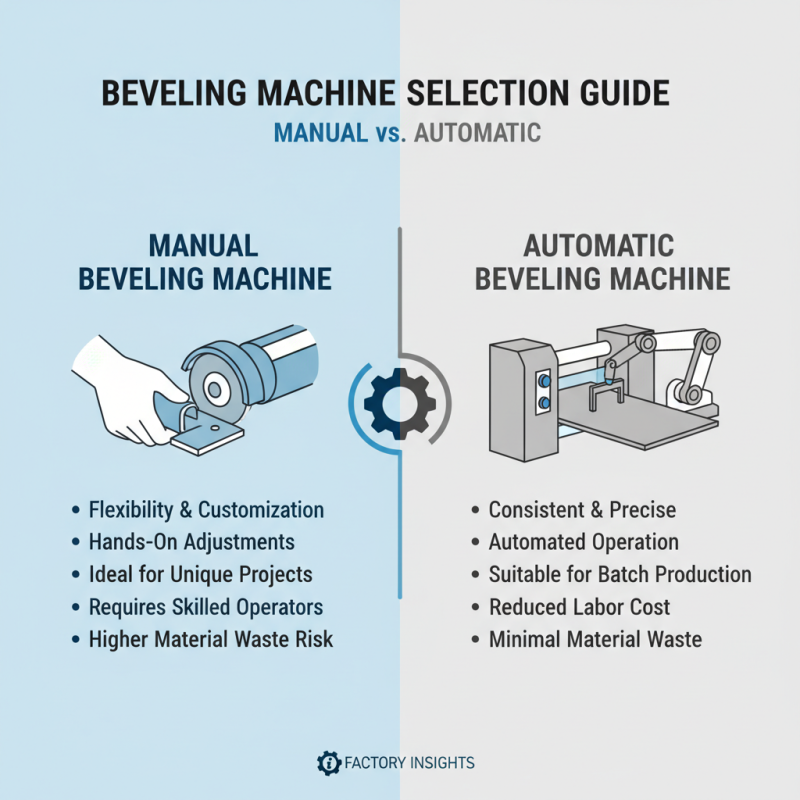

Comparison of Manual vs. Automatic Beveling Machines

When choosing between manual and automatic beveling machines, it's essential to consider your specific needs. Manual machines offer flexibility. They allow for hands-on adjustments, making them ideal for custom projects. However, they require skilled operators who can achieve precise angles and smooth edges. Mistakes can lead to wasted materials.

Automatic beveling machines provide speed and consistency. They are great for high-volume production. These machines often come with advanced features that ensure uniformity across all pieces. However, they may lack the adaptability needed for unique projects. If your business involves varied glass shapes, an automatic option might not be sufficient.

Some users find automatic machines challenging at first. The learning curve can be steep without adequate training. On the other hand, manual machines require constant attention, which can be tiring. It's worth weighing these factors carefully. A machine that excels in one area may fall short in another. Consider your workflow, budget, and skill level before making a decision.

Evaluating Cost vs. Quality in Beveling Machine Selection

When selecting a glass shape beveling machine, cost and quality are crucial factors. According to a recent industry report, nearly 70% of manufacturers prioritize quality over cost when making purchasing decisions. Investing in a high-quality machine often results in better long-term productivity. However, the upfront expense can be daunting for smaller businesses. Balancing these two elements is not easy.

The initial cost of a beveling machine can range significantly. A basic model may start at around $2,000, but advanced machines can exceed $20,000. This price disparity often reflects the quality and durability of the equipment. For instance, machines made from higher-grade materials can handle heavier workloads without frequent breakdowns. Many operators overlook maintenance costs and downtime when evaluating the initial cost. If you're spending less, it might come at a greater long-term expense.

In addition, assessing the machine’s features is essential. Features such as automated controls and speed adjustments can enhance production efficiency. Yet, they may also increase the cost. A machine with basic features may seem budget-friendly but can lead to inefficiencies. Reports suggest that machines with more flexibility often yield a return on investment within the first year of use. It's vital to weigh these factors carefully.

How to Choose the Best Glass Shape Beveling Machine? - Evaluating Cost vs. Quality in Beveling Machine Selection

| Model |

Beveling Angle Range |

Max Glass Thickness |

Power Consumption |

Price Range |

Quality Rating (1-5) |

| Model A |

0° - 45° |

20 mm |

1.5 kW |

$3,500 - $4,000 |

4 |

| Model B |

5° - 50° |

25 mm |

2.0 kW |

$4,500 - $5,000 |

4.5 |

| Model C |

0° - 60° |

30 mm |

2.5 kW |

$5,500 - $6,000 |

5 |

| Model D |

10° - 45° |

15 mm |

1.2 kW |

$2,500 - $3,000 |

3.5 |

Maintenance Tips for Optimal Performance of Beveling Machines

Maintaining a beveling machine is crucial for its longevity and efficiency. Regular cleaning is the foundation of proper care. Dust and debris can accumulate in various parts. A simple wipe-down after each use can prevent buildup. Pay attention to the blades; dull blades affect precision and may lead to accidents. Inspect and sharpen them frequently to ensure optimal performance.

Lubrication is another key factor. Moving parts require adequate lubrication to function smoothly. Check the manufacturer's guidelines for specific oils or greases. Applying the right amount keeps the machine in good shape. Over-lubrication can attract dirt, while under-lubrication leads to wear and tear.

Finally, stay vigilant about machine noise. Unusual sounds might indicate a problem. Addressing these issues early can save time and money later. It’s easy to overlook minor repairs, but they can escalate quickly. Regular maintenance isn’t just about keeping the machine running; it’s about ensuring safety for everyone involved.

Home

About Us

Products

UPVC PVC Window Machine

Aluminum Window Machine

Glass Cutting Machine

Glass Edging Machine

Insulating Glass Machine

Glass lifting machine

Glass Washing Machine

Glass Laminating Machine

Glass Sandblasting Machine

Glass Drilling Machine

CNC Glass Working Center

CNC Non-Metal Cutting Machine

The Other Glass Machinery

Application

Download

News

Contact Us