How to Choose the Best Glass Grinding Machine for Your Needs?

Selecting the right Glass Grinding Machine is crucial for various industries. The global glass processing market is projected to reach $149 billion by 2027, highlighting the demand for efficient grinding solutions. A suitable machine can enhance productivity and reduce waste. However, not all machines fit every business’s needs.

When choosing a Glass Grinding Machine, consider factors like size, power, and technology. Some machines might promise precision but fail in real-world applications. For example, inadequate machinery can lead to increased production costs. Quality matters, yet it's not the only factor; price and service support are vital too.

Many manufacturers boast advanced features. However, it’s essential to focus on your specific requirements. Research indicates that 30% of businesses regret their machine choices due to overspending or misalignment with needs. Reflecting on these elements can lead to better long-term decisions.

Understanding the Different Types of Glass Grinding Machines

When selecting a glass grinding machine, it’s essential to understand the different types available. These machines cater to specific needs and can vary significantly in functionality. There are flat glass grinding machines, which are designed for large sheets of glass. They typically feature various grinding wheels to achieve different finishes.

Then, there are edge grinding machines, ideal for polishing the edges of glass pieces, ensuring safety and aesthetic appeal.

For smaller projects, handheld grinders might be suitable. These are easy to use, allowing for precision work in confined spaces. Users often prefer them for intricate designs. However, they can be less efficient for larger tasks. While thinking about the type of machine, consider your project size and finish requirements. You might hesitate on which machine to choose, but remember that underestimating the power of a suitable machine can lead to frustration.

Each grind type serves a specific function, but the lines can blur. Having the right tool can enhance the quality of work. However, some may find it challenging to determine whether a machine fits their unique needs. Reflecting on past projects might help clarify your choice, ensuring you invest wisely in equipment that meets your expectations.

Key Features to Consider When Selecting a Glass Grinding Machine

When selecting a glass grinding machine, pay attention to its power and speed. These features determine how effectively the machine can handle different glass types. A more powerful motor can grind thicker glass more efficiently. Additionally, adjustable speed settings can cater to various grinding needs. Faster speeds might be better for fine work, while slower speeds suit heavy-duty tasks.

The machine's design is also crucial. Look for features like adjustable tables and easy-to-replace grinding wheels. These can improve accuracy and prolong the tool's lifespan. Many users overlook the importance of dust collection systems. They are essential for maintaining a clean workspace and ensuring visibility during grinding.

Finally, consider the weight of the machine. A heavier machine might seem stable, but it can be cumbersome. Portability may be an issue for a production environment. Always reflect on your specific needs. Take note of what you prioritize: speed, stability, or convenience. Each user may have a different requirement, and what works for one may not work for another.

Assessing Your Specific Glass Grinding Needs and Applications

When assessing your specific glass grinding needs, it is essential to understand the type of glass you will be working with. Are you grinding thick glass sheets, or are you focusing on delicate glassware? Each type requires different approaches. For example, thicker glass may need a more robust machine with higher power, while thinner glass might require a gentler touch to avoid breakage.

Consider the applications you have in mind. Are you creating custom shapes for installations, or do you need precision grinding for stained glass projects? Identifying your primary use will help you select the right features. Variable speeds might be useful for intricate work, while a straightforward option could suffice for larger projects.

Don’t overlook the importance of space and setup. Some machines require ample workspace and ventilation, which may not be feasible in smaller shops. Reflect on your workspace layout before making a decision. Sometimes, the most advertised machines are not the best fit for your specific needs. Always weigh the pros and cons to find what truly serves you best.

How to Choose the Best Glass Grinding Machine for Your Needs?

| Dimension |

Description |

Recommended Use |

Power Source |

| Table Size |

The size of the grinding table that accommodates various glass sizes. |

Large panels, custom glasswork. |

Electric |

| Motor Power |

The power rating of the motor that drives the grinding wheel. |

Heavy-duty grinding. |

Electric |

| Grinding Wheel Type |

The type of grinding wheel used, which affects the finish quality. |

Polishing and shaping glass edges. |

Manual or Electric |

| Water Supply |

Availability of a water supply for cooling the grinding wheel. |

High-volume glass grinding. |

N/A |

| Portability |

Weight and ease of moving the machine. |

Fieldwork and on-site services. |

Manual |

Budgeting for Your Glass Grinding Machine Investment

When budgeting for a glass grinding machine, consider your specific needs. The initial investment can vary significantly based on features and capabilities. A good entry-level model might cost around $2,000. However, more advanced machines can exceed $10,000. Understanding your budget helps in making the right choice.

Set a realistic budget that includes potential additional costs. Look at maintenance expenses and replacement parts. Reports suggest that ongoing costs can account for up to 15% of the initial investment each year. It’s essential to factor in these hidden expenses. This will help you avoid financial surprises.

Tips:

- Research the average lifespan of machines in your price range.

- Reach out to industry professionals for insights.

- Allocate funds for training on the new equipment. Investing in skill development can yield better results in production efficiency.

Think about your long-term plans. Will you need to upgrade soon? Matching the machine's capabilities to your growth plans can be challenging. Stay flexible in your budgeting approach. This adaptability allows room for unexpected changes in your operations.

Maintenance and Support Considerations for Glass Grinding Machines

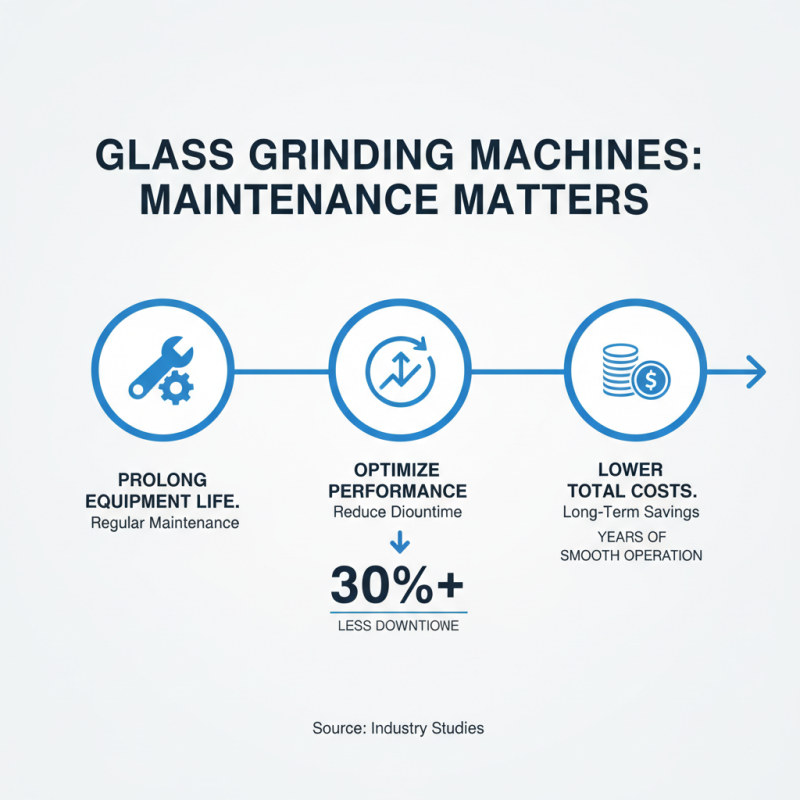

When selecting a glass grinding machine, maintenance and support are critical factors. Regular maintenance can prolong equipment life and optimize performance. Industry studies reveal that over 30% of downtime in production comes from maintenance issues. A machine that is well-maintained can run smoothly for years, reducing total costs in the long run.

Consider the availability of technical support from manufacturers. It's essential to have quick access to support in the event of a malfunction. Reports indicate that 78% of users prioritize responsive customer service when selecting equipment. Adequate training for operators can prevent costly mistakes. Yet, many businesses overlook this aspect, leading to inefficiencies.

Additionally, ensure that replacement parts are readily available. A delay in sourcing parts can cause significant production halts. Over 40% of glass manufacturers experience delays due to unavailability of spare components. Balancing cost with the reliability of support and maintenance is vital. Reflect on your choices; neglecting these aspects can lead to unforeseen challenges.

Home

About Us

Products

UPVC PVC Window Machine

Aluminum Window Machine

Glass Cutting Machine

Glass Edging Machine

Insulating Glass Machine

Glass lifting machine

Glass Washing Machine

Glass Laminating Machine

Glass Sandblasting Machine

Glass Drilling Machine

CNC Glass Working Center

CNC Non-Metal Cutting Machine

The Other Glass Machinery

Application

Download

News

Contact Us