Why Choose a Glass Shape Edging Machine for Your Business?

The glass industry is rapidly evolving. Companies are always looking for ways to enhance their manufacturing processes. A Glass Shape Edging Machine is becoming increasingly crucial. According to a recent market report, the global glass processing machinery market is projected to reach $4 billion by 2025. This growth indicates a rising demand for efficient production tools.

The Glass Shape Edging Machine not only increases productivity but also improves precision. It can handle complex shapes and edges, meeting various customer demands. However, investing in such machinery requires careful consideration. Not every machine may meet your business needs. Assessing the right technology ensures you remain competitive.

While the benefits are clear, some companies still struggle with implementation. Training staff to use advanced machinery poses challenges. Furthermore, maintaining these machines can be costly. Businesses must weigh these aspects against potential gains. A balanced approach is essential for long-term success.

Benefits of Using a Glass Shape Edging Machine in Production

A glass shape edging machine can transform how businesses handle glass production. It enhances efficiency and reduces manual errors. Operators can achieve precise edges consistently, which is essential for high-quality products. Each piece is finished to exact specifications, ensuring that it fits seamlessly in various applications.

Using a glass shape edging machine also improves workflow. It minimizes the time spent on sharpening and adjusting tools. Workers can focus on other tasks, boosting overall productivity.

However, the initial investment can be a concern for some businesses. It requires careful budgeting and planning.

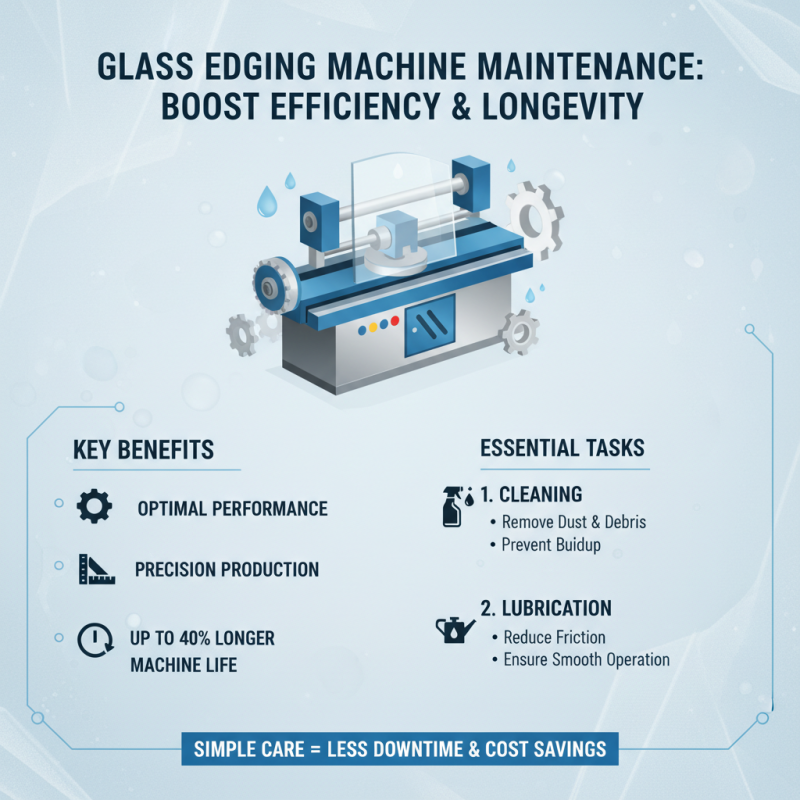

Despite its advantages, operators must continuously monitor machine performance. Regular maintenance is crucial to avoid unforeseen breakdowns. Employees need training to ensure they use the machine correctly. It can be tempting to overlook these aspects in a busy environment. Making these adjustments is vital for long-term success. Each piece of glass produced should reflect the best quality possible.

Key Features to Look for in Glass Shape Edging Machines

When selecting a glass shape edging machine, it's crucial to consider key features that enhance functionality. Look for a robust motor for durability and consistent performance. A higher RPM ensures smooth edging, reducing imperfections. The option for variable speed settings allows you to handle different glass types with precision. This flexibility caters to various projects, from delicate glassware to thicker panels.

Equally important is the machine's safety features. Automatic shut-off functions can prevent accidents during operation. A protective cover helps keep operators safe from flying debris. Also, consider the machine's footprint. Some may be compact yet powerful, ideal for smaller workshops. Others might need more space but offer advanced features.

Reflect on the ease of use. A user-friendly interface can significantly speed up the learning curve. Training staff may take time and resources. However, investing in a machine that is intuitive pays off in efficiency. Regular maintenance requirements are another consideration. Some machines demand frequent checks, while others have self-diagnosing capabilities. Your choice will ultimately shape the quality and output of your glass products.

Why Choose a Glass Shape Edging Machine for Your Business? - Key Features to Look for in Glass Shape Edging Machines

| Feature |

Description |

Benefits |

| Automatic Operation |

Machines that automatically adjust settings for different glass thicknesses. |

Increases efficiency and reduces manual errors. |

| Precision Edging |

Ability to create exact shapes and polished edges. |

Enhances product quality and aesthetic appeal. |

| Versatility |

Can process various types of glass including tempered and laminated glass. |

Allows a wider range of products and applications. |

| Safety Features |

Equipped with protective covers and emergency shut-off systems. |

Ensures operator safety during operation. |

| Maintenance Friendly |

Designed for easy access to components for routine checks. |

Reduces downtime and maintenance costs. |

| Energy Efficiency |

Low power consumption while maintaining performance. |

Decreases operational costs and environmental impact. |

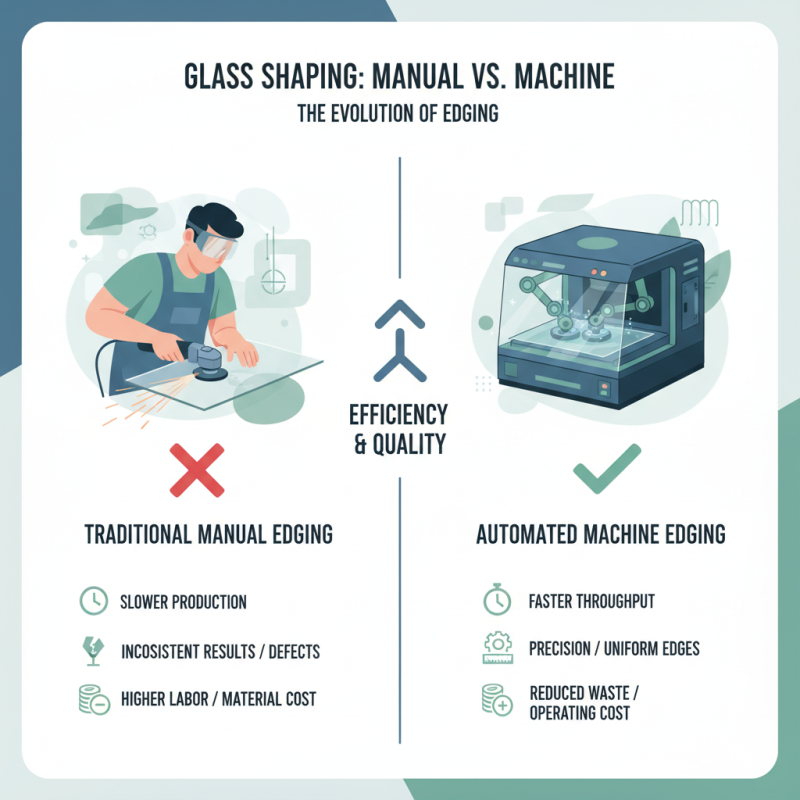

Comparing Glass Shape Edging Machines with Traditional Methods

When comparing glass shape edging machines to traditional methods, several factors emerge. The efficiency of glass shape edging machines is undeniable. These machines process glass quickly and accurately. Unlike manual methods, which are often time-consuming, machines can produce consistent results. Human error can lead to uneven edges or defects, causing delays and extra costs.

Additionally, the flexibility of glass shape edging machines stands out. They can handle various glass shapes and sizes with minimal adjustments. In contrast, traditional methods often require significant reconfiguration for different tasks. This adaptability can increase productivity in a fast-paced environment.

Tips: When choosing a glass edging machine, consider your specific needs. Evaluate the types of glass you work with most often. Look for machines that offer easy maintenance. Regular upkeep can enhance performance and extend the machine's lifespan.

It's essential to reflect on the learning curve with these machines. Some operators might struggle initially. Training is crucial, as familiarity with the equipment can significantly impact overall efficiency. Embrace the challenges, as they often lead to better outcomes in the long run.

Cost-Effectiveness of Investing in a Glass Shape Edging Machine

Investing in a glass shape edging machine can be highly beneficial for businesses in the glass industry. According to a recent industry report, the glass manufacturing market is projected to grow at a CAGR of 5.3% from 2021 to 2026. This growth creates opportunities for companies that can improve their production efficiency. A glass edging machine significantly reduces manual labor and minimizes errors, saving costs over time.

Operational costs can make or break profitability. A study showed that businesses utilizing automated edging machines could cut down labor costs by 30%. That’s a considerable savings margin. Additionally, these machines enhance product quality, leading to fewer returns and higher customer satisfaction. Clients often look for precision in glass products. It’s important to meet these expectations steadily.

Some businesses hesitate to invest because of initial costs. However, the long-term gains may outweigh these upfront investments. Machines wearable for diverse shapes can be more valuable, but choices vary. An upgrade could necessitate consideration of space and maintenance. Every decision should align with business goals for sustainable growth.

Home

About Us

Products

UPVC PVC Window Machine

Aluminum Window Machine

Glass Cutting Machine

Glass Edging Machine

Insulating Glass Machine

Glass lifting machine

Glass Washing Machine

Glass Laminating Machine

Glass Sandblasting Machine

Glass Drilling Machine

CNC Glass Working Center

CNC Non-Metal Cutting Machine

The Other Glass Machinery

Application

Download

News

Contact Us