Why Choose a CNC Glass Milling Machine for Your Business?

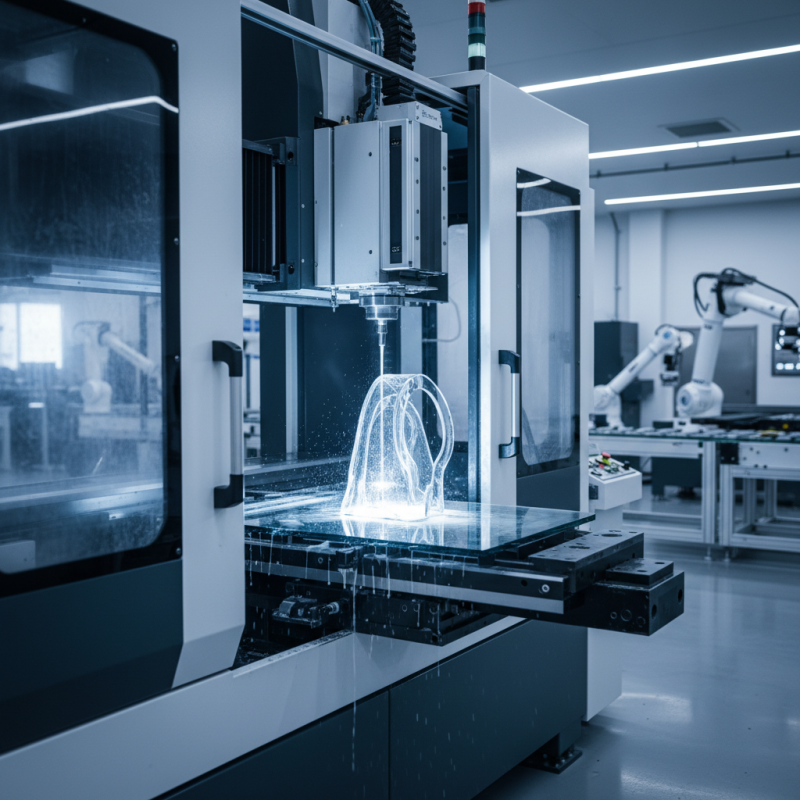

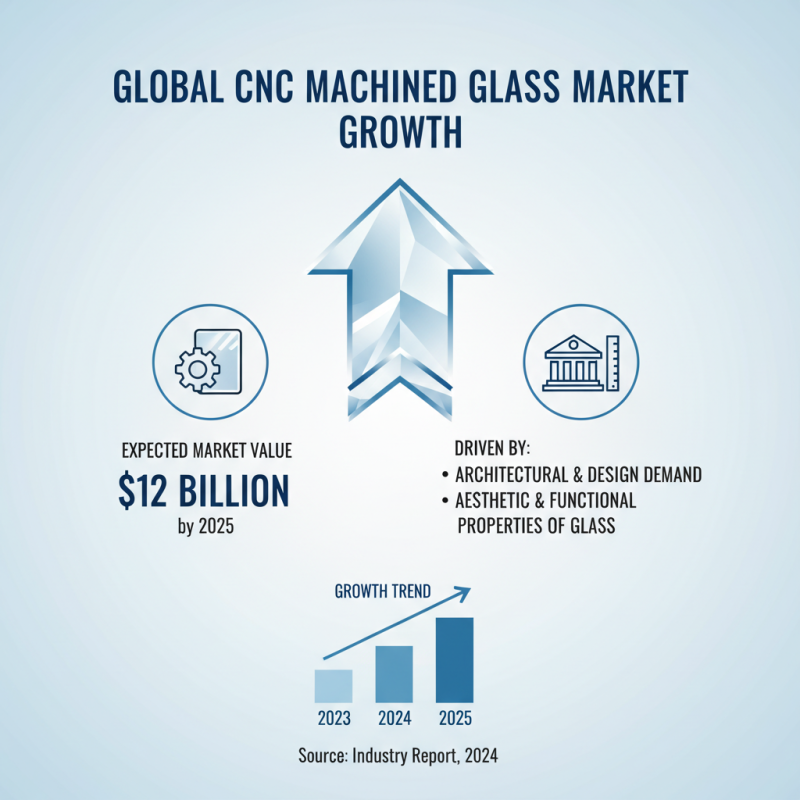

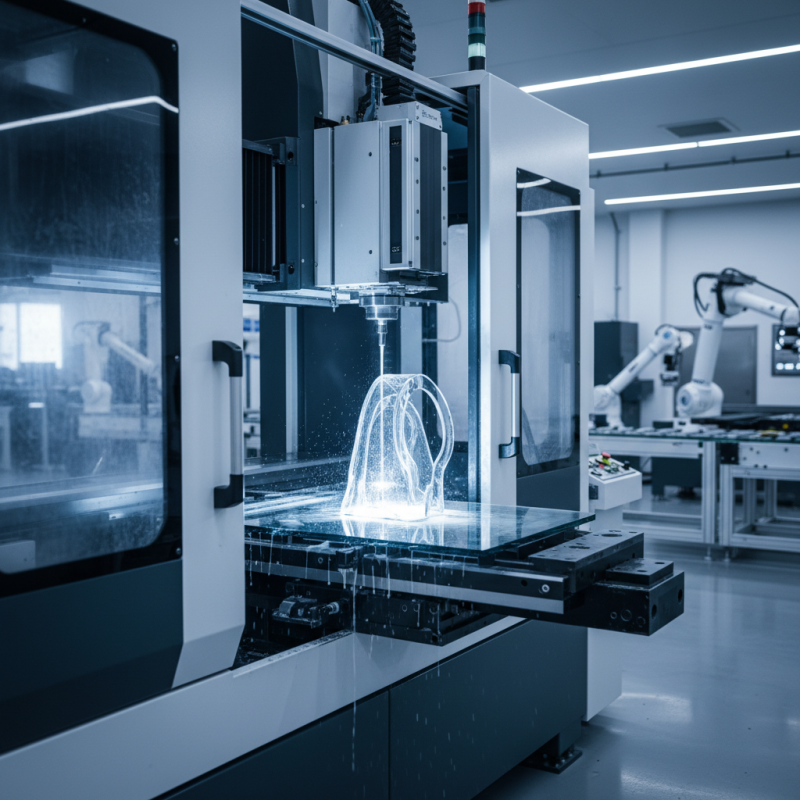

In the evolving landscape of manufacturing, a CNC Glass Milling Machine has become essential for many businesses. Reports show that the global CNC machine market is expected to reach over $100 billion by 2025. This growth highlights the increasing demand for precision and efficiency in production processes. A CNC glass milling machine can provide unmatched accuracy, which is vital in industries like aerospace and telecommunications.

Investing in a CNC glass milling machine can also pave the way for enhanced productivity. Businesses often find that they can reduce manual labor while increasing output. However, the initial investment can be daunting, and some companies struggle to adapt to this technology. Employees may require extensive training, which can disrupt existing workflows. It's crucial to balance these challenges with the long-term benefits.

Utilizing a CNC glass milling machine allows for intricate designs that traditional methods cannot achieve. Customization and rapid prototyping become effortless, leaving businesses more agile in a competitive market. Nevertheless, companies must continuously evaluate their capabilities and the technology’s impact on their operations to fully realize its potential.

Benefits of CNC Glass Milling Machines for Precision Manufacturing

CNC glass milling machines are transforming the manufacturing landscape. These machines offer unmatched precision, which is crucial for any business that relies on glass components. According to a recent industry report, the demand for high-precision glass products is expected to grow by 7% annually. This trend highlights the need for accurate machining techniques.

Precision manufacturing with CNC technology ensures minimal waste. This is crucial in an industry where glass can be expensive. With CNC glass milling, thickness variations can be controlled to within 0.01 mm, ensuring high-quality outputs. However, achieving consistent performance takes practice and understanding of the machine’s capabilities. Operators should continually refine their skills for optimal results.

Tips: Invest in quality training for your staff. It can significantly impact efficiency. Understanding machine settings leads to better production outcomes. Regular maintenance checks are also vital. A small issue can lead to significant downtimes. Remember, even minor imperfections in milling can affect final products. So, pay attention to detail.

Key Features of CNC Glass Milling Machines to Improve Efficiency

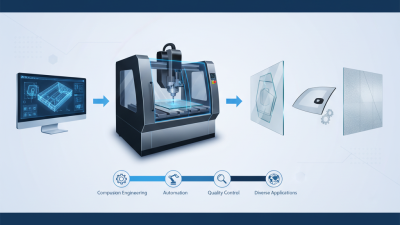

CNC glass milling machines have become essential tools in modern manufacturing. These machines offer precision and versatility. One key feature is their ability to create complex shapes. This allows businesses to meet diverse customer needs. Additionally, they provide a smooth finish on glass surfaces. This quality is vital in aesthetics and functionality.

Another significant advantage is speed. CNC machines operate faster than manual methods. This increase in production efficiency can lead to cost savings. However, it requires careful calibration. If not set correctly, issues like irregular edges may occur. Regular maintenance is necessary to avoid unexpected breakdowns.

Moreover, user-friendly interfaces simplify operation. Operators can quickly program tasks, reducing training time. Yet, reliance on technology might have downsides. Operators may overlook manual skills that are still useful. Finding the right balance between automation and craftsmanship is crucial for long-term success.

Key Features of CNC Glass Milling Machines to Improve Efficiency

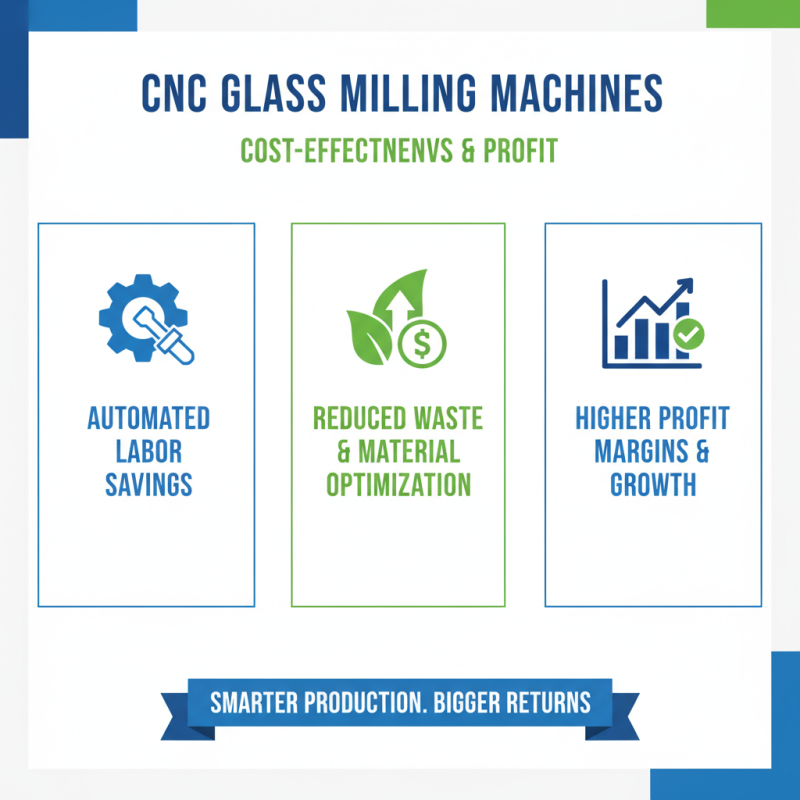

Cost-Effectiveness of CNC Glass Milling Machines for Business Growth

CNC glass milling machines offer remarkable cost-effectiveness. By automating the glass milling process, businesses can save on labor costs. This technology reduces waste, optimizing material use. Lower waste means higher profit margins, which is crucial for growth.

Upfront investment may seem high. However, consider the long-term advantages. Less downtime and faster production times can yield better returns. Companies can complete more projects in less time. This efficiency can enhance competitiveness in the market.

Some may overlook the importance of precision. A well-calibrated CNC glass milling machine ensures consistency in production. This can lead to fewer mistakes and reworks. But, regular maintenance is key. Neglecting this aspect may result in unexpected costs and downtime. Reflection on operational processes can help maximize efficiency and minimize errors, ensuring sustained growth.

Comparative Analysis: CNC Glass Milling vs. Traditional Glass Processing Methods

CNC glass milling machines provide precision that traditional methods often lack. Traditional glass processing relies on hand tools, which can be inconsistent. Human error is common. This can lead to variations in thickness and design flaws. CNC machines, however, follow programmed instructions. They offer uniformity and make intricate designs easily achievable.

One must consider the learning curve, though. Operating CNC machines requires training. Not every worker may adapt quickly. Additionally, the initial investment can be high. Some businesses might hesitate due to costs. Yet, once the machine is operational, the efficiency gained is notable. Faster production times mean more orders can be fulfilled. The right choice could lead to significant growth.

Traditional methods have their charm. Handcrafted pieces often resonate with customers seeking uniqueness. Balancing these methods is crucial for many businesses. Combining both can appeal to a broader market while maintaining quality. Still, as technology advances, the trend leans heavily towards CNC solutions for those who prioritize consistency.

Why Choose a CNC Glass Milling Machine for Your Business?

| Aspect |

CNC Glass Milling |

Traditional Glass Processing |

| Precision |

High precision with tolerances of ±0.01 mm |

Lower precision, typically ±0.1 mm |

| Production Speed |

Faster, capable of 3D milling |

Slower, manual adjustments needed |

| Material Waste |

Less waste due to precise cutting paths |

More waste, less efficient material use |

| Labor Requirement |

Reduced labor with automation |

High labor dependency, more manual work |

| Flexibility |

High flexibility for custom designs |

Limited flexibility, standard shapes only |

Home

About Us

Products

UPVC PVC Window Machine

Aluminum Window Machine

Glass Cutting Machine

Glass Edging Machine

Insulating Glass Machine

Glass lifting machine

Glass Washing Machine

Glass Laminating Machine

Glass Sandblasting Machine

Glass Drilling Machine

CNC Glass Working Center

CNC Non-Metal Cutting Machine

The Other Glass Machinery

Application

Download

News

Contact Us