Essential Checklist for Choosing the Perfect Glass Cutting Machine

Choosing the right Glass Cutting Machine can significantly impact the efficiency and quality of your glass fabrication projects. With a myriad of options available on the market, it’s essential to have a clear understanding of what features and specifications matter most to you. From blade types and cutting speed to automation levels and safety features, the decision-making process can be daunting.

This essential checklist will guide you through the key factors to consider when selecting a Glass Cutting Machine that meets your needs. Whether you are a hobbyist or a professional in the glass industry, the right machine can enhance your precision and productivity, making it easier to achieve flawless cuts every time.

Let’s dive into the tips that will help you navigate your choices and find the perfect machine for your projects.

Key Factors to Consider When Selecting a Glass Cutting Machine

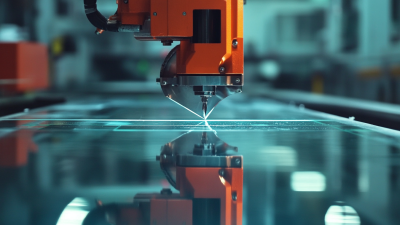

When selecting the perfect glass cutting machine, it's essential to consider several key factors that can significantly influence your choice. Firstly, the machine's cutting capacity and precision are paramount. A higher cutting capacity allows for various thicknesses of glass, while precision ensures clean and efficient cuts, minimizing material waste. Assessing the technology used in the machine, such as whether it's manual or CNC-operated, can also affect the level of control and automation you require for your projects.

Additionally, the size and weight of the glass cutting machine play a crucial role, especially if storage and portability are concerns. Look for machines that offer versatility in their design, as this can enhance usability across different glass types and thicknesses. Another important factor is the brand reputation and customer service; selecting a well-reviewed manufacturer often translates to better support and reliability. Investing time in understanding these key elements can lead you to the glass cutting machine that best suits your needs and enhances your production efficiency.

Comparing Manual vs. Automatic Glass Cutting Machines

When choosing a glass cutting machine, it's crucial to weigh the advantages of manual versus automatic systems. Manual glass cutting machines have long been favored for their simplicity and cost-effectiveness, often appealing to small workshops and hobbyists. According to a report from Market Research Future, the demand for manual glass cutting tools is expected to grow by 6% annually due to their ease of use and lower initial investment. These machines allow operators to maintain a hands-on approach, giving precise control over cuts, which is essential for intricate designs.

On the other hand, automatic glass cutting machines are revolutionizing the industry with their efficiency and precision. A study by Technavio predicts that the automatic glass cutting machine market will see significant growth, outpacing manual systems by a rate of 8% annually. These machines reduce human error, increase production rates, and lower labor costs in high-volume scenarios. For larger operations, implementing CNC (Computer Numerical Control) cutting systems can lead to significant operational savings, as they can process large sheets of glass in a fraction of the time it takes manual machines. Thus, the choice between manual and automatic glass cutting machines hinges on the specific needs and scale of your operations.

Essential Features for Precision and Efficiency in Glass Cutting

When selecting the perfect glass cutting machine, precision and efficiency stand out as the most critical features to consider. According to a recent industry report by Grand View Research, the global glass processing machinery market is projected to reach $7.6 billion by 2028, driven by advancements in technology that enhance precision and speed. A machine that offers high-cutting accuracy ensures that every piece of glass is produced with minimal waste, saving both time and materials. Look for machines that provide adjustable cutting speeds and automatic feed systems, which can dramatically increase productivity.

Additionally, energy efficiency has become a significant factor for industry leaders. The International Energy Agency reports that modern glass cutting machines can operate at up to 30% higher efficiency compared to older models. Machines equipped with features like intelligent control systems not only reduce power consumption but also allow operators to maximize throughput without sacrificing quality. By prioritizing these essential features, manufacturers can improve their overall production capacity and maintain competitive advantages in an increasingly demanding market.

Essential Checklist for Choosing the Perfect Glass Cutting Machine

Cost Considerations: Finding a Glass Cutter that Fits Your Budget

When selecting a glass cutting machine, budget considerations are paramount. According to the latest report from the Glass Association, prices for glass cutting machines can range significantly, from $200 for entry-level models to over $5,000 for advanced industrial options. This broad spectrum means that a thorough assessment of your budget constraints is essential. It's crucial to align features and capabilities with the intended use, ensuring you don’t overspend on features that may be unnecessary for your specific needs.

Furthermore, maintenance and operational costs should also be factored into your budget. A study by the International Glass Industry noted that while lower-priced machines may have a lower upfront cost, the long-term expenses—such as replacement parts, specialized blades, and energy consumption—can significantly impact overall costs. For professionals or businesses, investing a bit more in a durable, high-quality machine may yield long-term savings by minimizing downtime and increasing efficiency in production.

Ultimately, wise budgeting will lead to a more informed purchase that balances immediate affordability with long-term operational effectiveness.

Tips for Maintaining Your Glass Cutting Machine for Longevity

When investing in a glass cutting machine, maintenance is key to ensuring its longevity and optimal performance. First and foremost, regular cleaning is essential. After each use, make sure to remove all glass fragments and dust from the machine's surfaces and cutting area. Using a soft brush or a vacuum can help prevent debris buildup, which can interfere with the cutting process and compromise the quality of your cuts. Additionally, lubrication of moving parts is crucial. Regularly check the manufacturer's guidelines for recommended lubricants and keep the cutting wheels and other components well-greased to ensure smooth operation.

Another important aspect of maintenance is periodic inspection of the cutting blades. Over time, blades can dull or become chipped, leading to less accurate cuts and requiring more effort during operation. Regularly inspect the blades for wear and replace them as needed. Also, consider the environment where the machine is stored; keeping it in a dry, temperature-controlled area can prevent rust and corrosion. By being proactive about maintenance, you can significantly extend the life of your glass cutting machine and ensure that it remains a reliable tool for your projects.

Essential Checklist for Choosing the Perfect Glass Cutting Machine - Tips for Maintaining Your Glass Cutting Machine for Longevity

| Feature |

Importance |

Maintenance Tips |

| Blade Quality |

Critical for clean cuts |

Regularly check for wear; replace as necessary |

| Cutting Speed |

Affects efficiency and precision |

Adjust settings based on material type |

| Ease of Use |

Impacts training time |

Keep user manual accessible; train operators |

| Weight and Portability |

Affects location flexibility |

Store in a designated area; handle carefully |

| Safety Features |

Prevents accidents |

Regularly inspect and test safety mechanisms |

Home

About Us

Products

UPVC PVC Window Machine

Aluminum Window Machine

Glass Cutting Machine

Glass Edging Machine

Insulating Glass Machine

Glass lifting machine

Glass Washing Machine

Glass Laminating Machine

Glass Sandblasting Machine

Glass Drilling Machine

CNC Glass Working Center

CNC Non-Metal Cutting Machine

The Other Glass Machinery

Application

Download

News

Contact Us