Challenges Faced with Best Glass Edge Grinding Machine Efficiency

As the glass manufacturing industry continues to evolve, the importance of efficiency in processes such as edge grinding has never been more paramount. According to a recent report by the International Glass Association, the global market for glass processing machinery is projected to reach $6 billion by 2025, with a significant portion attributed to advanced technologies in glass edge grinding machines.

These sophisticated tools are integral in achieving high precision and quality, yet companies face numerous challenges, including equipment maintenance, energy consumption, and skilled labor shortages. Addressing these factors is crucial for maximizing the efficiency of glass edge grinding machines, ultimately leading to improved profitability and competitiveness in the marketplace.

Understanding the intricacies of these challenges not only helps manufacturers streamline operations but also enhances the overall quality of finished glass products.

Challenges in Achieving Optimal Efficiency with Glass Edge Grinding Machines

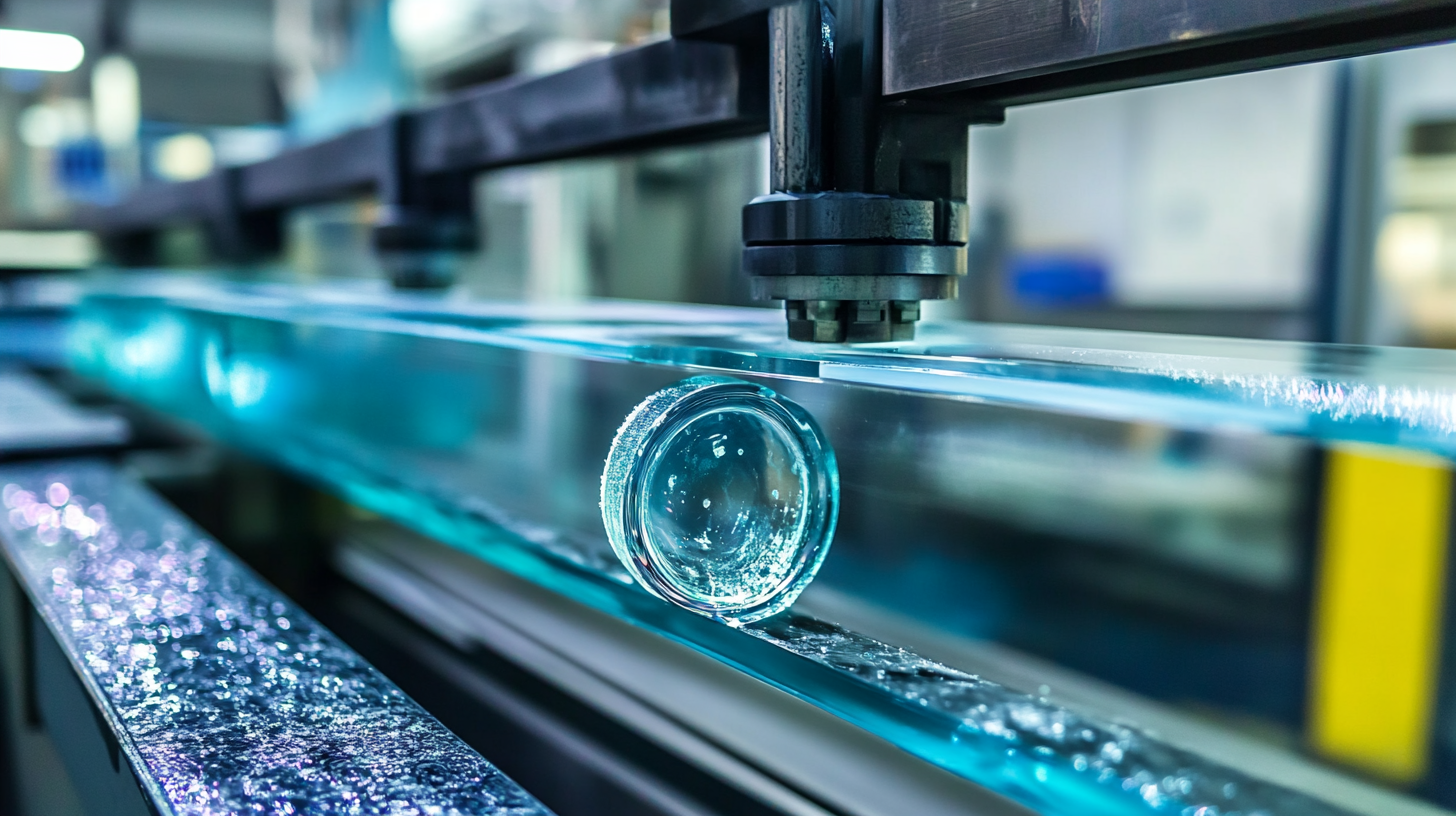

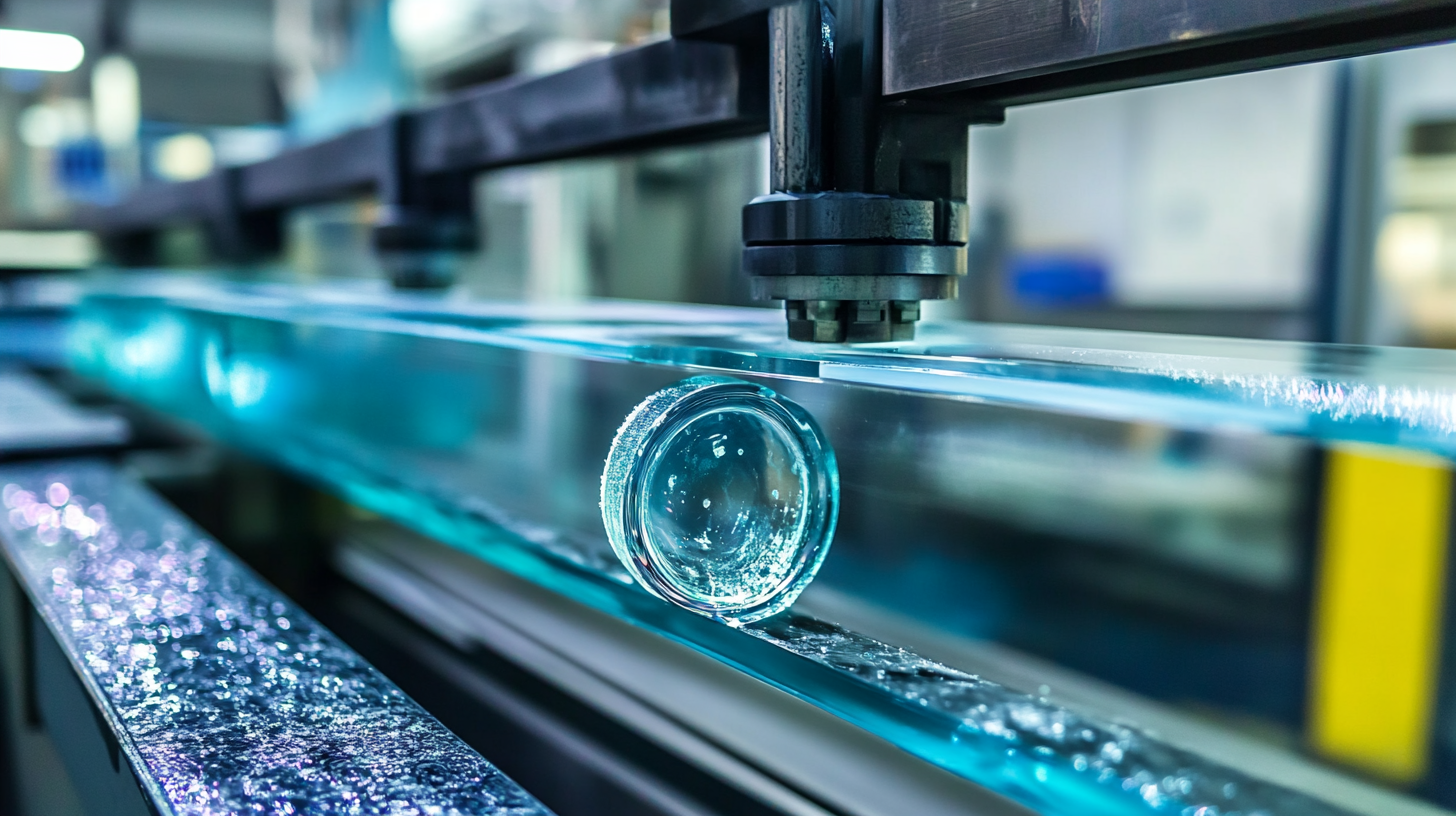

Achieving optimal efficiency with glass edge grinding machines presents several challenges that manufacturers must navigate. Variability in glass thickness and composition can lead to inconsistent grinding outcomes, affecting both the quality and productivity of the operation.

Furthermore, issues such as overheating and tool wear can significantly hinder performance, requiring careful monitoring and maintenance to maintain an ideal operational standard.

Furthermore, issues such as overheating and tool wear can significantly hinder performance, requiring careful monitoring and maintenance to maintain an ideal operational standard.

To combat these challenges, operators should focus on implementing regular maintenance schedules for their machines. This not only helps in prolonging the lifespan of grinding tools but also ensures consistent performance. Additionally, using high-quality abrasive materials designed specifically for glass can improve efficiency and reduce the frequency of machine downtime.

Another important tip is to invest in training for operators. Well-trained staff can identify potential issues early and optimize machine settings according to the specific characteristics of the glass being processed. This understanding can lead to more precise grinding and enhanced overall efficiency, ultimately benefiting production timelines and quality control.

Key Factors Impacting Glass Edge Grinding Machine Performance

The efficiency of glass edge grinding machines is heavily influenced by several key factors. According to a report by the Glass Machinery Manufacturers Association,

the precision of the grinding tool and its material significantly impact the overall grinding performance.

High-quality diamond grinding wheels, for instance, can increase production efficiency by up to 30%, resulting in better edge quality while reducing processing times.

Therefore, investing in superior tooling is crucial for manufacturers aiming to improve their output.

Another critical factor is the machine's operational settings, including speed, feed rate, and water cooling mechanisms.

A study conducted by the International Journal of Glass Science highlighted that optimizing these parameters can enhance the grinding process, yielding smoother edges and less wear on the machine components.

Typically, machines that operate at a higher speed combined with a tailored feed rate see a substantial decrease in cycle time, which can be as much as 20%.

Adapting these settings based on the thickness and type of glass being processed allows for more effective grinding, directly impacting productivity and cost efficiency in the glass manufacturing sector.

Statistical Insights: Productivity Rates of Glass Edge Grinding Processes

The efficiency of glass edge grinding machines is vital for maximizing productivity in the glass manufacturing industry. Recent statistical insights indicate that the average productivity rate for glass edge grinding processes can vary significantly, with high-performing machines achieving output rates of up to 300 linear meters of glass processed per hour. This substantial difference points to the importance of selecting the right machine to ensure optimal performance and minimize downtime.

Further analysis reveals that factors such as machine maintenance and operator skill levels play a crucial role in influencing productivity rates. Data from the Glass Association International shows that well-maintained edge grinding machines can operate at a 25% higher efficiency compared to those that are not routinely serviced. Additionally, operator training programs have been shown to enhance productivity by up to 15%, suggesting that investments in workforce education can lead to substantial gains in overall machine efficiency.

Thus, understanding these statistical insights is crucial for manufacturers looking to enhance their glass edge grinding processes and improve competitive standing in the market.

Common Technical Issues Leading to Reduced Grinding Efficiency

In the glass processing industry, achieving optimal efficiency with edge grinding machines is paramount for productivity and cost-effectiveness. However, several common technical issues can lead to a significant reduction in grinding efficiency. According to a recent report by the Glass Association, inefficiencies in machinery can account for up to 30% of production time lost, primarily due to improper calibration and maintenance. When the grinding wheels are not aligned correctly or show signs of wear, the resulting vibrations and uneven grinding can lead to subpar edge finishes and increased rework.

Another factor contributing to reduced efficiency is the choice of grinding materials. Studies have shown that using lower-quality abrasives can result in excessive wear on grinding machinery, causing downtime and costly repairs. The International Journal of Glass Processing highlights that utilizing high-grade diamond tools can extend the lifespan of grinding machines by up to 50%, ultimately improving overall throughput. Furthermore, neglecting preventive maintenance schedules exacerbates these issues, as machines left unchecked are prone to more frequent breakdowns, which can disrupt workflow and inflate production costs. Addressing these technical challenges is essential for maximizing the efficiency of glass edge grinding operations.

Emerging Technologies to Enhance Glass Edge Grinding Operations

The glass edge grinding industry faces various challenges that impact efficiency, but emerging technologies are beginning to transform these operations significantly. One of the most noteworthy advancements is the integration of automation and robotics into the grinding process. Automated systems can work continuously without fatigue, ensuring consistent quality and reducing human error. This technology not only enhances precision but also allows for higher production rates, addressing one of the biggest bottlenecks in traditional grinding methods.

Another promising innovation is the use of advanced materials and coatings for grinding wheels and machinery components. These materials are designed to withstand higher temperatures and abrasiveness, leading to a longer lifespan and reduced need for frequent replacements. Additionally, software solutions powered by artificial intelligence are helping operators optimize grinding parameters in real-time, resulting in improved efficiency and better quality finishes. By embracing these emerging technologies, glass manufacturers can meet the increasing demand for high-quality products while minimizing operational costs and maximizing productivity.

Home

About Us

Products

UPVC PVC Window Machine

Aluminum Window Machine

Glass Cutting Machine

Glass Edging Machine

Insulating Glass Machine

Glass lifting machine

Glass Washing Machine

Glass Laminating Machine

Glass Sandblasting Machine

Glass Drilling Machine

CNC Glass Working Center

CNC Non-Metal Cutting Machine

The Other Glass Machinery

Application

Download

News

Contact Us

Furthermore, issues such as overheating and tool wear can significantly hinder performance, requiring careful monitoring and maintenance to maintain an ideal operational standard.

Furthermore, issues such as overheating and tool wear can significantly hinder performance, requiring careful monitoring and maintenance to maintain an ideal operational standard.