Best Glass Edging Processing Machine for 2026 What to Choose?

The glass industry is evolving rapidly, and choosing the right Glass Edging Processing Machine is crucial for success in 2026. Industry expert Dr. John Becker emphasizes, “The right machine can elevate your production quality and efficiency.” With advancements in technology, an array of options is available, each suited for different applications.

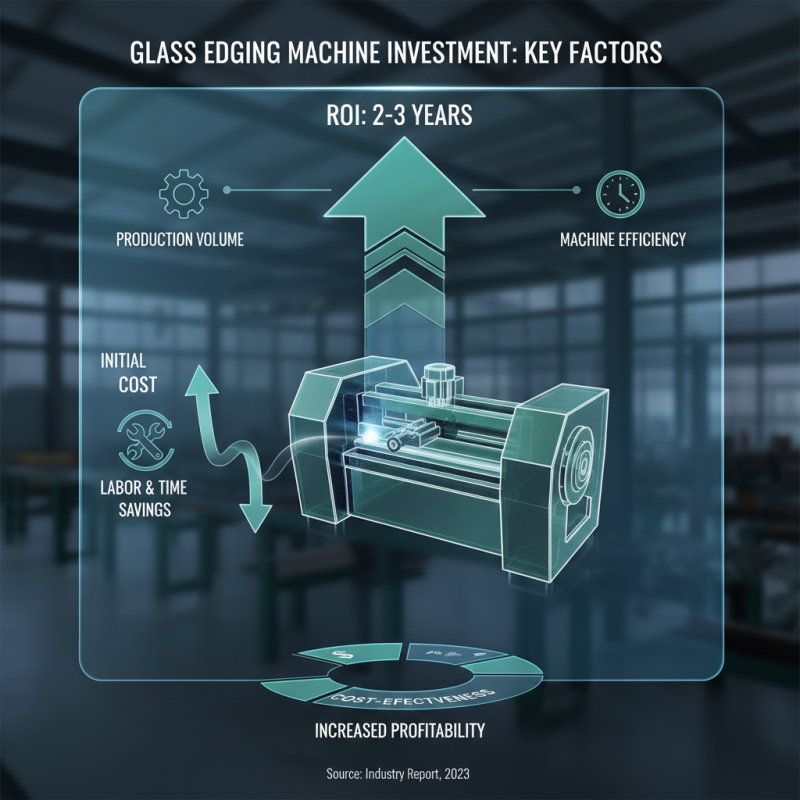

Selecting a suitable machine requires careful consideration. Factors like production volume, glass thickness, and desired edge quality must be evaluated. High-quality edging machines are not just about speed; they also ensure precision and reliability. However, many businesses often overlook this, resulting in poor performance and costly mistakes. It’s essential to reflect on past choices to avoid repeating them.

Moreover, it’s key to balance budget constraints with functionality. Investing in a top-tier Glass Edging Processing Machine can seem daunting. But, as Dr. Becker states, “Quality never goes out of style.” Taking the time to research and consult with experts can lead to a decision that pays off for years to come.

Best Glass Edging Processing Machines: An Overview of Current Technologies

In the world of glass processing, edging machines play a vital role. These machines ensure precise and clean edges for varied glass applications. Current technologies focus on efficiency and accuracy. Many machines now integrate automation. This reduces human error and speeds up production. Additionally, some offer customizable options for different glass thicknesses.

When choosing a glass edging machine, consider its speed and versatility. A machine that can handle various edge profiles may serve you better in the long run. Be aware, however, that complexity can lead to higher maintenance needs. Always check if the machine offers easy access for repair. This could save you time and costs later.

**Tip:** Regular training for operators can improve productivity. Familiarity with the machine enhances its efficiency. Additionally, invest in routine maintenance. This helps avoid breakdowns. Evaluate your production needs carefully before making a final decision. The right machine can make a significant difference in your output. Take the time to understand your specific requirements.

Best Glass Edging Processing Machines for 2026

| Model |

Edge Type |

Max Thickness (mm) |

Speed (m/min) |

Automation Level |

Price Range (USD) |

| Model A |

Flat Edge |

19 |

10 |

Fully Automatic |

$25,000 - $30,000 |

| Model B |

Bevel Edge |

15 |

12 |

Semi-Automatic |

$20,000 - $25,000 |

| Model C |

Polished Edge |

25 |

8 |

Fully Automatic |

$30,000 - $35,000 |

| Model D |

Flat Edge |

12 |

15 |

Manual |

$10,000 - $15,000 |

Key Features to Look for in Glass Edging Machines for 2026

When selecting a glass edging machine for 2026, several key features should be prioritized. A reliable machine should offer versatility in edge profiles. Different jobs may require various edge finishes. This flexibility is essential for meeting diverse customer needs.

Ease of use is another crucial aspect. Operators should feel comfortable with controls and settings. Complicated interfaces can lead to errors and inefficiencies.

Another important feature is the machine's durability. Glass processing is demanding, and machines should withstand rigorous use. Though some models claim enhanced longevity, real-world performance often reveals flaws. Regular maintenance and servicing can be a hassle.

Efficiency is vital in glass production. Speed and productivity must not compromise quality. Machines that frequently malfunction can disrupt workflows. Look for user reviews to assess performance over time. The best choice balances speed, precision, and ease of maintenance. An informed decision requires careful consideration and sometimes, a willingness to adapt.

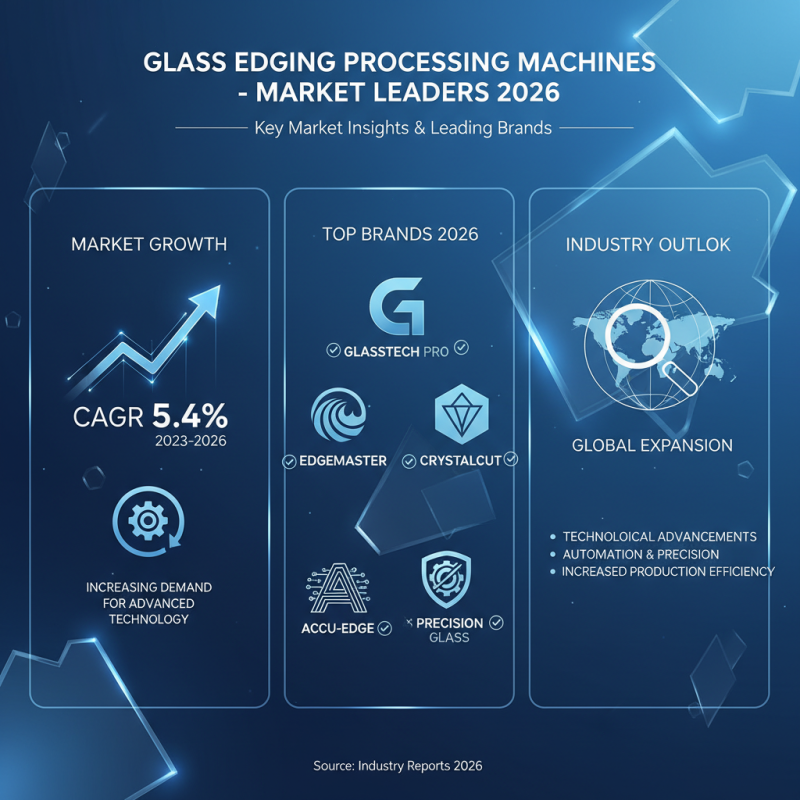

Comparative Analysis of Leading Glass Edging Brands and Their Market Impact

In the competitive landscape of glass edging processing machines, several brands stand out in 2026. Their impact on the market has been significant, highlighting the need for comprehensive analysis. Recent reports indicate that the glass processing market is expected to grow at a CAGR of 5.4% through 2026. This suggests an increasing demand for advanced technology in edging machines.

When examining leading brands, consider their innovation features. Some machines offer automated edging processes, reducing labor costs and enhancing precision. However, not all brands prioritize durability. A few models struggle with maintenance and reliability, which could lead to increased downtime. The industry also faces challenges in sourcing high-quality materials. Ensuring quality control in production remains crucial.

Tips: Always assess your specific needs before purchasing. Evaluate the machine's efficiency against your production volume. Reliability is key; research customer reviews and maintenance records. Don't overlook service support, as timely repairs can save considerable costs.

Future Trends in Glass Edging Technology and Industry Innovations

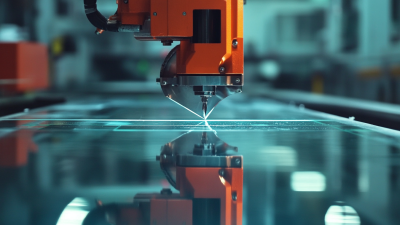

The glass edging industry is evolving rapidly. Innovations in technology are shaping how glass is processed. Automated systems are taking center stage. They enhance precision and reduce waste. The demand for eco-friendly materials is rising. This trend is here to stay.

Tips: Consider energy-efficient machines. They can save costs in the long run. Research emerging techniques, like laser edging, which offers high precision. Always evaluate the machine's adaptability to new trends.

Investors should focus on smart technology integration. It helps streamline operations and improve safety. However, not all machines will meet future demands. There might be bugs in newer software. Ensure proper training for operators to handle these advancements. Embrace change, but be prepared for challenges ahead.

Home

About Us

Products

UPVC PVC Window Machine

Aluminum Window Machine

Glass Cutting Machine

Glass Edging Machine

Insulating Glass Machine

Glass lifting machine

Glass Washing Machine

Glass Laminating Machine

Glass Sandblasting Machine

Glass Drilling Machine

CNC Glass Working Center

CNC Non-Metal Cutting Machine

The Other Glass Machinery

Application

Download

News

Contact Us