What is the Best Glass Edge Polishing Machine for Your Needs?

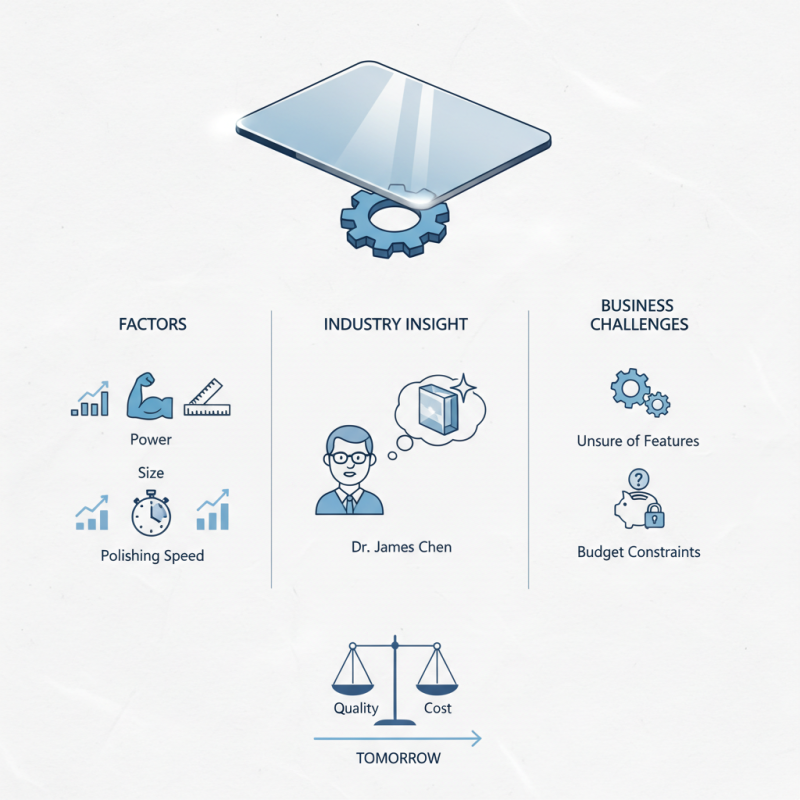

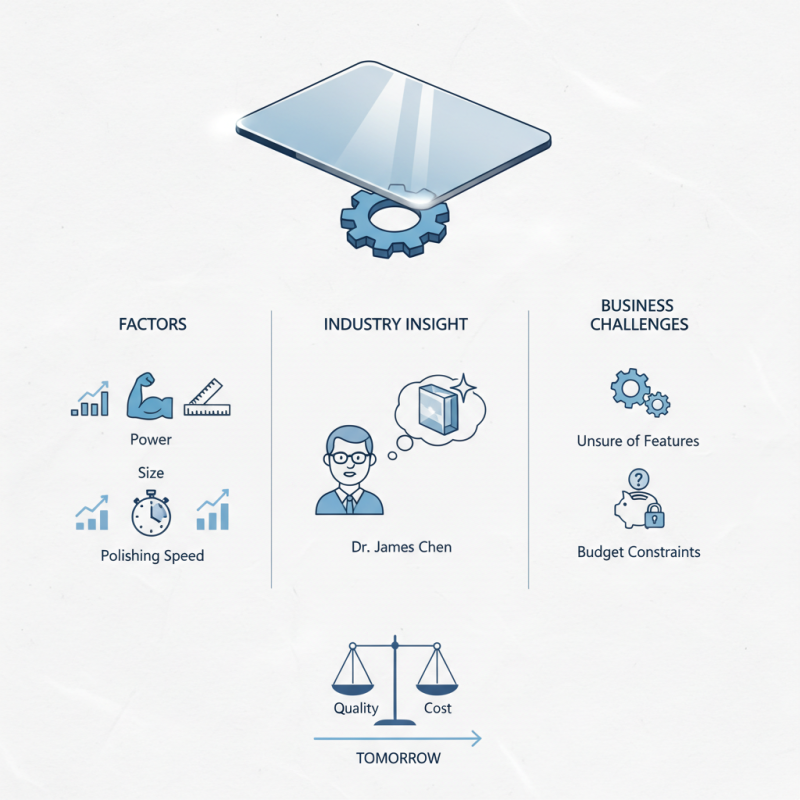

When it comes to selecting the right Glass Edge Polishing Machine, the choices can be overwhelming. Renowned industry expert, Dr. James Chen, once stated, "The quality of your machine directly impacts your final product." His insight reflects a crucial aspect in the glass manufacturing industry.

In recent years, the demand for high-quality glass products has skyrocketed. Consequently, the need for efficient and reliable glass edge polishing machines has become essential. Many manufacturers face challenges in choosing the best machine. Factors such as power, size, and polishing speed come into play. Often, businesses realize they are unsure about which features matter most for their specific needs.

Additionally, budget constraints can complicate the decision process. While some machines promise high efficiency, they may not fit every situation. It's vital to reflect on these choices. The decision you make today will affect your production tomorrow. Selecting the right Glass Edge Polishing Machine requires a careful balance of quality and cost.

Understanding Glass Edge Polishing Machines: Key Features and Functions

Glass edge polishing machines are essential for achieving smooth and polished edges on glass products. These machines come equipped with various features that enhance their functionality. For instance, adjustable speed settings allow users to control the polishing process better. This flexibility ensures that different types of glass can be polished effectively. The ability to work with different edge profiles is also crucial. Some machines offer a range of wheels or pads for various finishes.

When selecting a machine, consider the size and weight. A portable unit may be more suitable for small workshops. However, larger machines often provide stability for bigger production runs. Look for options with dust extraction systems. These systems keep the workspace cleaner and enhance visibility. Safety features are another important aspect. Operators should ensure proper eye protection and avoid contact with moving parts.

While many machines perform well, user experience can vary. Some may find the learning curve steep. Proper training and practice are necessary for optimal results. Additionally, maintenance cannot be overlooked. Regular checks and adjustments will keep the machine functioning smoothly. Users should keep in mind that even the best machines may not eliminate the need for manual touch-ups. Understanding these nuances can lead to better choices in glass edge polishing.

Types of Glass Edge Polishing Machines: Choosing the Right Fit for Your Project

When it comes to glass edge polishing machines, there are several types to consider. Each type serves different purposes, depending on your project needs. For instance, a manual edge polisher is great for small jobs. It's less expensive and allows for precise control. However, it can be time-consuming and physically demanding.

On the other hand, an automatic edge polishing machine increases efficiency significantly. These machines are perfect for larger projects, providing uniform finishes. But they require a higher initial investment and some technical knowledge. Choose wisely based on your project size and budget.

Tips: Always assess the size of your workspace. A bulky machine may not fit well in smaller shops. Additionally, consider the types of glass you will be working with. Some machines handle thicker glass better than others. Don't overlook the importance of safety features, as working with glass can be hazardous. Stay informed and learn from the experiences of others, as improvement comes from reflection and practice.

Technical Specifications: What to Look for in a Polishing Machine

When selecting a glass edge polishing machine, technical specifications are crucial. Pay attention to horsepower (HP) ratings. Machines with higher HP can handle thicker glass more effectively. Typically, a 1 to 5 HP motor is preferred for moderate to heavy-duty polishing tasks. This range often provides the necessary power without compromising performance.

Speed is another key factor. A variable speed setting allows operators to adjust the polishing process based on their specific project. Machines that can operate between 600 to 2400 RPM offer versatility. This ensures that delicate glass can be polished without risk of breakage.

Weight and portability also matter. Heavier machines often provide stability. However, they can be cumbersome. Lighter models, while easy to maneuver, might vibrate more. A weight range of 50 to 200 pounds is common for industrial machines. Finding a balance is essential. Ultimately, each project may require different specifications, and flexibility can be a game-changer.

Industry Standards: Quality Assurance in Glass Edge Polishing Equipment

When considering glass edge polishing machines, industry standards play a crucial role in ensuring quality. Reports indicate that more than 70% of manufacturers prioritize equipment that meets stringent industry guidelines. These standards are designed to maximize safety and durability, minimizing defects in polished glass edges. Choosing a machine that adheres to these quality assurance protocols is essential. For example, experts recommend looking for machines with certifications that denote compliance with international safety norms. These often guarantee better performance and reduced operational risks. A study noted that using properly certified machines can lower the incidence of hazardous accidents by 50%. Tips: Regular maintenance can also enhance the performance of your polishing machine. Ensure that components are inspected frequently. This can help avoid malfunctions that may lead to subpar polishing results. Additionally, consider operator training as part of your quality assurance strategy. Well-trained staff are less likely to make errors that could compromise glass quality.

What is the Best Glass Edge Polishing Machine for Your Needs?

| Model |

Power (HP) |

Polishing Speed (m/min) |

Weight (kg) |

Price ($) |

| Model A |

3 |

15 |

250 |

2000 |

| Model B |

5 |

20 |

300 |

3000 |

| Model C |

4 |

18 |

270 |

2500 |

| Model D |

6 |

22 |

350 |

3500 |

Cost-Benefit Analysis: Evaluating Investment in Polishing Machinery

Investing in a glass edge polishing machine can be a significant decision. It’s crucial to understand the cost versus the benefits. An upfront high cost often leads to long-term savings. A quality machine increases efficiency and reduces labor costs. Operators can achieve smoother finishes faster, improving overall productivity. However, the initial investment can be daunting for small businesses.

Your specific needs must be assessed carefully. Consider the volume of glass processed weekly. Higher production demands may justify a premium machine. You should also think about maintenance costs. While some machines require minimal upkeep, others might need regular servicing. This could add to your operational costs over time.

It’s easy to overlook these details when searching for a machine. Many buy the latest technology without fully evaluating their needs. Reflection on past purchases is critical. Did I choose a suitable machine last time? Understanding your mistakes may save money in the long run. Choose wisely, and weigh your options. Adjusting to the right choice can make all the difference in your polishing operations.

Cost-Benefit Analysis of Glass Edge Polishing Machines

Home

About Us

Products

UPVC PVC Window Machine

Aluminum Window Machine

Glass Cutting Machine

Glass Edging Machine

Insulating Glass Machine

Glass lifting machine

Glass Washing Machine

Glass Laminating Machine

Glass Sandblasting Machine

Glass Drilling Machine

CNC Glass Working Center

CNC Non-Metal Cutting Machine

The Other Glass Machinery

Application

Download

News

Contact Us