What is the Best Glass Edge Grinding Machine and How Does it Work?

In the glass processing industry, the demand for precision and efficiency has led to significant advancements in machinery, particularly the Glass Edge Grinding Machine. According to a recent market report by Research and Markets, the global glass processing equipment market is projected to grow at a CAGR of over 5% from 2021 to 2026, driven by rising construction activities and increasing demand for glass products in various sectors. This growth underscores the importance of high-quality glass edge grinding machines, which play a crucial role in ensuring smooth finishes and safe handling of glass products. As manufacturers strive for excellence, the evolution of these machines combines advanced technology and careful craftsmanship, making them a cornerstone of the industry. In this blog, we will explore what makes the best Glass Edge Grinding Machine and how these machines function to meet the rigorous demands of modern glass processing.

The Importance of Choosing the Right Glass Edge Grinding Machine for Quality Production

Choosing the right glass edge grinding machine is crucial for ensuring high-quality production in the glass manufacturing industry. According to a report by Grand View Research, the global glass processing machinery market is expected to reach USD 4.9 billion by 2025, driven by the increasing demand for architectural glass and advanced glass products. A reliable glass edge grinding machine can significantly enhance the efficiency and precision of glass finishing processes, leading to better product quality and lower rejection rates.

Moreover, the performance of a glass edge grinding machine directly impacts the final aesthetic and structural integrity of glass products. For instance, machines equipped with advanced automation and CNC technology can optimize grinding angles and improve surface finish, which is essential for applications in the automotive and construction sectors. A study by Research and Markets indicates that the adoption of automated grinding solutions can increase productivity by up to 30%. Thus, selecting the right equipment not only improves the end product but also contributes to overall operational effectiveness and profitability.

Key Features to Look for in Top Glass Edge Grinding Machines

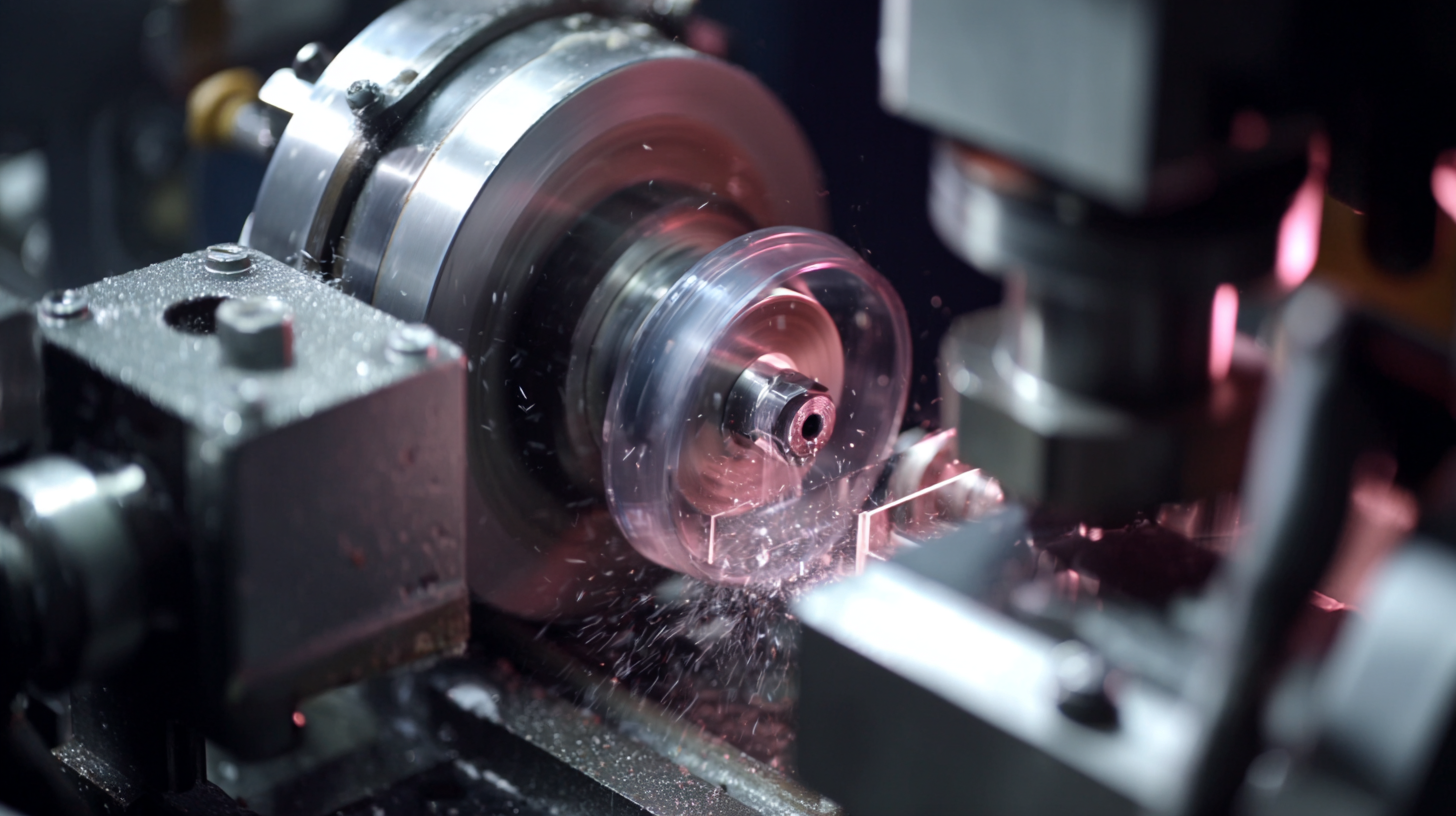

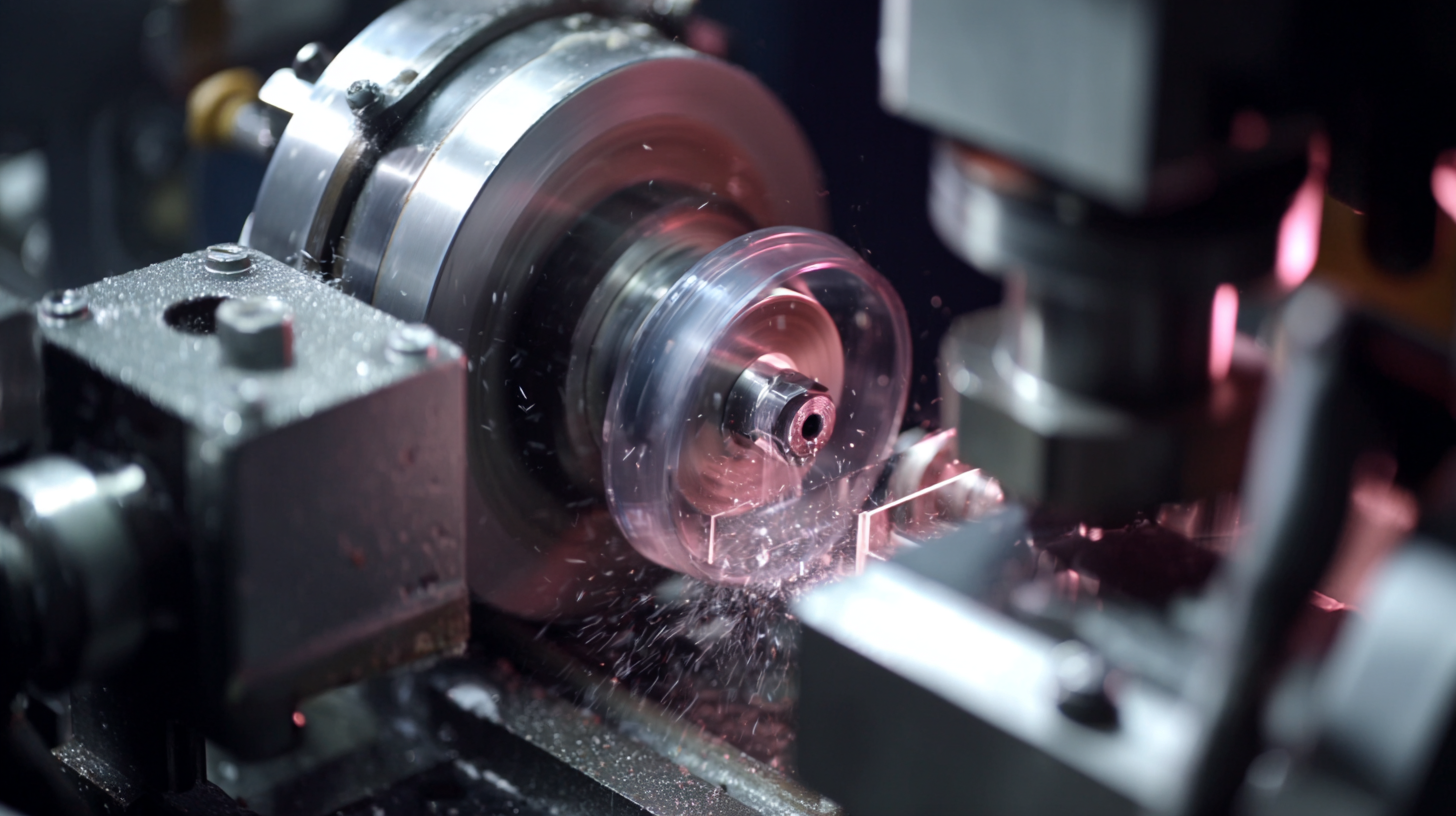

When selecting the best glass edge grinding machine, several key features can significantly influence performance and efficiency. First and foremost, the machine's motor power is crucial. Opt for a model with a robust motor that can handle various types and thicknesses of glass, ensuring smooth and consistent grinding. Additionally, look for machines that offer adjustable speed settings; this flexibility allows for fine-tuning to suit specific grinding tasks.

Another essential feature to consider is the type of grinding wheels used. High-quality diamond wheels tend to last longer and provide a superior edge finish. Machines that allow easy replacement and adjustment of these grinding wheels can save time and effort, especially in a high-volume environment.

Tip: Always check for safety features such as dust collection systems and protective guards. These features not only enhance user safety but also help maintain a clean working environment. Furthermore, consider the machine's overall build quality and ease of use, which can greatly affect your workflow efficiency. Investing time in choosing the right machine will yield better results in your glass processing projects.

Analysis of Key Features in Glass Edge Grinding Machines

An Overview of Leading Global Manufacturers for Glass Edge Grinding Machines

In the realm of glass edge grinding machines, key global manufacturers play a pivotal role in shaping the industry's landscape. Companies are increasingly focusing on precision and innovation, particularly in the wake of significant market growth projections. For instance, the machine tools market is expected to reach approximately USD 196 billion by 2034, highlighting a robust CAGR of 7.5% from 2025. This growth underscores the rising demand for high-performance equipment capable of meeting the stringent requirements of modern glass processing.

Among the leaders in this field is a manufacturer renowned for advanced glass deep-processing equipment. Their products are designed to enhance optical quality and strength, a critical consideration after grinding and polishing glass edges. Recent studies emphasize the importance of grinding and polishing processes and the selection of appropriate cup wheels to achieve optimal results. As advancements continue and more innovations are unveiled at major industry events, like the recent presentations at Glasstec 2024, the competition in the glass edge processing market will undoubtedly intensify.

Performance Metrics: How Glass Edge Grinding Machines Boost Efficiency and Reduce Waste

In the realm of glass edge grinding, efficiency and waste reduction are paramount. The best glass edge grinding machines are equipped with advanced features that significantly enhance performance metrics. These machines utilize precision engineering to ensure that glass edges are ground smoothly, minimizing the amount of material wasted during the process. By optimizing speed and accuracy, manufacturers can achieve cleaner cuts and better finishes, which ultimately leads to higher quality products.

To boost productivity, it's essential to choose a machine that incorporates state-of-the-art technology. For example, look for models that integrate automated systems for consistent quality control. Additionally, machines with variable speed options can accommodate various glass thicknesses and types, enhancing versatility. Regular maintenance and calibration of the grinding machines can further ensure that they operate at peak performance.

**Tips:** When selecting a glass edge grinding machine, always consider the long-term savings that come from reduced waste. Investing in a high-quality machine may have a higher initial cost, but the efficiency gains can lead to lower operational costs over time. Furthermore, exploring eco-friendly lubricants during the grinding process can also contribute to sustainability efforts, aligning operations with contemporary recycling innovations.

What is the Best Glass Edge Grinding Machine and How Does it Work?

| Feature |

Description |

Performance Metric |

| Grinding Speed |

Speed at which the machine grinds edges of glass |

Up to 30m/min |

| Edge Quality |

Smoothness and finish of the glass edges |

Quality rating of over 95% |

| Waste Reduction |

Reduction of glass waste during the grinding process |

Up to 20% reduction |

| User Interface |

Ease of operation and control of the machine settings |

Intuitive interface with touchscreen |

| Energy Consumption |

Amount of energy the machine uses during operation |

Effective use, approx. 5 kWh per 100m |

Trends in Glass Edge Grinding Technology and Their Impact on the Industry

The glass edge grinding industry has seen significant advancements in technology, which have transformed traditional manufacturing processes. One major trend is the introduction of automated systems that enhance precision and efficiency. With the integration of robotics and computer numerically controlled (CNC) machines, manufacturers can achieve superior edge finishes and maintain consistent quality across large production runs. This shift not only reduces labor costs but also minimizes human error, leading to increased productivity and profitability.

Moreover, sustainability has become a crucial focus within the glass edge grinding sector. Manufacturers are increasingly implementing eco-friendly practices, such as utilizing water recycling systems and energy-efficient machinery. These innovations not only lower the environmental impact of glass production but also appeal to a growing consumer base that prioritizes sustainability. As companies adopt these technologies, they not only improve their operational efficiency but also strengthen their market position in an industry that is progressively leaning towards greener solutions.

Home

About Us

Products

UPVC PVC Window Machine

Aluminum Window Machine

Glass Cutting Machine

Glass Edging Machine

Insulating Glass Machine

Glass lifting machine

Glass Washing Machine

Glass Laminating Machine

Glass Sandblasting Machine

Glass Drilling Machine

CNC Glass Working Center

CNC Non-Metal Cutting Machine

The Other Glass Machinery

Application

Download

News

Contact Us