2026 Best Glass Cutting Tilting Table Features Benefits and Reviews

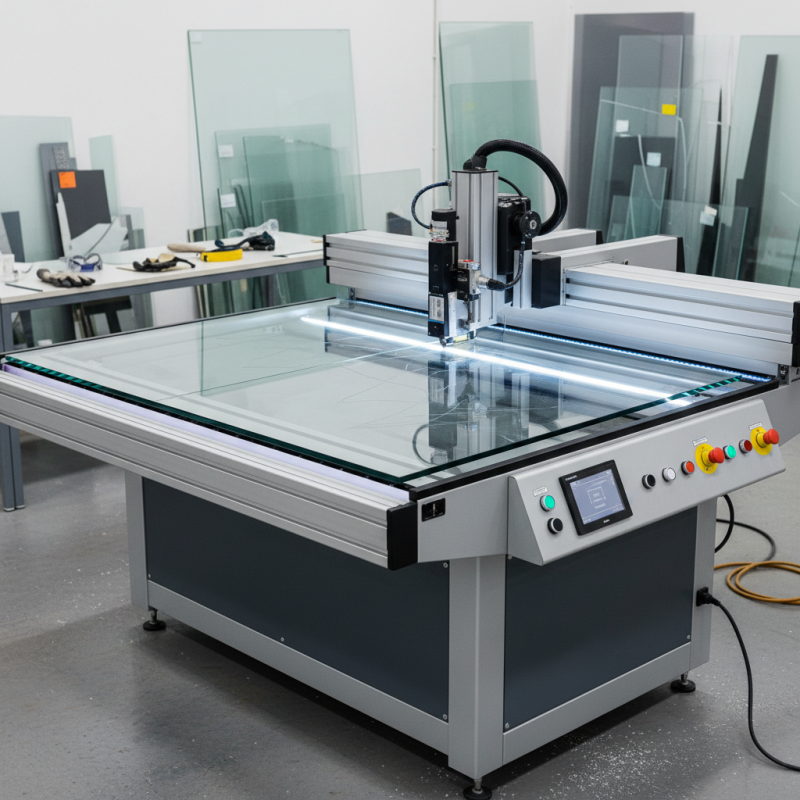

In the world of glass fabrication, efficiency and accuracy are paramount. The Glass Cutting Tilting Table addresses both needs effectively. According to industry reports, the demand for precision glass cutting tools has surged by over 30% in recent years. This increase highlights the importance of investing in quality equipment like the Glass Cutting Tilting Table.

These tables provide a practical solution for both professional glass cutters and DIY enthusiasts. They enhance work efficiency by allowing smoother and faster cuts. A recent study revealed that users experienced a 20% reduction in material waste when utilizing a tilt table. However, not all models live up to expectations. It's essential to understand the features and benefits thoroughly before making a choice.

While the industry offers various options, many still lack essential features such as stability and adjustable angles. This gap suggests the necessity for careful evaluation of available products. Quality varies widely across brands, making some tables unsuitable for heavy-duty use. Therefore, knowing the specific features of the 2026 best models will help in making an informed decision.

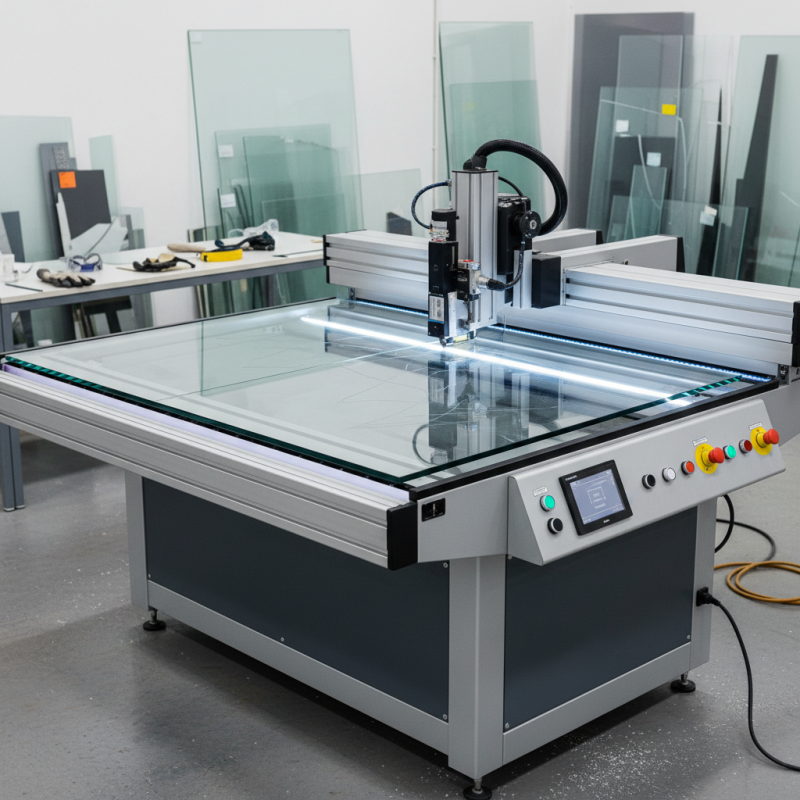

2026 Glass Cutting Tilting Table: An Overview of Key Features

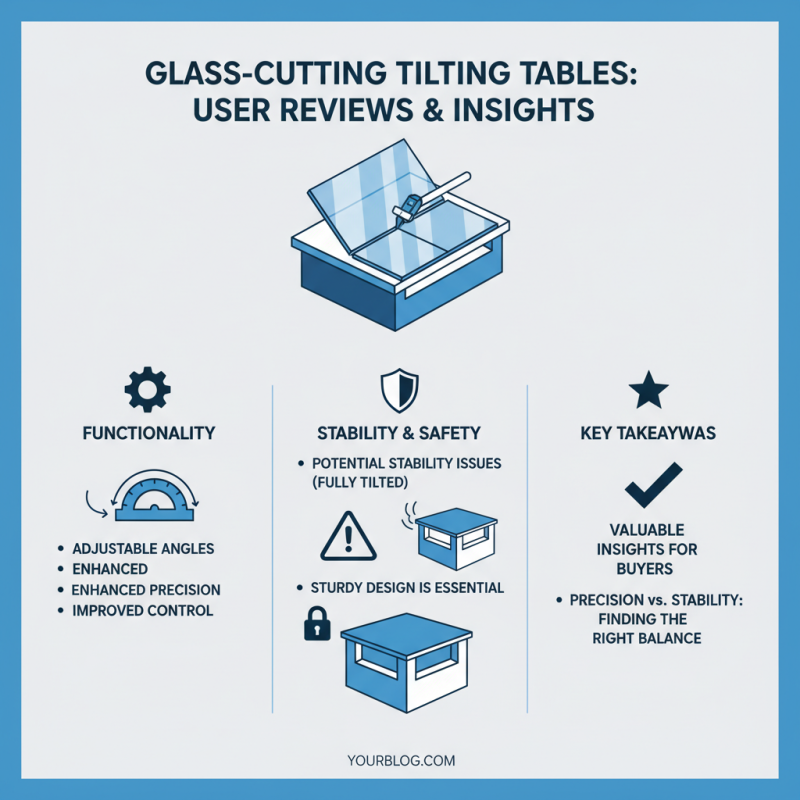

When considering a glass cutting tilting table, several key features stand out. These tables are designed for precision and ease of use. They often include adjustable angles, allowing for various cutting positions. A sturdy frame ensures stability during operation. Non-slip surfaces provide added safety while working with delicate materials. Users often appreciate how these features enhance productivity.

The benefits of a glass cutting tilting table are noteworthy. They can significantly reduce strain on your body. With the right table, your workflow becomes smoother. However, not all models are perfect. Some users report issues with the adjustment mechanism over time. Weight distribution is important as well; a poorly distributed table can lead to accidents.

Reviews highlight user experiences, both positive and negative. Many emphasize the importance of customizing the table for personal needs. Some users find the need for additional accessories to achieve optimal cutting results. It's essential to evaluate both performance and user comfort. In the end, the right choice will depend on your specific requirements.

Benefits of Using a Tilting Table for Glass Cutting Projects

A tilting table can significantly enhance your glass cutting experience. These tables provide a stable surface, reducing disruptions while working. The adjustable angle allows for precise cuts, adapting to different projects. This feature is crucial for achieving clean, edge-smooth finishes. Experienced users praise the ergonomic benefits. It reduces strain on your back and arms, especially during long sessions.

Working with glass has challenges. Mistakes can be costly. An adjustable table minimizes the chances of errors. It helps control the cutting angle better. However, it requires some practice to master. Many find their initial attempts less than perfect. Learning to find the right tilt takes time. But with patience, results improve significantly.

Finding a good balance in angle and pressure is essential. Too much tilt can lead to cracks, while too little makes cutting difficult. It's a learning curve, but this tool enhances precision over time. Investing time in mastering this table yields benefits. The quality of your projects can elevate significantly.

2026 Best Glass Cutting Tilting Table Features Benefits and Reviews

| Feature |

Description |

Benefit |

User Rating (out of 5) |

| Tilt Angle Adjustability |

Allows for various cutting angles. |

Enhances precision in cutting intricate designs. |

4.5 |

| Sturdy Construction |

Made from high-quality materials ensuring durability. |

Long-lasting use with minimal wear and tear. |

4.7 |

| Built-in Measurement Guides |

Integrated measuring system for accurate cuts. |

Saves time on measuring and increases cutting efficiency. |

4.8 |

| Height Adjustment |

Can be adjusted for user comfort. |

Reduces strain on the back and arms during cutting. |

4.6 |

| Lightweight Design |

Easy to move and transport. |

Ideal for mobile glass cutting projects. |

4.4 |

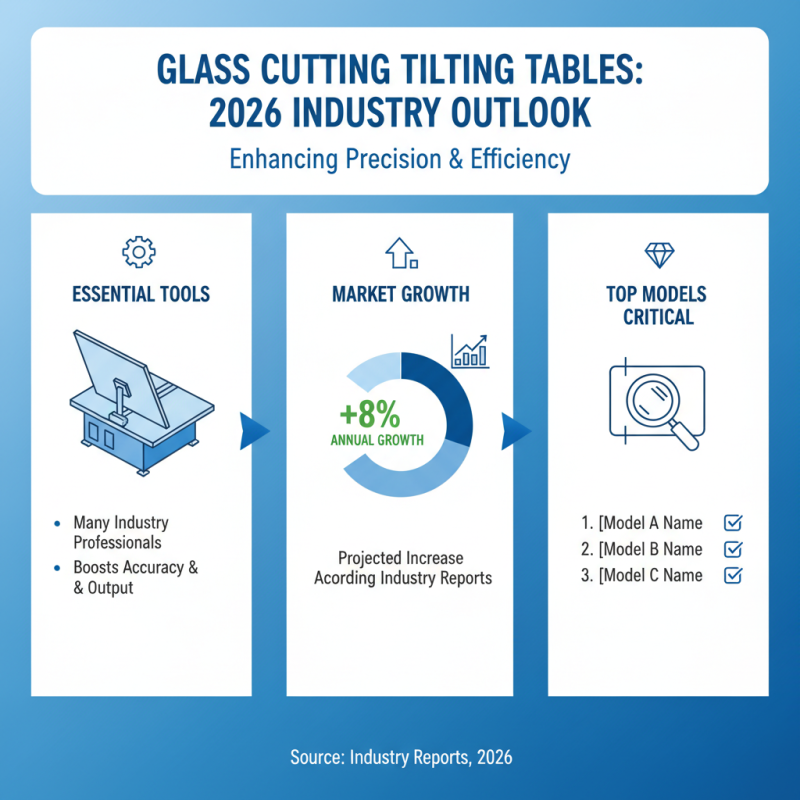

Top Brands and Models of Glass Cutting Tilting Tables in 2026

In 2026, glass cutting tilting tables are essential tools for many professionals in the industry. They enhance precision and efficiency. The market shows significant growth, with a projected increase of 8% annually according to industry reports. This makes understanding top models critical.

Leading models feature adjustable angles and sturdy surfaces. Some tables come with built-in measuring guides. These features improve accuracy during cutting tasks. However, not all tables are equally reliable. Some users report issues with stability, particularly at extreme tilting angles. Quality control varies between manufacturers. Regular assessments can help identify top performers.

User reviews highlight the importance of ease of adjustment. Difficult-to-use mechanisms can slow down work. Some tables claim quick adjustments but fail in practice. Balancing quality and cost is also a challenge for buyers. Not every table meets expectations, leading to frustration. Insights from industry studies emphasize the need for rigorous testing before purchase.

Maintenance Tips for Prolonging the Life of Your Glass Cutting Table

Maintaining your glass cutting tilting table is crucial for its longevity.

Regular cleaning is essential. Use a soft cloth and a gentle cleaner.

Avoid abrasive materials that can scratch the surface.

Check for any debris or glass shards after every project.

These tiny remnants can cause accidents later.

Proper storage also plays a significant role. When not in use, cover your table to prevent dust accumulation.

If possible, keep it in a climate-controlled area.

Humidity can warp the table over time.

This can lead to uneven cutting surfaces, which are frustrating and dangerous.

Inspect your table regularly. Look for signs of wear or damage.

If you notice any issues, address them immediately.

An unstable surface can lead to poor results.

It is better to reflect on what went wrong rather than ignore small problems.

Taking small steps can significantly enhance your table's lifespan.

Home

About Us

Products

UPVC PVC Window Machine

Aluminum Window Machine

Glass Cutting Machine

Glass Edging Machine

Insulating Glass Machine

Glass lifting machine

Glass Washing Machine

Glass Laminating Machine

Glass Sandblasting Machine

Glass Drilling Machine

CNC Glass Working Center

CNC Non-Metal Cutting Machine

The Other Glass Machinery

Application

Download

News

Contact Us